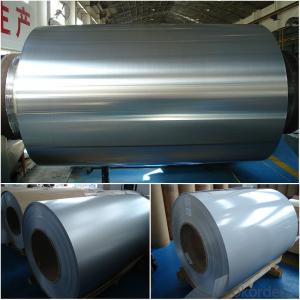

color coated aluminum coil for ACP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color coated aluminum coil isa material with excellent acid-resistance and alkali-resistance. The coating layeris even with bright color to last for a very long time. It is a greendecoration material with the characters of environment protection,flame-resistance, and groovy colors. In nowadays, the color coatedaluminum coil has become the popular material for top grade decoration. With our advance professional aluminum coated technique, wecan custom various aluminum coils ,like coated aluminum coil , Color coatedaluminum coil , embossed aluminum sheet with the color and size which youdemands.

1)Process: pre-treatment, continuous painting and baking for times .

2)Material: high quality material, aluminum sheets from South West AluminumIndustry Company in China, pre-treatment material from Henkel & Chemtellfrom Germany, more than 70% of PVDF coating from PPG Corp., the USA andpolyester from Sweden Becker Industrial Coating Co., Ltd.

3) Ourproducts can keep excellent quality and stability.

4)Thickness: 0.06 - 1.0mm; width: 20 - 1,590mm

Applications:

The aluminum coils are widely used in ACP/curtainpanel/honey comb panel/shutter/roofing and most of the decoration areas. Withthe superior quality and advanced management, our products had been export toEuro/North America /East Asia and many other areas and countries.

PEAluminum Coating Coils for ACP

Featuresof PE Aluminum Sheet:

1.Adopting precision rolling coating technology, our PVDF and PE coated coil canensure excellent adhesive without coating omission.

2. For thePE coated aluminum coil we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wallpanels, advertisement boards, counters, home appliances, decoration in and outof autos and boats.

Performance of thecoating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q:Can aluminum coils be used for roofing applications?

- Absolutely! Roofing applications can definitely make use of aluminum coils. Aluminum is widely preferred as a roofing material owing to its array of benefits. Its lightweight nature simplifies transportation and installation processes. Additionally, aluminum boasts exceptional durability and resistance against corrosion, guaranteeing an extended lifespan for the roof. Furthermore, it is an ideal choice for regions with high humidity or coastal areas, as it does not succumb to rust. Moreover, aluminum roofing proves to be energy-efficient as it effectively reflects sunlight and heat, thus reducing cooling expenses. All in all, thanks to their robustness, longevity, and energy efficiency, aluminum coils make an outstanding choice for roofing applications.

- Q:How are aluminum coils used in the manufacturing of appliances?

- Aluminum coils are widely used in the manufacturing of appliances due to their unique properties and versatility. They are primarily used in the production of heat exchangers, which are essential components in appliances such as refrigerators, air conditioners, and heaters. One of the main advantages of aluminum coils is their excellent thermal conductivity. This means that they can efficiently transfer heat from one area to another, making them ideal for applications where heat exchange is required. In appliances, aluminum coils help in cooling or heating processes by transferring heat between the refrigerant or coolant and the surrounding air or water. Furthermore, aluminum coils offer superior corrosion resistance compared to other metals, making them highly suitable for appliances that come into contact with moisture or other corrosive substances. This property ensures the durability and longevity of the appliances, as the coils are less likely to rust or corrode over time. Moreover, aluminum coils are lightweight, which contributes to the overall efficiency of appliances. The lightweight nature of aluminum reduces the energy required for transportation and installation, making it a more sustainable choice. Additionally, the lightweight coils allow for more compact designs, maximizing space utilization in appliances. Another advantage of aluminum coils is their malleability. They can be easily shaped and formed into different sizes and configurations, allowing for customized designs that suit specific appliance requirements. This flexibility in design enables manufacturers to create efficient heat exchangers that fit into the limited space available in appliances. In summary, aluminum coils are used in the manufacturing of appliances due to their excellent thermal conductivity, corrosion resistance, lightweight nature, and malleability. These properties make them an ideal choice for heat exchangers, which are crucial components in appliances that require efficient cooling or heating processes.

- Q:Can aluminum coils be painted or printed on?

- Yes, aluminum coils can be painted or printed on. Aluminum is a versatile material that can be coated or painted to achieve various finishes and colors. The surface of aluminum coils can be prepared through a process called pre-treatment, which involves cleaning, etching, and applying a primer. This prepares the surface for painting or printing. Painting aluminum coils involves applying a coating system that typically consists of a primer, a color coat, and a topcoat for protection. The paint can be applied using various methods such as spraying, roll coating, or coil coating. Coil coating, in particular, is a commonly used method where the paint is applied to the coil before it is formed into the desired shape. This ensures a uniform and consistent finish. Printing on aluminum coils is also possible using different techniques such as screen printing, digital printing, or lithography. These methods allow for detailed designs, patterns, or even photographs to be printed onto the surface of the aluminum coil. It is important to note that the choice of paint or printing method may depend on the specific requirements of the application, such as durability, weather resistance, or aesthetic preferences. Additionally, proper surface preparation, selection of suitable coatings, and adherence to recommended application guidelines are essential for ensuring a successful and long-lasting paint or print finish on aluminum coils.

- Q:What is the maximum length of aluminum coils?

- The maximum length of aluminum coils can vary depending on factors such as the type and thickness of the aluminum, the manufacturing process, and transportation limitations. Typically, aluminum coils can range from a few hundred feet to several thousand feet in length.

- Q:Are aluminum coils suitable for high-reflective applications?

- Indeed, high-reflective applications are well-suited for aluminum coils. Renowned for its exceptional reflectivity, aluminum boasts a reflectance ratio ranging from 80 to 90%. Consequently, it serves as an impeccable material for endeavors necessitating considerable reflectivity, including lighting fixtures, solar panels, and mirrors. Furthermore, aluminum coils may undergo coating or polishing processes to heighten their reflective attributes. Moreover, aluminum possesses the advantages of being lightweight, corrosion-resistant, and having commendable heat conductivity, rendering it a versatile option for diverse high-reflective applications.

- Q:Why the end of the aluminum coil will have a yellow spot?

- Without coolant processing one, to see if there is no stain, so you can engage in removal of cooling liquid is not interference. Blank surface should have a layer of alumina film processing, heat, such conditions should make the cooling liquid and the alkaline layer friction reaction

- Q:Are there any limitations to the coil weight of aluminum coils?

- Yes, there are limitations to the coil weight of aluminum coils. The coil weight of aluminum coils is primarily limited by the capacity of the equipment used for handling and transporting the coils. Different machinery and materials handling systems have different weight capacities, and exceeding these capacities can lead to safety hazards and damage to the equipment. Additionally, the size and dimensions of the coils can also impact the maximum weight limit. Larger coils tend to have a higher weight limit, as they have a larger surface area to distribute the load. However, there is a practical limit to the weight that can be carried by the machinery and equipment, regardless of the coil size. Moreover, the strength and integrity of the material being used also play a role in determining the coil weight limit. Aluminum is a lightweight material with a high strength-to-weight ratio, which allows for larger coil weights compared to other materials. However, extreme weight can cause deformation or damage to the coil, affecting its quality and usability. It is important to consider these limitations and adhere to the manufacturer's recommendations and industry standards when determining the maximum coil weight. Proper handling, storage, and transportation procedures should be followed to ensure the safety of personnel and the integrity of the aluminum coils.

- Q:What are the thickness tolerances for aluminum coils?

- The thickness tolerances for aluminum coils can vary depending on the specific grade and alloy of aluminum being used. Generally, the tolerance range for aluminum coil thickness is within +/- 0.003 to 0.015 inches (0.076 to 0.381 mm). However, it is important to note that different industries and applications may have their own specific requirements and tolerances. It is recommended to consult the relevant industry standards or specifications to determine the precise thickness tolerances needed for a particular application.

- Q:Can aluminum coils be formed into different shapes?

- Yes, aluminum coils can be formed into different shapes through various processes such as bending, rolling, or stamping.

- Q:Consider the following ionization energies for aluminum:Al(g) → Al+(g) + eI1 = 580 kJ/molAl+(g) → Al2+(g) + eI2 = 1815 kJ/molAl2+(g) → Al3+(g) + eI3 = 2740 kJ/molAl3+(g) → Al4+(g) + eI4 = 11,600 kJ/mol A) Account for the trend in the values of the ionization energies.B) Explain the large increase between I3 and I4.

- aluminum forms an ion by loosing electrons. once an electron is lost, the nucleus attains net positive charge. as a result, the remaining electrons are strongly held by nuclea force of attraction, hence more energy is required to remove them.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

color coated aluminum coil for ACP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords