Color Coated Aluminium Coils Polyester Coating AA3004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

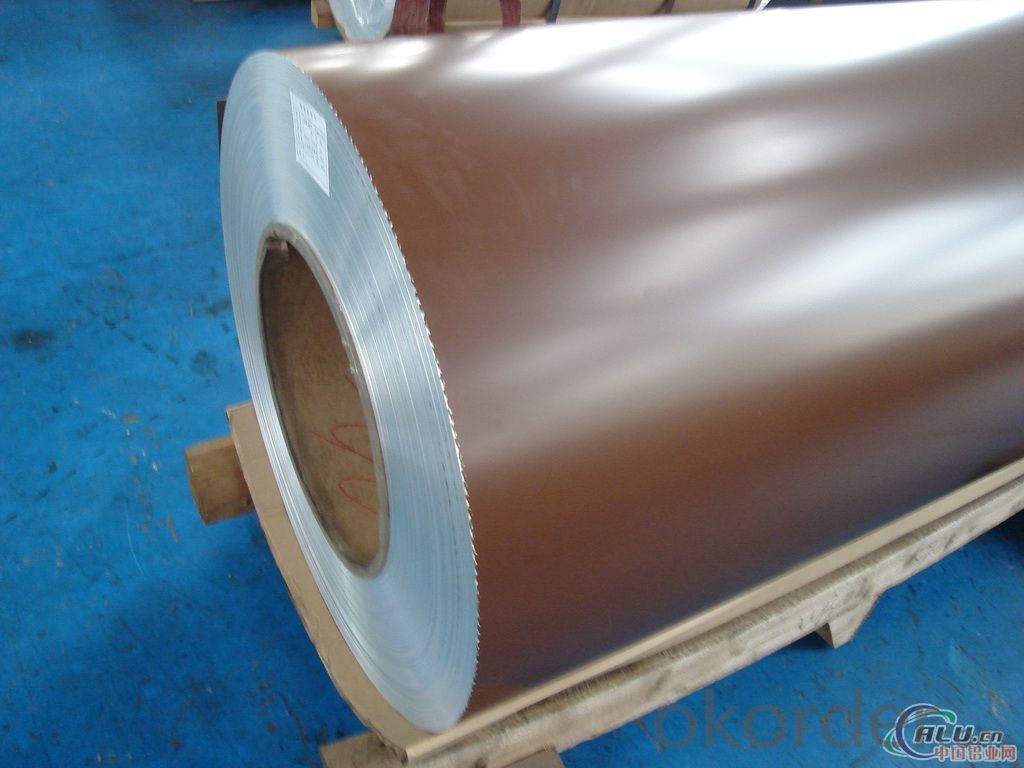

1.Structure of Color Coated Aluminium Coils

PE Coated aluminium coils are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Color Coated Aluminium Coils

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2mm-3mm | 1200MM-1800MM | Min 5 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:Can aluminum sheets be used for automotive body panels?

- Certainly, automotive body panels can indeed utilize aluminum sheets. In reality, the automotive industry is progressively incorporating aluminum due to its lightweight attributes and remarkable strength-to-weight ratio. By employing aluminum sheets for body panels, the overall weight of the vehicle is diminished, thereby enhancing fuel efficiency and performance. Moreover, aluminum exhibits exceptional resistance to corrosion, rendering it an enduring selection for automotive purposes. The use of aluminum sheets for automotive body panels has gained considerable popularity, particularly in the manufacturing of electric vehicles, as their lightweight structure optimizes the vehicle's range.

- Q:Can aluminum sheets be bent or formed?

- Yes, aluminum sheets can be bent or formed due to their malleability and ductility.

- Q:Are aluminum sheets suitable for food-grade applications?

- Indeed, food-grade applications can utilize aluminum sheets. Due to its exceptional attributes, aluminum is extensively employed in the food industry. It is known for being non-toxic, resistant to corrosion, and possessing a high level of thermal conductivity. Consequently, it proves to be a fitting option for both food processing and packaging. Not only can aluminum sheets be utilized in the creation of food-grade containers, trays, and packaging materials, but they are also commonly employed in cooking utensils. For instance, baking sheets and foil made from aluminum are safe to use when in direct contact with food. Moreover, aluminum sheets are easily cleaned and sanitized, thereby making them a hygienic choice for food-grade applications.

- Q:Are the aluminum sheets suitable for manufacturing heat exchangers?

- Yes, aluminum sheets are suitable for manufacturing heat exchangers. Aluminum is a lightweight and highly conductive material, making it an ideal choice for heat transfer applications. Its excellent thermal conductivity allows for efficient heat transfer, resulting in effective cooling or heating processes. Additionally, aluminum is corrosion-resistant, which is crucial for heat exchangers that come in contact with various fluids. The malleability and formability of aluminum sheets also make them easy to shape into the required designs for heat exchanger components. Overall, aluminum sheets offer several advantages for manufacturing heat exchangers, making them a suitable choice for this application.

- Q:How do you prevent surface marring of aluminum sheets during handling?

- To prevent surface marring of aluminum sheets during handling, there are several steps you can take: 1. Use clean gloves or finger cots: When handling aluminum sheets, it is important to avoid direct contact with bare hands as they may contain oils, dirt, or other contaminants that can leave marks on the surface. Wearing clean gloves or finger cots can provide a barrier and prevent any transfer of substances onto the sheets. 2. Use protective packaging: Prior to handling, consider using protective packaging such as foam or plastic sheets to cover the surface of the aluminum sheets. This will provide an additional layer of protection against scratches or abrasions during transportation or storage. 3. Implement proper storage and handling techniques: Store aluminum sheets in a clean and dry environment, away from any abrasive materials or surfaces. When moving or handling the sheets, ensure that they are lifted or supported evenly to avoid any bending or distortion that may lead to surface marring. Using appropriate lifting equipment, such as suction cups or clamps, can help distribute the weight evenly and minimize the risk of damage. 4. Clean the surface regularly: Regularly clean the aluminum sheets using a mild detergent or aluminum-specific cleaning solution. This will help remove any dirt, grime, or other substances that could potentially cause surface marring. Be sure to use soft, non-abrasive cleaning tools such as microfiber cloths or sponges to avoid scratching the surface. 5. Implement quality control measures: Establishing quality control measures during the handling process can help identify any potential sources of surface marring. Regular inspections should be conducted to check for any signs of damage or defects. Implementing proper training for employees involved in the handling process can also help minimize the risk of surface marring. By following these preventive measures, you can significantly reduce the chances of surface marring on aluminum sheets during handling, ensuring their pristine condition and quality.

- Q:What is the typical cost-effectiveness of aluminum sheets compared to other materials?

- Aluminum sheets are generally considered to be cost-effective compared to other materials. This is primarily due to their abundance, lightweight nature, and recyclability, which reduces production costs. Additionally, aluminum sheets offer a high strength-to-weight ratio, corrosion resistance, and durability, making them a popular choice across various industries. However, specific cost-effectiveness may vary depending on factors such as market demand, sheet thickness, and finishing requirements.

- Q:Can aluminum sheets be used for heat exchanger fins?

- Yes, aluminum sheets can be used for heat exchanger fins. Aluminum is a commonly used material for heat exchanger fins due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion.

- Q:Are aluminum sheets suitable for use in electrical applications?

- Yes, aluminum sheets are suitable for use in electrical applications. Aluminum has excellent conductivity and is lightweight, making it an ideal choice for electrical conductors, wiring, and components. Additionally, aluminum sheets offer good thermal conductivity and corrosion resistance, making them reliable and durable in various electrical environments.

- Q:Can the aluminum sheets be used for solar panel frames?

- Yes, aluminum sheets can be used for solar panel frames. Aluminum is a popular choice for solar panel frames due to its lightweight yet sturdy nature. It is corrosion-resistant, which helps protect the frames from environmental factors like rain, humidity, and UV rays. Additionally, aluminum is easily recyclable, making it an environmentally friendly option for solar panel frames. The versatility and durability of aluminum sheets make them a suitable choice for supporting and protecting solar panels, ensuring their longevity and efficient performance.

- Q:How do you prevent warping of aluminum sheets during bending?

- One way to prevent warping of aluminum sheets during bending is by using proper techniques and tools. This includes using the correct bending radius, ensuring even distribution of pressure along the sheet, and employing a suitable clamping method to hold the sheet in place during the bending process. Additionally, preheating the aluminum sheet can help to reduce the likelihood of warping.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminium Coils Polyester Coating AA3004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords