Color Coated Steel Sheet (ASTM A755) for Constructions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:Ral 3012

Standard:AISI

Steel Grade:ASTM A755

Surface Treatment:Coated

Technique:Cold rolled, Hot dipped, Pre-painted

Export Markets:Global

Additional Info.

Packing:Standard Sea Worthy Package

Standard:ASTM A755

Origin:China

HS Code:72107000

Production Capacity: 18, 000~25, 000 Tons Per Month.

Product Description

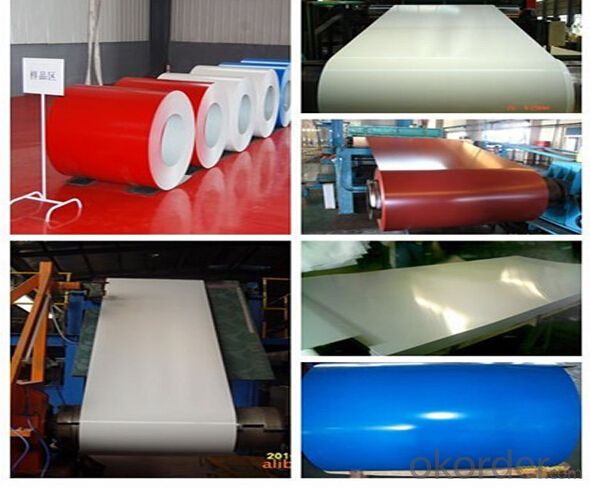

NAME: Prepainted Steel Coil\Colour Coated Coil\Coil coated steel\PPGI

SIZE:

Thickness: 0.18-1.50mm

Width: 10mm-1500mm(STD914mm,1000mm, 1200mm, 1219mm, 1250mm, 1500mm)

Thickness tolerance: +/-0.05 mm

Width tolerance: -2.0/5.0mm

ZINC, PAINT & COLOR:

Zinc coating: 60-275G/M2

Paint thickness: Top 15-25um + Back 5-10um

Paint: polyester, silicone polyester, acrylic, fluoropolymer, plastisol, or polyurethane

Color: As the RAL color standard or customer's sample

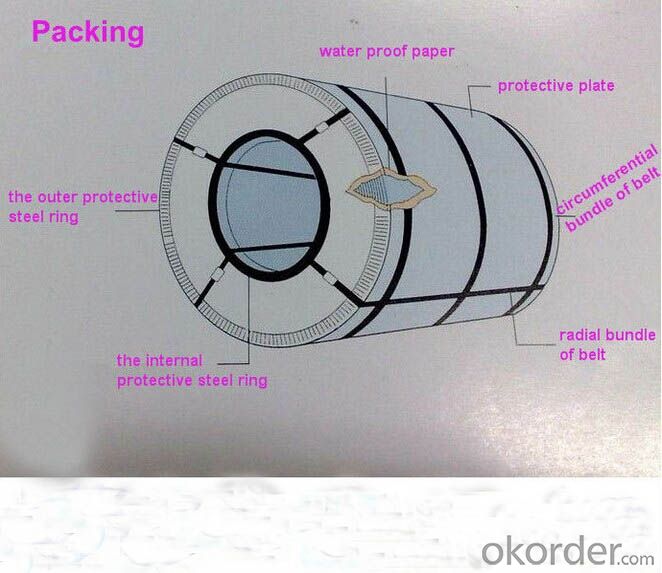

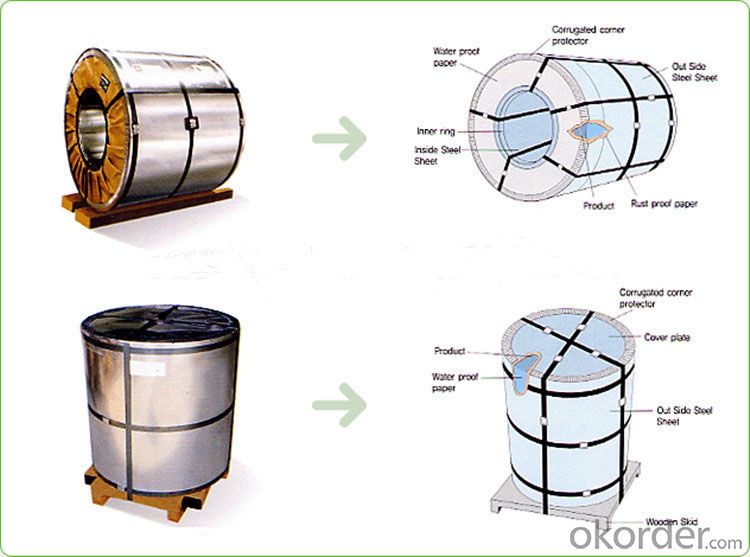

PACKING:

Coil weight: 3-10tons

ID: 508mm\610mm

Standard sea worthy package

STANDARD:

JIS G 3312, ASTM A755, EN10169,GB/T2518

Base sheet: SGCC, CGCC, DC51D+Z, Q195,etc

Quality: CQ DQ

Lifespan: 10-15 years

APPLICATION:

Outdoor: Roof\ Roof structure\Surface sheet of balcony\ Frame of window\Door\Door of garage\Roller shutter door\Booth\Persian blinds\Cabana\Refrigerated wagon and so on.

Indoor: Door\Isolater\Frame of door\Light steel structure of house\Sliding door\Folding screen\Ceiling\ Internal decoration of toilet and elevator.

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C,

Acceptable price term?

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q:Are they made using the same processes, or is tempered steel made without the quenching process?

- Hardening is the preliminary process. The fully hardened state may be far too brittle for practical use. The tempering process is tailored to reduce the actual hardness, to introduce more flexible alloys. The tempering method employed may be done at relatively low temperatures, but some alloys require prolonged soaking at elevated temperatures. Some may be cooled in air, but others may require quenching to end the process.

- Q:How are steel coils used in the manufacturing of tools?

- Steel coils are used in the manufacturing of tools as they provide a strong and durable material that can be shaped and formed into various tool components. These coils are typically cut, bent, and shaped to create the desired tool design, and then further processed and treated to enhance their strength and performance. Additionally, steel coils are often used for tool handles, as they provide a sturdy grip and long-lasting durability.

- Q:How are steel coils protected against fire and heat?

- Steel coils are typically protected against fire and heat through various methods such as fire-resistant coatings, fire blankets, water-based sprays, or the use of fire-resistant barriers or walls in the storage area. Additionally, fire detection and suppression systems, such as sprinkler systems, are often installed to quickly extinguish any potential fire.

- Q:I was cutting a sheet of steel with an angle grinder when suddenly the rate at which the blade was cutting slowed way down. I tried a few different things, and turned off the tool and looked at the blade. It didn't look damaged, but it definitely was not cutting as quickly. I thought either I had hit a harder section of steel (is that possible? It looked pretty uniform) or the blade had lost it's abrasive quality or something. Also, before this happened I had accidentally cut into the wooden sawhorse that was holding up the steel sheet, but I've done that before with no problem. After a short while the problem fixed itself and the rate of cutting went back to a fast normal. Anyone know why this happened?

- Your blade was overheated. Change it into diamond blade shall do.

- Q:How are steel coils used in the production of construction components?

- Steel coils are used in the production of construction components by being processed into various shapes and sizes, such as beams, columns, and plates. The coils are unwound and then cut, bent, or shaped to meet the specific requirements of the construction project. Additionally, the high strength and durability of steel make it a preferred material for construction, ensuring the components can withstand heavy loads and harsh environmental conditions.

- Q:How are steel coils used in the manufacturing of construction cranes?

- Steel coils are used in the manufacturing of construction cranes to form the structural components, such as the boom, mast, and jib. These coils are processed and shaped through a series of cutting, bending, and welding techniques to create the strong and durable framework necessary for the crane's operation.

- Q:How are steel coils coated?

- Steel coils are coated through a process called coil coating, where the steel is cleaned, treated, and then coated with a protective layer using techniques such as roll coating or spray coating.

- Q:What processes and materials are used in the production of chrome steel

- Go to the process section and find point 6 (explains when alloys are added). Chrome is added at this point, usually in the form of ferrochrome alloy (FeCr). Many kinds of chrome steel also contain nickel. The strengthening effect on steel by forming stable carbide grains at the grain boundaries and the strong increase in corrosion resistance made chromium an important alloying material for steel. The high speed tool steels contain between 3 and 5% chromium.

- Q:How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various applications. They are commonly used in the production of appliances, automotive parts, construction materials, and packaging materials. The coils can be shaped, cut, and formed into different components or structures, providing strength, durability, and versatility to the end products.

- Q:My neighbor who has an older model mustang installed a steel clutch in it and has blown 4 transmissions as a result.Can any mechanic explain why a steel clutch would kill transmissions? What other modifications would the car need in order to prevent this?

- First of all it's not really a steel clutch..it is called a sintered iron clutch disk... a sintered iron clutch has a very aggressive amount of friction and is generally only used in racing application because of this...also it is ushually a non sprung disk. all of these factors = a very abrupt ingagement of the clutch which will shock the driveline very badly...say he's making 400hp and has really sticky tires..there is bound to be a weak link between the engine and the tires, in a factory driveline this would probably have been the clutch(it would slip) but since he has upgraded it he has now found the next weekest llink..in this case the transmission, he either needs to look into a beefier box or not launch the car so hard.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Steel Sheet (ASTM A755) for Constructions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords