Color Coated Aluminium Sheet for Building Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Color Coated Aluminium Sheet for Building Decoration

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Color Coated Aluminium Sheet for Building Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminium Sheet for Building Decoration

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

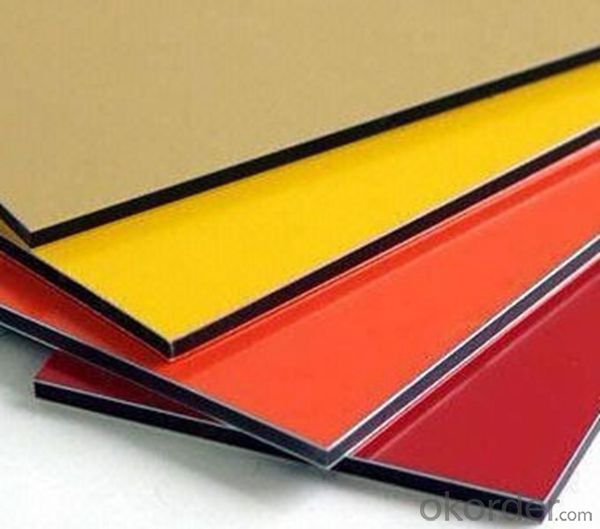

5. Image of Color Coated Aluminium Sheet for Building Decoration

6. Package and shipping of Color Coated Aluminium Sheet for Building Decoration

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q:how much should the current be adjusted when I use pulse aluminum welding machine to weld 0.7 aluminum sheet?

- 60-70A current is enough for 0.7 aluminum sheet,the key poiny is that the thin sheet should be bonded with iron sheet or other assistant cooling device when you weld it, or it will be burned through.

- Q:According to the reactivity of metals, aluminum chloride (AlCl3) will not react with copper (Cu). But I am almost sure that the copper nail I put in the aluminum chloride solution became shiny and lost its copper lust. Why did this reaction happen?

- Well done on noting unexpected observations and following up. Your copper is coated with a dull coating of copper oxide. It became shiny because aluminium salts are acidic in water and the acidity dissolves the coating to form a copper salt and leaving the shiny copper. CuO + 2H3O+ ---- Cu2+ + 3H2O The reaction to form the acidity, a hydrated hydrogen ion H+(H2O) or H3O+ is fairly complex. If aluminium chloride is dissolved in a large amount of water the solution is acidic, but this has nothing to do with formation of hydrochloric acid. The solution contains hydrated aluminium ions and chloride ions: AlCl3(s) + aq → [Al(H2O)6]3+(aq) + 3Cl -(aq) The hexaqua complex ion behaves exactly like ions of similar type formed from transition metals; the small, highly charged metal ion polarises (withdraws electron density from) the water molecules that are attached to the aluminium ion through dative covalent bonds. This makes the hydrogen atoms d+ and susceptible to attack from solvent water, which is acting as a base. The complex ion is deprotonated, causing the solution to be acidic from the formation of hydroxonium ions H3O+: [Al(H2O)6]3+(aq) + H2O(l) → [Al(H2O)5OH]2+(aq) + H3O+(aq)

- Q:Are there any specific storage requirements for 101 aluminum sheets?

- Yes, there are specific storage requirements for 101 aluminum sheets. It is important to store them in a dry, clean, and well-ventilated area to prevent any moisture damage or contamination. Additionally, they should be stored in a horizontal position to avoid warping or bending.

- Q:Can aluminum sheets be used for elevator interiors?

- Indeed, elevator interiors can certainly be constructed using aluminum sheets. Aluminum has gained significant popularity as a material of choice for elevator interiors due to its multitude of advantageous qualities. Its lightweight nature, durability, and resistance to corrosion render it highly suitable for long-term utilization in elevator applications. With ease, aluminum sheets can be skillfully fabricated and shaped to perfectly fit the dimensions and design specifications of elevator interiors. Furthermore, aluminum can be enhanced with various types of coatings or finishes, such as anodizing or powder coating, to not only augment its aesthetic appeal but also provide additional protection. Overall, aluminum sheets represent a practical and widely utilized option for elevator interiors within the industry.

- Q:I wish to purchase an 8' step ladder as well as a medium length extension ladder. What are the pros and cons of aluminum vs. fiberglass?

- Plus they are heavier, will take a truck with at least a V6. Aluminum on the other hand is lighter, does not look as good, has less maintenance, can take more abuse than fiberglass. But an aluminum boat is not as wide as a fiberglass boat, that is my biggest complaint. The width makes a big difference, like women's hips !! wider the better !! Look at a 17' boat, world of difference in the 1'. Good luck be careful,

- Q:Can aluminum sheets be polished for a mirror-like finish?

- Yes, aluminum sheets can be polished to achieve a mirror-like finish. Aluminum is a relatively soft metal and can be easily polished to a high shine. The process typically involves sanding the surface with progressively finer grits of sandpaper, followed by buffing with polishing compounds and a soft cloth or a polishing wheel. The goal is to remove any scratches or imperfections on the surface and create a smooth, reflective finish. With the right techniques and tools, aluminum sheets can be polished to a mirror-like shine, making them suitable for various applications such as decorative purposes, automotive parts, or reflective surfaces in optical devices.

- Q:Is aluminium plate the same as aluminium alloy?

- Oh, No. aluminum contains only aluminum, and there are some other metals besides aluminium.

- Q:Are 101 aluminum sheets suitable for interior design or architectural applications?

- Yes, 101 aluminum sheets are suitable for interior design or architectural applications. They are commonly used due to their lightweight nature, durability, and corrosion resistance. Additionally, they can be easily formed into various shapes and sizes, making them versatile for different design purposes.

- Q:How to carry out drawing process in aluminium plate

- The process of repeated scraping is an essential step in the production and processing, and we can not forget. The second is in the process of the film, to make the drawing processing after more shiny, look more beautiful, the film is the key technology in the field of production and processing. Should be careful, careful, can not be careless, such a careful and responsible work attitude, for drawing aluminum plate each place to do the details of the treatment, so that the filaments will be dense and bright.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminium Sheet for Building Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords