Color Coated Aluminium Sheets for Floor Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

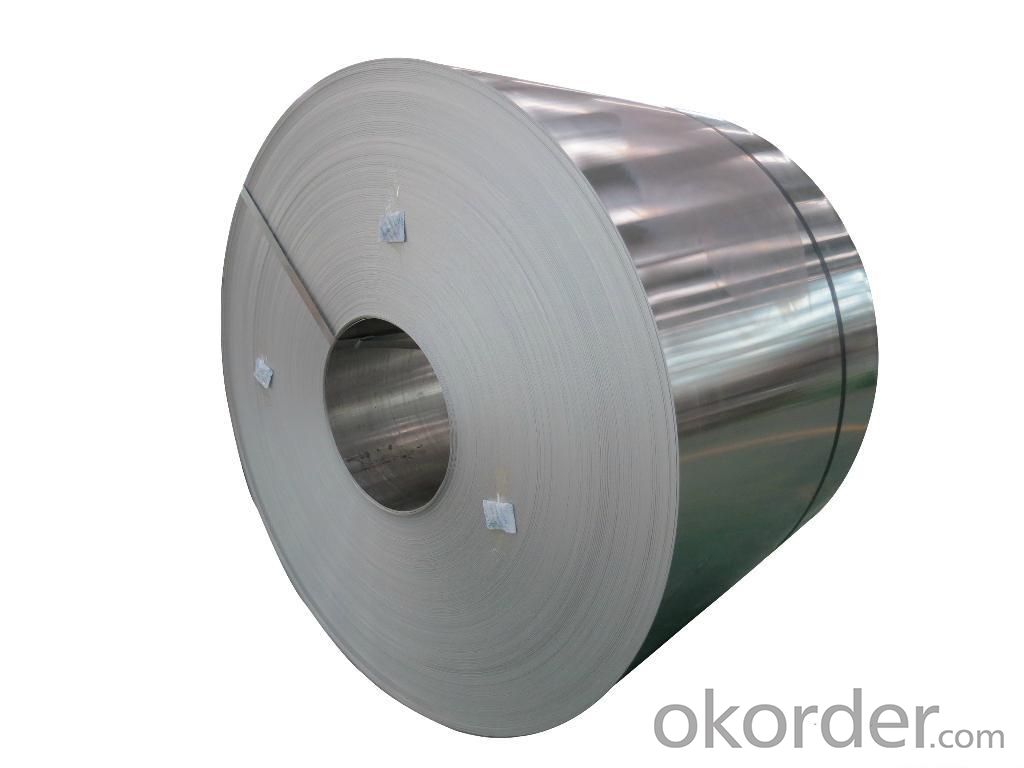

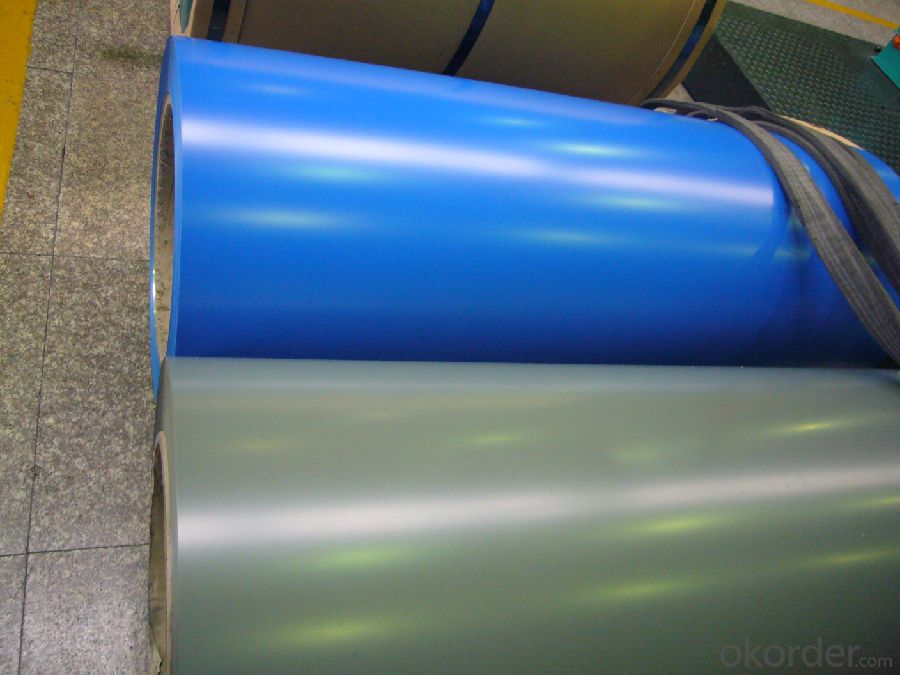

1.Structure of Color Coated Aluminium Sheets for Floor Decoration

Color Coated Aluminium Sheets for Floor Decoration is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Coated Aluminium Sheets for Floor Decoration

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Color Coated Aluminium Sheets for Floor Decoration

4. Product Specification of Color Coated Aluminium Sheets for Floor Decoration

| ALLOY | TEMPER | THICKNESS | WIDTH | WEIGHT |

| AA1050 | H15 | 0.2MM-5MM | 1000MM-1500MM | 3TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:where can I sell aluminum tabs from aluminum cans in Palmdale, Califronia?

- For okorder /

- Q:1100 scope of application of aluminum plate

- 1100 aluminum plate is generally used in utensils, heat sink, caps, printing plates, building materials, heat exchanger components, but also can be used as deep stamping products. It is widely used in various fields ranging from cooking utensils to industrial equipment

- Q:The minimum thickness of aluminum curtain wall is 2, 5mm or 3mm?

- The conventional design of single aluminum plate is up to 2.5 mm, the other I still haven't met,

- Q:Can aluminum sheet withstand heavy loads?

- Indeed, the durability of aluminum sheet is such that it can endure substantial loads. Renowned for its exceptional strength-to-weight ratio, aluminum proves to be an exceptional selection for endeavors necessitating both resilience and load-bearing capacities. Notably prevalent in sectors like aerospace, automotive, construction, and marine, aluminum sheets are frequently employed in scenarios involving weighty burdens. Moreover, the innate corrosion resistance of aluminum further fortifies its capacity to bear heavy loads for extensive durations. Nevertheless, it is crucial to take into account the precise grade and thickness of the aluminum sheet, as diverse alloys and thicknesses yield differing load capacities.

- Q:I have heard that drinking from aluminum cans is bad for our health. However, I have learned that today's 'aluminum' cans are actually more like a plastic can due to all the coatings, etc. Do we really have any risks associated with regular cans?

- Aluminum cans have a thin plastic lining. This lining prevents the leeching of aluminum into the liquid it contains. The big health scare over aluminum was over research done on Alzheimer's disease. Autopsies revealed a higher concentration of aluminum in the brain of some patients with Alzheimer's. It is unknown whether aluminum was a possible culprit, or the diseased tissue for some reason just held onto more aluminum. Further research has not been able to duplicate these results; autopsies of some patients show no increased levels of aluminum. [1], [2], [3], [4] Aluminum toxicity is rare and usually found in patients with renal failure. [5] The amount of aluminum you would be exposed to even if cans were not coated wouldn't cause you any harm.

- Q:Are aluminum sheets suitable for automotive suspension components?

- Yes, aluminum sheets are suitable for automotive suspension components. Aluminum is a lightweight and durable material that offers several advantages for suspension components. Firstly, aluminum sheets are significantly lighter than traditional steel components. This weight reduction can lead to improved fuel efficiency and overall vehicle performance. By reducing the weight of suspension components, the vehicle's handling, acceleration, and braking can be enhanced, resulting in a smoother and more responsive ride. Secondly, aluminum has excellent strength-to-weight ratio, which means it can provide the necessary structural integrity and support for suspension components while still being lightweight. It possesses high tensile strength and stiffness, allowing it to withstand the stresses and forces exerted on suspension components during normal driving conditions. Moreover, aluminum is highly corrosion-resistant, which is beneficial for automotive suspension components that are exposed to various environmental conditions. This corrosion resistance ensures the longevity and durability of the suspension system, reducing the need for frequent repairs or replacements. Additionally, aluminum is easily machinable, allowing for complex and intricate designs that can optimize suspension performance. Its flexibility in shaping and forming enables manufacturers to create suspension components with specific geometries and characteristics to meet the desired performance requirements. In conclusion, aluminum sheets are indeed suitable for automotive suspension components due to their lightweight, high strength-to-weight ratio, corrosion resistance, and machinability. These properties make aluminum a preferred material for suspension components, resulting in improved vehicle performance, fuel efficiency, and overall durability.

- Q:Cooks are warned not to use aluminum cookware when preparing acidic foods. Why?

- tastes like metal use wood if in doubt

- Q:What are the different alloys available for aluminum sheets?

- There are several different alloys available for aluminum sheets, each with its own unique properties and applications. Some of the most common alloys include: 1. 1100: This is a commercially pure aluminum alloy with excellent corrosion resistance, making it suitable for applications where high levels of corrosion resistance are required, such as in marine environments. 2. 3003: Another commercially pure alloy, 3003 offers good formability, high corrosion resistance, and moderate strength. It is commonly used for general sheet metal work, cooking utensils, and chemical equipment. 3. 5052: This alloy is known for its high fatigue strength and excellent corrosion resistance, particularly in saltwater environments. It is often used in marine applications, as well as for aircraft components and fuel tanks. 4. 6061: A heat-treatable alloy, 6061 exhibits good weldability and formability, along with high strength and excellent corrosion resistance. It is commonly used in structural components, such as frames and railings, as well as automotive parts. 5. 7075: This alloy is known for its high strength-to-weight ratio, making it ideal for aerospace applications and high-stress structural components. However, it is less corrosion resistant than other alloys and may require protective coatings in certain environments. These are just a few examples of the alloys available for aluminum sheets. The choice of alloy will depend on the specific requirements of the application, such as strength, corrosion resistance, formability, and cost. It is important to consult with a knowledgeable supplier or engineer to determine the most suitable alloy for your specific needs.

- Q:Can 101 aluminum sheets be used for roofing or siding?

- Indeed, one can utilize 101 aluminum sheets for either roofing or siding purposes. Aluminum, renowned for its robustness, lightweight composition, and ability to resist corrosion, remains a favored material for both roofing and siding applications. Opting for aluminum sheets as a roofing or siding solution guarantees a durable outcome, capable of enduring adverse weather conditions with minimum upkeep. What's more, aluminum sheets are accessible in several thickness options, including 101, thereby providing flexibility to accommodate diverse design and structural requirements.

- Q:Our production needs a large number of plating aluminum plate, consult domestic and imported aluminum plate difference?

- Guangdong Huayuan prosperous is the largest aluminum plate supplier 021-56808701, in Shanghai / Tianjin / Chongqing have logistics and storage, domestic aluminum plating surface coating treatment is less than imports, stamping coating is easy to fall,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminium Sheets for Floor Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords