Color Coated Galvanized Steel Coils PPGI/PPGL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Surface Treatment:Coated

Technique:Galvanized

Standard:JIS

Application:Container Plate

Edge:Mill

Stock:Stock

Steel Grade:CGCC, Dx51d, SGCC

Color:Ral 1015, 5002, 6005, 8017, 9002, 9006, 9010 etc.

Thickness:0.16-1.0mm

Width:914/1000/1200/1219/1220/1250mm

Base Metal:Galvanized or Galvalume Steel

Zinc-Coating:Z50-150G/M2 or Az40-100G/M2

ID Coil:508mm

Coil Weight:3-5 Mt

Painting:20-25miu on Top / 5-8miu on Back

Type of Coating:PE Smp PVDF

Export Markets:North America, South America, Southeast Asia, Eastern Asia

Additional Info.

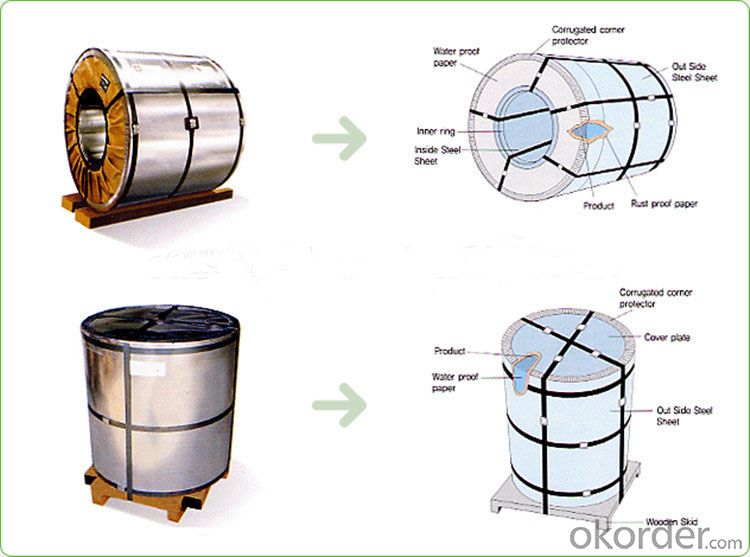

Packing:Standard Export Seaworthy Packing In20′′ Container

Standard:0.14-1.0*914-1250*C

Origin:China

HS Code:72107010

Production Capacity:100000tons Per Year

Product Description

Color-coated Galvanized/Galvalume Steel Coil (PPGI/PPGL)

1. Techinical standard: EN10169

2. Grade: TDX51D, TSGCC

3. Color: Ral standard or according to customers' requirment

4. Thickness: 0.14-1.0mm (0.16-0.8mm is the most advantage thickness)

5. Width: 600-1250mm (610/724/820/914/1000/1200/1219/1220/1250mm)

6. Base metal: Galvanized / galvalume steel

7. Finish Painting: 15-20miu PE on top 5-8miu EP on back

8. Color: Ral standard

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q:How are steel coils used in the production of elevator components?

- Steel coils are used in the production of elevator components to manufacture various structural and mechanical parts. These coils are typically formed, shaped, and cut to create components such as elevator guide rails, brackets, frames, and support structures. The high strength and durability of steel make it an ideal material for these components, ensuring the safety and reliability of elevators.

- Q:How are steel coils used in the manufacturing of power generation equipment?

- Steel coils are used in the manufacturing of power generation equipment as they are shaped and formed into various components such as turbine blades, casings, and structural supports. The strength and durability of steel make it suitable for withstanding high temperatures and pressures, ensuring the reliability and longevity of the equipment. Additionally, steel coils are often used in the production of electrical transformers and generator cores, providing a magnetic circuit that efficiently converts mechanical energy into electrical energy.

- Q:I believe steel is stronger but it steel lighter than iron too?

- Steel is iron, with other things added that strengthen it and/or make it less rust liable. So, in general, steel is stronger than iron. In so far as the density, that depends on the steel alloy. Some are higher than iron, some lower. Remember there are hundreds of different steel alloys. edit: but the density is still close to that of iron. density steel 7750 to 8050 kg/m? density iron 7870 kg/m?

- Q:What are the different methods of skin pass rolling for steel coils?

- There are several methods of skin pass rolling for steel coils, each with its own unique characteristics and benefits. Some of the most common methods include: 1. Dry Skin Pass: In this method, the steel coil is passed through a set of rolls without the application of any lubricant or coolant. This helps to improve the surface finish of the steel by reducing the thickness variations and imparting a smoother texture. 2. Wet Skin Pass: This method involves the application of a water-based emulsion or coolant during the skin pass rolling process. The coolant helps to reduce friction and heat generated during rolling, resulting in improved surface quality and reduced risk of surface defects. 3. Electrolytic Skin Pass: This technique utilizes an electrolytic solution during skin pass rolling. The steel coil is immersed in the solution, and an electric current is applied to the coil, resulting in controlled surface etching. This method is particularly effective in improving surface cleanliness and removing oxide scale. 4. Temper Mill Skin Pass: This method combines skin pass rolling with a tempering process. The steel coil is rolled through a series of rolls, followed by a heating and cooling process to achieve the desired mechanical properties and surface finish. This method is commonly used for high-strength and automotive-grade steel coils. 5. Tension Leveling: In this method, the steel coil is passed through a series of rolls under high tension. This elongates the steel and helps to reduce residual stresses and shape defects, resulting in improved flatness and dimensional stability. It is important to note that the choice of skin pass rolling method depends on factors such as the desired surface finish, required mechanical properties, and the type of steel being processed. Each method has its own advantages and limitations, and manufacturers typically select the most appropriate method based on their specific requirements.

- Q:What are the common methods of preserving steel coils?

- Some common methods of preserving steel coils include applying protective coatings, such as oil or paint, to prevent corrosion and rust formation. Another method is using VCI (Vapor Corrosion Inhibitor) paper or film, which releases chemicals that prevent oxidation. Additionally, steel coils can be stored in climate-controlled environments or wrapped in moisture-resistant materials to minimize exposure to moisture and humidity, which can accelerate corrosion.

- Q:My daughter wants a pair of steel toe cap boots for around the horses but wants them warm, so ideally fur lined etc. Does anybody know where I could purchase them as everywhere I look its only one or the other, cant get steel with fur lining. Very frustrating. I live in the uk. Many thanks.

- The steel toe cap wishes to be equipped for the duration of manufacture for the boots to arrive the desired standards. It could be nice if you looked at one of the PPE sites and see if you will see a pair that you may dye or paint.

- Q:Iron too heavy for Ulysses but if there was any iron used id imagine it was steel. Can steel go deeper into sun than iron? Compare two bolts.. 1steel 1iron..is there a difference to what the steel can do?

- Dont understand are you going to put them in sun ? Sun made from gas wich is on fire. Its impossible to get to the sun and not to get burn. Steel is really more solid and strong than iron so its more hard to break it or to bend. But in camparing of fusion temperature - iron is a bit more better, though it would not make a big difference .From metals - tungsten has the highest fusion temperature - near to 3400 C . Iron is near to 1530 C, steel is near to 1300 -1500 C. So according to this tungsten can go most close to sun. Right near the sun temperature is millions of degrees so anything will fuse and burn there.

- Q:How are steel coils used in the production of building facades?

- Steel coils are used in the production of building facades as they provide a durable and versatile material for creating structural components such as panels, cladding, and roofing. The coils are processed and shaped into the desired form, allowing for easy customization and installation. The strength and resistance of steel make it an ideal choice for facades, ensuring long-lasting and aesthetically pleasing buildings.

- Q:How do steel coils impact the overall cost of production?

- Steel coils have a significant impact on the overall cost of production in a variety of industries. Firstly, the cost of steel coils themselves can be a significant expense. The price of steel is influenced by various factors such as supply and demand, raw material costs, and market fluctuations. Any increase in the cost of steel coils can directly impact the overall production cost, as it becomes a major component in the manufacturing process. Moreover, steel coils also affect the operational costs of production. They are typically used in various manufacturing processes, such as stamping, rolling, and forming, which require specialized machinery. The durability, quality, and size of the steel coils play a vital role in determining the efficiency and effectiveness of these processes. If the steel coils are of low quality or not suitable for the specific production requirements, it can lead to increased downtime, machinery maintenance, and rework, all of which contribute to higher production costs. In addition, transportation costs associated with steel coils can also impact the overall cost of production. Steel coils are usually heavy and bulky, necessitating special handling and transportation arrangements. The distance between the supplier and the production facility, as well as the mode of transportation, can significantly influence the logistics costs. Any increase in transportation expenses, such as fuel prices or shipping fees, can directly impact the overall cost of production. Lastly, the availability of steel coils can also impact production costs. In times of high demand or limited supply, the price of steel coils may increase, leading to higher production costs. Furthermore, if there is a shortage of steel coils due to factors like trade restrictions or disruptions in the supply chain, manufacturers may have to resort to alternative materials or sources, which could be more expensive or lower in quality. These factors can have a cascading effect on the overall cost of production. Overall, steel coils have a significant impact on the overall cost of production. Their cost, quality, transportation, and availability all influence the efficiency, effectiveness, and affordability of the manufacturing process. Therefore, manufacturers need to carefully consider and manage these factors to optimize their production costs and maintain competitiveness in their respective industries.

- Q:How are steel coils used in the production of fencing materials?

- Steel coils are used in the production of fencing materials by being unwound and flattened to create the wire used for fencing. The steel wire is then further processed and shaped into different forms, such as chain link or barbed wire, to meet specific fencing needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Galvanized Steel Coils PPGI/PPGL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords