Color Coated Aluminium Embossed Coil Foil Roll for Food 2015 China Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

(4),Color coating steel is cold rolled steel sheet and galvanized steel substrate, after surface pretreatment (degreasing, cleaning, chemical conversion treatment), with the method of continuous coated with paint (roller coating method), after baking and cooling and manufactured products.

3. Feature of Aluminum

1100-H14-DIAMOND EMBOSSED ALUMINUM SHEET

Thickness:1.2mm---4mm,

width:1000mm---1500mm

Product code: 618 a - 33 y titanium matte aluminum plate

Technical parameters

Aluminum alloy/material: 1100

Tensile strength N/was: 115-125

The yield strength of N/was: 150-150

Elongation % : 3 or more

Rainbow degrees: no

Process: light oxidation process

Product description: surface "colored metal silken face" as the main characteristics of the product, completely metal texture, color variety, products can be mild tensile and bending.

Product use: can be used to directly shape stamping, screen printing, thermal transfer two composite process, etc.Used in architectural decoration, household appliances, switch panel, auto parts, lamps lighting, electronic hardware and other industries.

Supply scope of coil or sheet

Mm thickness specification: 0.4 1

Maximum width mm: 1250

The tolerance range

Mm thickness: 0.02 mm

The width of the mm: 2 -

Mm length: 2 -

Actual weight kg: plus or minus 2

Protective film

Protective film on the surface of the aluminum quality assurance period for six months, aluminum is kept dry and ventilated, avoid heat and direct sunlight.If the aluminium material stored in high temperature or direct sunlight can cause protective film, or unable to tear in addition to wait for a phenomenon.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

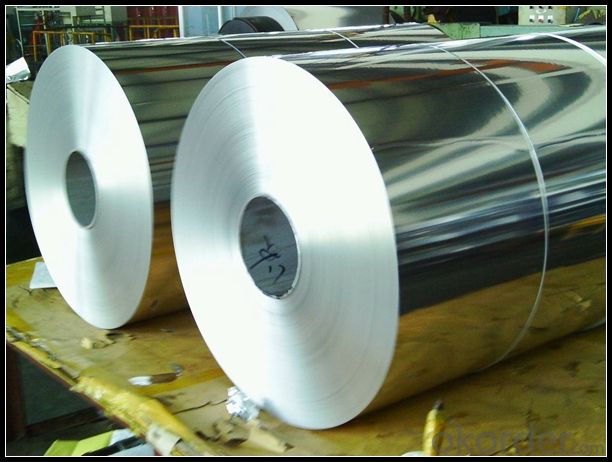

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q:Can aluminum sheet be painted?

- Certainly, painting aluminum sheet is possible. However, it is crucial to adequately prepare the surface beforehand to guarantee strong paint adhesion and long-lasting results. Typically, this involves thoroughly cleaning the aluminum sheet to eliminate any dirt, grease, or oxidation. Subsequently, a primer is applied to enhance adhesion. Once the primer has dried, you can proceed with applying your desired paint. For optimal outcomes, it is recommended to select a high-quality paint suitable for metal surfaces. Moreover, if the aluminum sheet will be exposed to outdoor conditions, it is advisable to utilize a paint specifically designed for exterior use. This will ensure protection against weathering and corrosion.

- Q:Can aluminum sheets be used for architectural facades?

- Yes, aluminum sheets can be used for architectural facades. Aluminum is a lightweight and durable material that is commonly used in construction due to its corrosion resistance and versatility. It can be easily shaped, cut, and formed into various sizes and designs, making it suitable for creating aesthetically pleasing architectural facades. Additionally, aluminum sheets offer excellent weathering properties, low maintenance requirements, and can be finished with different coatings to enhance their appearance and protection against environmental elements.

- Q:the amp setting when welding aluminum tig? and what color should the electrode feeder be bronze or chrome grey? u know the one u use with your hands

- Best electrodes to use for Aluminum welding is 1.5% lanthanum oxide (gold color code.). 2% zirconia (brown) or 2% thorium oxide (red) can also be used. Note that zirconia-doped electrodes should never be used for DC welding. A lot of welders like to quote offhand the rule 1 amp for every 0.001 inch of thickness. This applies to steel, stainless, and nickel alloys only. Due to the lower melting point, lower specific heat capacity, and higher thermal conductivity of of Al, this rule should NOT be used for Al! I recommend welding a test piece first with the same joint configuration and thickness of the part you intend to weld. Note that fillet welds require more current than butt welds or edge welds. Start out by using 2/3 amp per 0.001 of thickness, in other words, reduce the current of the above rule by about 30-40% . Make 3 test weld, then check to see if there's any visible penetration on the other side. If you don't see any through-pentration at all, increase the current by about 10-20 amps and test again.

- Q:Can aluminum sheets be welded or joined together?

- Yes, aluminum sheets can be welded or joined together. Aluminum is a highly weldable material and can be joined using various welding techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and laser welding. These techniques utilize heat to melt the aluminum sheets and create a strong bond. Additionally, aluminum sheets can also be joined using mechanical fasteners like screws, rivets, or adhesive bonding. The choice of welding or joining method depends on the specific application and desired outcome.

- Q:Are aluminum sheets suitable for cladding?

- Yes, aluminum sheets are suitable for cladding purposes. Aluminum is a popular choice for cladding due to its numerous advantages. Firstly, it is lightweight, making it easier to handle and install. This reduces the overall weight of the cladding system and minimizes structural load. Secondly, aluminum is highly durable and resistant to corrosion, making it suitable for both interior and exterior applications. It is also weather-resistant, ensuring that the cladding remains in good condition even in harsh climates. Additionally, aluminum is a highly versatile material that can be easily shaped and fabricated, allowing for a variety of design options. It can be painted or coated with various finishes to enhance its appearance and provide additional protection. Moreover, aluminum cladding is low maintenance, as it does not require frequent cleaning or painting. Overall, aluminum sheets are an excellent choice for cladding due to their lightweight, durability, versatility, and low maintenance requirements.

- Q:I am doing a report on machining aluminum and characteristics of aluminum and can not find what the 6061 stock stands for. Looked all over library, internet, etc.

- Aluminium alloy 6061 is one of the most extensively used of the 6000 series aluminium alloys. It is a versatile heat treatable extruded alloy with medium to high strength capabilities. Composition Table 1. Typical composition of aluminium alloy 6061 Component Amount (wt.%) Aluminium Balance Magnesium 0.8-1.2 Silicon 0.4 – 0.8 Iron Max. 0.7 Copper 0.15-0.40 Zinc Max. 0.25 Titanium Max. 0.15 Manganese Max. 0.15 Chromium 0.04-0.35 Others 0.05 Key Properties Typical properties of aluminium alloy 6061 include: · Medium to high strength · Good toughness · Good surface finish · Excellent corrosion resistance to atmospheric conditions · Good corrosion resistance to sea water · Can be anodized · Good weldability and brazability · Good workability · Widely available Note: Property data is provided below, but should be used a guide only. As data may vary between manufacturers, you should consult your supplier for more exact figures. Physical Properties Density: 2.7 g/cm3 Melting Point: Approx 580°C Modulus of Elasticity: 70-80 GPa Poissons Ratio: 0.33 need any more info.

- Q:Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable metal, which means it can be easily shaped and bent without fracturing or breaking. However, the degree of bendability may vary based on the thickness and alloy composition of the aluminum sheet.

- Q:Can aluminum sheets be used for electrical wiring?

- Electrical wiring cannot utilize aluminum sheets. Although aluminum boasts good conductivity, its high electrical resistance renders it unsuitable for such purposes. Copper, on the other hand, is the preferred material for electrical wiring due to its low resistance and superior efficiency in conducting electricity. Moreover, aluminum is susceptible to oxidation, which may result in inadequate conductivity and potential fire risks. Copper wires, on the contrary, are meticulously crafted and produced to comply with electrical safety standards, guaranteeing dependable and secure electrical connections.

- Q:What are the different methods of forming aluminum sheet?

- Aluminum sheet can be formed using various methods, each with its own advantages and limitations. 1) Rolling is the most commonly used method for manufacturing aluminum sheet. It involves passing aluminum ingots through rolling mills, gradually reducing the thickness until the desired sheet thickness is achieved. Rolling is highly versatile, allowing for precise thicknesses and a wide range of sizes. 2) Extrusion involves forcing a heated aluminum billet through a die to create a continuous sheet. This method is often used to produce sheets with complex cross-sectional shapes and consistent thickness. It is ideal for creating aluminum sheets with consistent patterns or textures. 3) Casting entails pouring molten aluminum into a mold and allowing it to solidify. It is commonly used for producing large aluminum sheets with irregular shapes or intricate designs. However, the thickness of cast aluminum sheets may not be as consistent as those created through rolling or extrusion. 4) Stretch forming involves clamping a sheet of aluminum around its edges and stretching it over a die to achieve the desired shape. This method is commonly used for producing curved or contoured aluminum sheets, such as those used in automotive or aerospace applications. 5) Spinning utilizes a rotating disk or mandrel pressed against a sheet of aluminum to shape it into the desired form. This method is frequently employed to create cylindrical or conical aluminum sheets, like those seen in lighting fixtures or cookware. 6) Deep drawing involves placing a flat sheet of aluminum into a die and using a punch to force the metal into the desired shape. It is commonly used for producing aluminum sheets with deep, cup-like shapes, such as those found in beverage cans or automotive parts. Ultimately, the choice of method for forming aluminum sheet depends on factors such as the desired shape, thickness, and complexity of the final product, as well as production volume and cost considerations.

- Q:How do aluminum sheets perform in terms of thermal insulation?

- Aluminum sheets have poor thermal insulation properties. They conduct heat very well, which means they are not effective in preventing heat transfer between different areas or maintaining a consistent temperature.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminium Embossed Coil Foil Roll for Food 2015 China Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords