Color Coated Aluminum Coil with Various Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Color Coated Aluminum Coil with Various Thickness

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

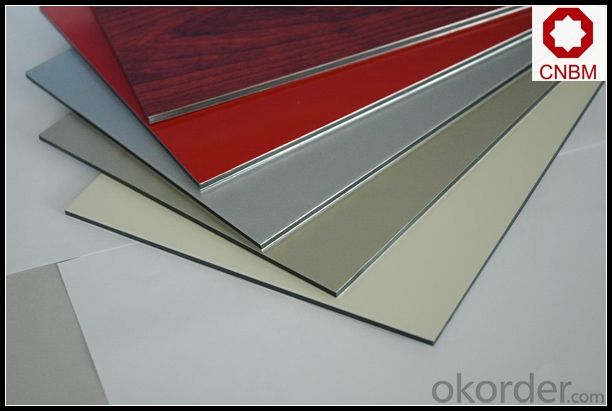

2. Application of Color Coated Aluminum Coil with Various Thickness

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminum Coil with Various Thickness

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

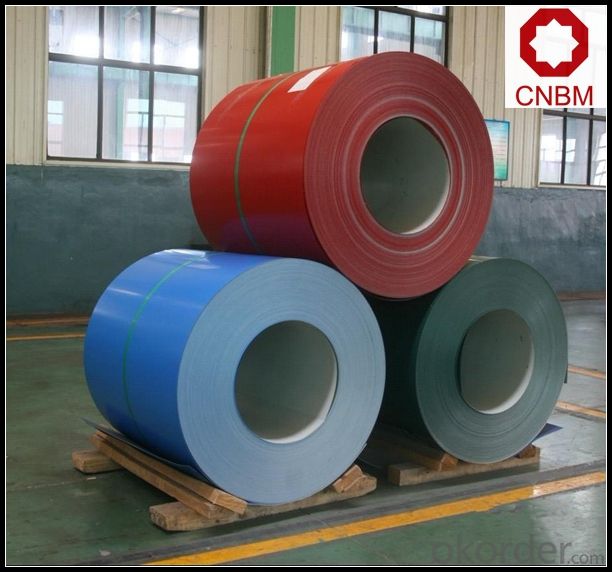

5. Image of Color Coated Aluminum Coil with Various Thickness

6. Package and shipping of Color Coated Aluminum Coil with Various Thickness

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:11 g of aluminum at 200 C and 19 g of copper are dropped into 55 cm^3 of ethyl alcohol at 15 C. The temperature quickly comes to 24 C. What was the initial temperature of the copper? (answer in C) Express your answer using two significant figures.

- Example Problem Statement: An aluminum wing on a passenger jet is 29 m long when its temperature is 29°C. At what temperature would the wing be 7 cm (0.07 m) shorter? Step 1: Write down what you know in symbolic form: The wing is made of aluminum, therefore: α = 25 x 10-6 /oC Length: l = 29 m Temperature: T1 = 29 oC Change in length: Δl = -7 cm (-0.07 m) Step 2: Write down what you don't know in symbolic form: Temperature: T2 = ? oC Step 3: Find an equation that contains what you know and what you don't know: Δl = αlΔT = αl(T2 - T1) Step 4: Solve the equation for what you don't know: Δl = αl(T2 - T1); divide both sides by αl Δl/ αl = (αl/ αl )(T2 - T1) = T2 - T1; add T1 to both sides Δl/αl + T1 = T2 - T1 + T1 = T2 Δl/ αl + T1 = T2 Step 5: Plug in (substitute) what you know and you will find out what you don't know: Δl/ αl + T1 = T2 = (-0.07 m)/( 25 x 10-6 /oC x 29 m) + 29 oC = -96.551 oC + 29 oC = -67.551 oC = -67.6 oC rounded off.

- Q:Are aluminum coils suitable for coil coating applications?

- Indeed, coil coating applications find aluminum coils to be a suitable option. Aluminum, owing to its outstanding resistance to corrosion, lightweight composition, and impressive strength-to-weight ratio, enjoys extensive usage in coil coating. Moreover, its high malleability facilitates effortless shaping and molding throughout the coil coating procedure. Furthermore, aluminum coils can be coated with an array of paints and coatings, offering a diverse selection of colors and finishes. To sum up, aluminum coils are a favored preference for coil coating applications due to their adaptability, longevity, and visually pleasing attributes.

- Q:What are the safety considerations when working with aluminum coils?

- To ensure the well-being of workers and prevent accidents, there are several safety considerations that must be taken into account when working with aluminum coils. First and foremost, workers must wear the necessary personal protective equipment (PPE) such as gloves, safety glasses, and protective clothing. This is crucial in safeguarding against cuts, abrasions, and burns that may occur during the handling of sharp edges or the coil manufacturing process. Proper storage of aluminum coils is also essential in preventing potential hazards. It is important to stack the coils in a stable manner, taking into consideration the weight and height of the stack. Additionally, they should be stored in a well-ventilated area to avoid the accumulation of flammable gases or vapors. Awareness of the potential risks associated with aluminum is paramount when working with the material. Aluminum is combustible, and factors like high temperatures and contact with sparks or open flames can heighten the risk of fire. Therefore, it is crucial to maintain a clean work area, free from any flammable materials or sources of ignition. Furthermore, handling aluminum coils with care is necessary to avoid injuries. Due to their weight, proper lifting equipment or techniques should be employed to prevent strains or musculoskeletal injuries. Workers must be trained in proper lifting techniques and be mindful of their physical limitations to prevent accidents. When it comes to cutting or shaping aluminum coils, it is imperative to use appropriate tools and machinery. Workers must receive training on the safe operation of these tools and machinery to avoid injuries. Regular inspection and maintenance of the equipment are also important to ensure their safe functioning. Lastly, following proper handling and disposal procedures for aluminum coils is essential. This may involve considering recycling options to minimize waste and environmental impact. In conclusion, safety considerations when working with aluminum coils encompass wearing appropriate PPE, proper storage, awareness of fire hazards, careful handling, the use of suitable tools and machinery, and adherence to proper handling and disposal procedures. By adhering to these safety measures, the risk of accidents and injuries can be significantly reduced.

- Q:What are the different surface finishes available for aluminum coils?

- There are several different surface finishes available for aluminum coils, including mill finish, brushed finish, embossed finish, anodized finish, and painted finish.

- Q:Why is the hard drive made of aluminum? Why is steel not used, despite being cheaper?

- Aluminum does not rust or corrode under normal circumstances and if anodized it is already oxidized and covered with the second hardest naturally occurring material on earth alumina , in its gem form it is known as ruby or sapphire.

- Q:I wrap everything with aluminum foil and bake it in the oven -- fish, meat, vegetables. Is this really safe? Or safe when done occasionally? Or should I find a new way?

- Perfectly safe to use aluminum foil in the oven..........NOT so much in the microwave, lol. :)

- Q:I heared the aluminum weakens or melts.

- Mercury readily combines with aluminium to form a mercury-aluminum amalgam when the two pure metals come into contact. However, when the amalgam is exposed to air, the aluminium oxidizes, leaving behind mercury. The oxide flakes away, exposing more mercury amalgam, which repeats the process. This process continues until the supply of amalgam is exhausted, and since it releases mercury, a small amount of mercury can “eat through” a large amount of aluminium over time, by progressively forming amalgam and relinquishing the aluminium as oxide. Aluminium in air is normally protected by a thin layer of its own oxide, which is not porous to mercury. Mercury coming into contact with this oxide does no harm. However, if any elemental aluminium is exposed (even by a recent scratch), the mercury may combine with it, starting the process described above, and potentially damaging a large part of the aluminium before it finally ends.

- Q:What is the role of aluminum coils in HVAC systems?

- The role of aluminum coils in HVAC systems is to transfer heat between the indoor and outdoor units. These coils contain refrigerant that absorbs heat from the indoor air, which is then transferred to the outdoor coil to be released. This process allows for efficient cooling or heating of the indoor space.

- Q:How do aluminum coils compare to copper coils?

- Coils made of aluminum and copper are commonly used in various applications, including heating, ventilation, and air conditioning (HVAC) systems. While aluminum and copper have their own advantages and disadvantages, there are notable distinctions between the two types of coils. First and foremost, cost is a significant factor. Generally speaking, aluminum is cheaper than copper, making it a more cost-effective option for specific applications. However, it is important to acknowledge that the cost of copper has decreased in recent years, resulting in a narrower price difference between the two materials. Another distinguishing feature is heat transfer efficiency. Copper is a better conductor of heat compared to aluminum, which means that copper coils have superior heat transfer capabilities. This leads to more efficient cooling or heating, resulting in lower energy consumption and potentially reduced operating costs. Conversely, aluminum coils have a higher thermal expansion rate, which can cause increased stress on the system over time. Durability is another aspect to consider. Copper is renowned for its durability and resistance to corrosion, making copper coils more reliable and long-lasting. On the contrary, aluminum is more susceptible to corrosion, particularly in areas with high humidity or exposure to saltwater. Nevertheless, advancements in coating technologies have enhanced the corrosion resistance of aluminum coils, making them suitable for numerous applications. Lastly, the weight of the coils is worth mentioning. Aluminum coils are significantly lighter than copper coils, making them easier to handle and install. This can be advantageous in situations where weight is a concern, such as in mobile or portable HVAC units. In conclusion, aluminum coils and copper coils possess their own distinctive characteristics and advantages. Aluminum coils are generally more cost-effective and lighter, but may have lower heat transfer efficiency and be more susceptible to corrosion. Copper coils, on the other hand, offer superior heat transfer, improved durability, and resistance to corrosion. The choice between the two materials ultimately depends on the specific requirements and priorities of the application.

- Q:How are aluminum coils inspected for defects?

- Aluminum coils are inspected for defects through various methods such as visual inspection, ultrasonic testing, eddy current testing, and X-ray inspection. These techniques help identify surface imperfections, cracks, porosity, and other defects that may affect the quality and integrity of the coils.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminum Coil with Various Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords