Color Coating Aluminium Coil PE Painting for Inside Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Color Coating Aluminium Coil PE Painting for Inside Doors

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Color Coating Aluminium Coil PE Painting for Inside Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminium Coil PE Painting for Inside Doors

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

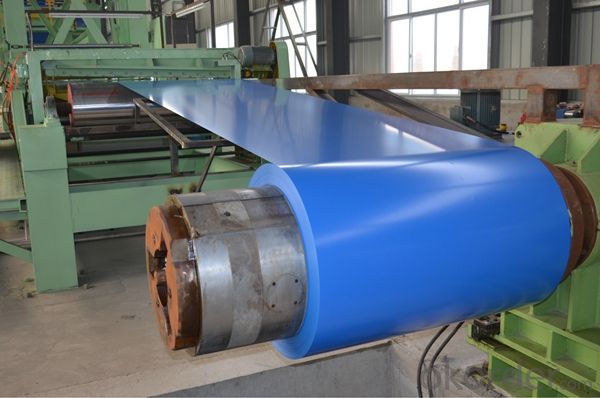

5. Image of Color Coating Aluminium Coil PE Painting for Inside Doors

6. Package and shipping of Color Coating Aluminium Coil PE Painting for Inside Doors

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Aluminum inventory of the company, placed for a little longer, there will be surface oxidation, white spot shape, after cleaning into black spots, affecting the use of. Is there a better and convenient way to save it?

- In general, aluminum itself. You said that the antioxidant warehouse is wet, there are other acidic substances damage the alumina compact protection film. Aluminum volume convenient paint, or wrapped in a plastic film, the best conditions inside the silicon desiccant

- Q:What are the different coil slitting widths available for aluminum coils?

- The different coil slitting widths available for aluminum coils vary depending on the specific requirements and industry standards. Generally, aluminum coils can be slit into various widths ranging from as narrow as 0.5 inches to as wide as 72 inches or even wider. The exact range of available coil slitting widths is determined by the equipment and capabilities of the coil slitting facility. These coil slitting widths cater to different applications and industries such as automotive, construction, packaging, and electronics. Some common coil slitting widths for aluminum coils include 12 inches, 24 inches, 36 inches, and 48 inches. However, it is important to note that custom slitting widths can also be requested to suit unique project needs.

- Q:I was going to buy a turkey roaster pan today and an elderly couple stopped me and told me to buy another one that was made of stainless steel instead of aluminum because aluminum does something to your brain. What is the story?Just curious. Does this also ring true for using a sheet of aluminum foil over baking sheets while cooking cookies or fries or something? I always coat my cookie sheets with foil. Just curious...

- They were talking about Alzheimer's disease, there is a correlation between aluminum and the disease. Lots of things have it as an ingredient - baking powder, all sorts of stuff. I don't think a pan used 1 or 2 times a year will be harmful, but who knows? I got rid of my aluminum pots. I make piles of cookies at xmas, it is no big deal to wash the pan. It takes about 2 seconds and a tiny bit of elbow grease.

- Q:How are aluminum coils used in the production of HVAC ductwork?

- Aluminum coils play a significant role in the production of HVAC ductwork. These coils are made from high-quality aluminum material that is lightweight, durable, and corrosion-resistant, making them ideal for use in HVAC systems. The first step in utilizing aluminum coils for HVAC ductwork production is the manufacturing process. The coils are initially rolled into thin sheets, which are then cut into specific widths and lengths to match the size requirements of the ductwork. This flexibility in sizing allows for customized ductwork that fits perfectly in various HVAC systems. Once the aluminum coils are cut into the desired dimensions, they are then formed into the shape of the ductwork. This can be done through a variety of methods, such as bending, folding, or rolling, depending on the design and specifications of the ductwork. One of the key advantages of using aluminum coils in HVAC ductwork production is their excellent thermal conductivity. Aluminum is a highly effective heat conductor, which means that it can efficiently transfer heat or cold air throughout the HVAC system. This property is essential for the proper functioning of the ductwork, as it helps maintain the desired temperature in different areas of a building. Moreover, aluminum coils are known for their resistance to corrosion, which is crucial in HVAC systems. The coils are exposed to various elements, including moisture, which can lead to rust and deterioration in other materials. Aluminum, on the other hand, naturally forms a protective oxide layer that prevents corrosion, ensuring the longevity and reliability of the HVAC ductwork. Furthermore, the lightweight nature of aluminum coils makes them easy to handle and install. This reduces the labor and time required for ductwork installation, resulting in cost savings for both manufacturers and installation teams. Additionally, the lightweight nature of aluminum coils reduces the overall weight of the HVAC system, making it more energy-efficient and reducing the strain on other components. In conclusion, aluminum coils are an essential component in the production of HVAC ductwork. Their lightweight, durable, and corrosion-resistant properties, along with excellent thermal conductivity, make them ideal for efficiently transferring air throughout the HVAC system. Additionally, the flexibility in sizing and ease of installation further contribute to their widespread use in the HVAC industry.

- Q:Are aluminum coils resistant to impact damage?

- Yes, aluminum coils are generally resistant to impact damage. Aluminum is known for its high strength-to-weight ratio and excellent durability, which makes it less susceptible to impact damage compared to other materials. Additionally, aluminum coils are often used in various industries where they are exposed to various environmental conditions and handling processes, and they are designed to withstand such impacts without getting damaged easily. However, it is important to note that the level of resistance to impact damage can vary depending on the specific thickness, quality, and design of the aluminum coil.

- Q:What are the fire resistance properties of aluminum coils?

- Aluminum coils have excellent fire resistance properties due to the inherent characteristics of aluminum, such as its high melting point and low flammability. Aluminum does not burn, but instead forms a protective oxide layer on its surface when exposed to heat or flames. This oxide layer serves as a barrier, preventing further oxidation and combustion. Additionally, aluminum has a high thermal conductivity, which helps to dissipate heat quickly, further reducing the risk of fire. Overall, aluminum coils are considered to be highly resistant to fire.

- Q:Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum is a lightweight and corrosion-resistant material that has excellent thermal conductivity. These properties make it suitable for various applications where low-friction is desired. In industries such as automotive, aerospace, and HVAC systems, aluminum coils are often used in heat exchangers, evaporators, condensers, and cooling coils. These coils are designed to efficiently transfer heat, while minimizing friction and energy loss. Additionally, aluminum coils can be used in electrical motors, generators, and transformers, where low friction is essential for smooth operation and reduced energy consumption. The lightweight nature of aluminum also helps to reduce the overall weight of the system, leading to improved efficiency. Furthermore, aluminum coils can be utilized in various types of machinery and equipment that require low friction, such as conveyor systems, sliding mechanisms, and bearings. Aluminum's low coefficient of friction allows for smooth and efficient movement, minimizing wear and tear on the components. Overall, aluminum coils are a versatile solution for low-friction applications due to their lightweight, corrosion-resistant, and thermally conductive properties. Their use can lead to improved energy efficiency, reduced maintenance costs, and enhanced performance in a wide range of industries.

- Q:I am sanding tool marks out of aluminum rims and plan on polishing them. Any help to make sanding them easier would be welcome.

- If they are cast with a rough finish, take them somewhere that does walnut shell blasting and have them blasted. Sand blasting and bead blasting will take off too much metal. If they are smooth, use 400 grit wet-or-dry with water, then 600, then get a jar of Mother's Mag Polish (or equivalent) and polish with a soft cloth until it has the luster you want. If you want it to look brushed, rub it with a scotchbrite pad, always keeping the same direction on your strokes.

- Q:for purchasing aluminium are the grades to be mentioned

- Aluminum alloy designations are described by a 4-digit index system. The first digit indicates the alloy group according to the major alloying elements. 1XXX - 99% Al with no major alloying element. 2XXX – copper 3XXX – Manganese 4XXX – Silicon 5XXX – Magnesium and silicon 7XXX – Zinc 8XXX – other element Experimental alloy designations have an “X” prefix Aluminum temper designations (suffixes) describe heat-treatable and non heat-treatable alloys.

- Q:I want to remove melted aluminium piston material from an engine cylinder with burning a hole in the cylinder!

- Aluminum reacts with sodium hydroxide, and will dissolve in a basic solution, while the steel cylinder liner will be unaffected...in theory. This is totally impractical though. You need to machine out the damaged piston, either by boring or grinding the material away.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coating Aluminium Coil PE Painting for Inside Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords