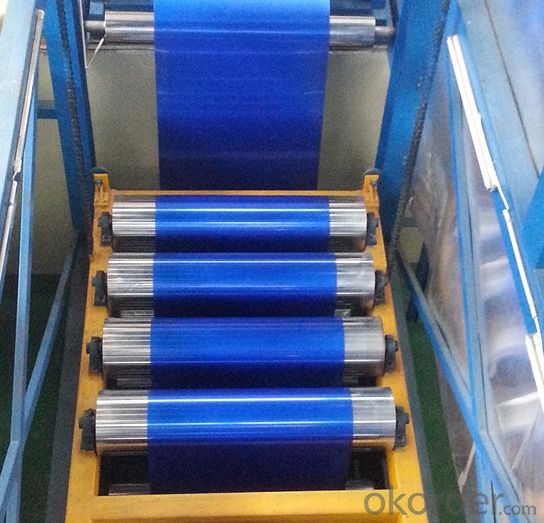

Color Coated Aluminum Coil 3003 H16 H18 for Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

1.Alloy:1,3,5,8xxx

2.Thickness:0.2-12.0mm

3.Width:20-1900mm

4.Alloy:HO/H12/H14/H16/H18/H22/H24/H26/H112

DC or CC, A1050/A1100/A3105/A3003/3104/A5052/A5083/A8011 Aluminum coil for roofing, ceiling,gutter,decoration

Features:

The surface can be plain ,colorful,stucco embossed,diamond embossed.aluminum coil for composite panel used to for building and indsutry, such as roofing sheets, ceilling, transporting,decoration,etc

aluminum coil for composite panel used to for building and indsutry, such as roofing sheets, ceilling, transporting,decoration,etc

The surface can be plain ,colorful,stucco embossed,diamond embossed.

Quality Certification:

According to EN and GB/T standards or as per agreed customer specifications.

Aluminum Coil for Beverage Cans, Food Cans and Closures Specifications

Alloy | Thickness(mm) | Width(mm) | Temper | DC or CC |

1050,1060,1070,1100,1235,1145 | 0.2-4.0 | 20-1500 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC |

4.0-12.0 | 1000-1900 | H111,H112 | DC | |

3003,3004,3105 | 0.2-4.0 | 20-1500 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC |

4.0-12.0 | 1000-1900 | H111,H112 | DC | |

5052,5083,5754,5005 | 0.2-4.0 | 20-1500 | O,H12,H22,H14,H24,H16,H26,H18 | DC |

4.0-12.0 | 1000-1900 | H111,H112 | DC | |

8011 | 0.0065-0.2 | 20-1200 | O,H22 | DC,CC |

FAQ of Color Coated Aluminum Coil 3003 H16 H18 for Composite Panel:

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

- Q:high-quality hi-fi power and amplifiers generate large amounts of heat. to dissipate the heat and prevent damage to the electronic components, heat-radiating metal fins are used. would it be better to make these fins out of iron or aluminum? specific heat capacities for aluminum and iron are 0.89 J/degrees C.g and 0.45 J/degrees C.g, respectively. explain your answer

- Look up heat sinks and find one made of iron. You won't. They are always made of aluminum.

- Q:Are aluminum coils suitable for electrical conductivity?

- Indeed, aluminum coils prove to be suitable for electrical conductivity. With its conductivity rating at approximately 62% of the International Annealed Copper Standard (IACS), aluminum stands as a highly conductive material. Consequently, aluminum coils emerge as an exceptional choice for a variety of electrical applications, encompassing power transmission and distribution, electrical motors, and transformers. Furthermore, aluminum coils present a range of advantages, including their lightweight nature, high resistance to corrosion, and lower cost in comparison to copper coils. Nevertheless, it is crucial to acknowledge that aluminum exhibits a lower conductivity than copper, thus potentially necessitating larger aluminum coils to attain the same level of conductivity as smaller copper coils. In summary, aluminum coils remain a viable and frequently employed option for electrical conductivity.

- Q:Besides replacing all the aluminum wiring.

- Aluminum wire, in and of itself, is not the hazard. You can buy receptacles that are rated for AL/CU Aluminum and copper. If the wire is intact, replace the receptacle with an AL/CU rated receptacle, and be extra careful how much torque you put on the screws that hold the wire down. AN AL/CU rated receptacle costs around $3.50 compares to the cheap $0.59 copper only rated junkers at Home Depot? You do NOT have to replace all the aluminum wiring. In other cases, you can couple AL to CU wire with approved Wire Nuts that are rated for AL/CU. BE EXTRA CAREFUL ABOUT BEND RADIUS AND TORQUE SPECS!

- Q:What are the potential applications of recycled aluminum coils?

- Recycled aluminum coils have various potential applications across several industries. They can be used in the manufacturing of automotive parts, such as body panels, engine components, and heat exchangers. Additionally, they can be utilized in the production of building materials like roofing, gutters, and siding due to their corrosion resistance and durability. Moreover, recycled aluminum coils are suitable for packaging purposes, including beverage cans, food containers, and aerosol cans. Their versatility and sustainability make them an excellent choice for a wide range of applications.

- Q:I need to write as many interesting facts as i can about aluminum for a thing for school, any help?

- Aluminum, Motorcycle engine aluminum radiator made by precise die casting

- Q:Are there any limitations on the powder coating of aluminum coils?

- Yes, there are limitations on the powder coating of aluminum coils. Firstly, the thickness and quality of the aluminum coil can impact the effectiveness of the powder coating process. If the coil is too thin or of low quality, it may not be able to withstand the heat required for the powder coating process, leading to distortion or damage to the coil. Additionally, the surface preparation of the aluminum coil is crucial for successful powder coating. Any contaminants or impurities on the surface, such as oils, dirt, or oxides, can interfere with the adhesion of the powder coating. Proper cleaning and pre-treatment of the surface is necessary to ensure a smooth and durable coating. Furthermore, the size and shape of the aluminum coil may also pose limitations. Complex shapes or intricate designs may be challenging to coat evenly, resulting in variations in coating thickness or coverage. It may require special techniques or equipment to ensure a uniform and consistent coating. Finally, the choice of powder coating material may impact the limitations. Certain powder coatings may not be suitable for use on aluminum coils due to chemical compatibility issues or inadequate adhesion properties. It is important to select a powder coating material specifically designed for use on aluminum substrates. Overall, while powder coating is a popular and effective method for coating aluminum coils, there are limitations that need to be considered. Proper surface preparation, substrate quality, and coating material selection are crucial factors to ensure a successful and durable powder coating finish.

- Q:What is the typical coil diameter for aluminum coils?

- The typical coil diameter for aluminum coils can vary depending on the specific application and industry, but it is generally in the range of 12 to 72 inches.

- Q:Are aluminum coils suitable for beverage can manufacturing?

- Yes, aluminum coils are suitable for beverage can manufacturing.

- Q:Can aluminum coils be used for packaging applications?

- Yes, aluminum coils can be used for packaging applications. Aluminum is a versatile material that offers several beneficial properties for packaging purposes. It is lightweight, corrosion-resistant, non-toxic, and has excellent thermal conductivity. These qualities make aluminum coils ideal for packaging applications, such as food and beverage containers, pharmaceutical packaging, and cosmetic packaging. Additionally, aluminum can be easily formed into different shapes and sizes, allowing for customized packaging solutions. Its durability ensures the protection of the packaged goods, while its recyclability makes it an environmentally friendly choice. Overall, aluminum coils are widely used in packaging applications due to their versatility, performance, and sustainability.

- Q:What are the potential risks of using aluminum coils in specific applications?

- The potential risks of using aluminum coils in specific applications include corrosion, especially in environments with high humidity or acidic conditions. Aluminum coils are also more susceptible to damage and denting compared to other materials. Additionally, aluminum coils may have lower heat transfer capabilities, which could affect the efficiency of certain applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminum Coil 3003 H16 H18 for Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords