Color Coated Aluminium Coils for Windows Polyester Color

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Color Coated for Windows Description

PE Coated aluminium coils are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

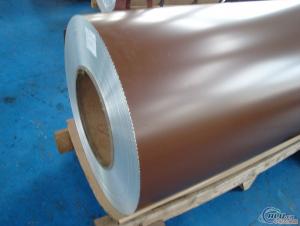

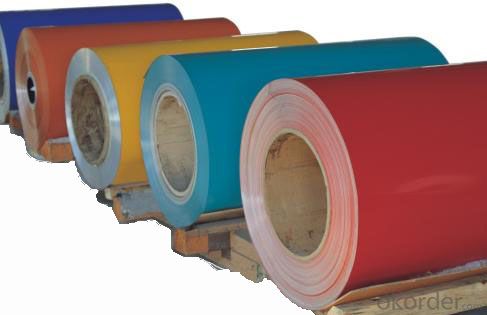

3. Image

4. Products Specification

| Alloy | Paints | Coating Thickness | Period | Final Usage |

| AA3003 | PE | 22-25 MICRONS | 10-15 YEARS | WINDOWS |

5.FAQ

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:Can aluminum coils be used in electrical conductors?

- Yes, aluminum coils can be used in electrical conductors. Aluminum is a good conductor of electricity and is commonly used in various electrical applications, including wiring, power transmission, and motor windings.

- Q:Can aluminum coils be used for solar panel applications?

- Yes, aluminum coils can be used for solar panel applications. They are often utilized as the base material for solar panels due to their lightweight, corrosion-resistant, and durable properties. Additionally, aluminum coils offer good thermal conductivity, enabling efficient heat dissipation in solar panels.

- Q:Can aluminum coil 3003H24 replace 3A21H14?

- It is ok in some way as both of them are alumal. The hardness of 3003H24 is similar to that of 3A21H14 after hardening without annealing. Both have good corrosion resistance, plasticity and bad machinability. They cannot be used as load bearing parts even though small load is ok. They cannot be anodized.

- Q:Can aluminum coils be used in the production of aluminum louvers?

- Yes, aluminum coils can be used in the production of aluminum louvers. Aluminum coils are a common raw material used in various industries, including the manufacturing of louvers. Aluminum coils are typically processed and formed into the shape and design required for louvers, providing the necessary strength and durability. The use of aluminum coils also allows for flexibility in design and customization of louvers to meet specific requirements. Additionally, aluminum is a lightweight and corrosion-resistant material, making it suitable for louvers that may be exposed to outdoor conditions. Overall, aluminum coils are widely used in the production of aluminum louvers due to their numerous advantages and suitability for this application.

- Q:and alsoHow many grams of the decay product will have formed after 8 days go by?The decay product is the new isotope created as a result of the positron decay of aluminum-24.In class my teacher didn't explain this completely but there's a question on the homework that me and even my mom (another teacher) can't find the answer to.

- so it 6000/ (2*8*24*60*60) 0.00434027778 grams have you heard of the internet an unless your mom is a chem teacher it doesnt mean much

- Q:What are the potential applications of embossed aluminum coils?

- Embossed aluminum coils have a wide range of potential applications due to their unique properties and versatility. Some of the potential applications of embossed aluminum coils include: 1. Decorative purposes: Embossed aluminum coils are commonly used in interior and exterior architectural design applications. They can be used for wall cladding, ceiling panels, decorative facades, and other decorative elements. The embossed patterns on the coils add a visually appealing texture and depth to the surfaces, enhancing the overall aesthetic appeal of the space. 2. Packaging industry: Embossed aluminum coils are widely used in the packaging industry. They can be used for manufacturing packaging materials such as cans, boxes, lids, and closures. The embossed patterns on the coils not only enhance the visual appeal of the packaging but also provide additional strength and rigidity to the structure, making it more durable and resistant to damage. 3. Heat transfer applications: Embossed aluminum coils are also used in heat transfer applications. The embossed patterns on the coils create turbulence in the fluid flow, increasing the heat transfer efficiency. This makes them suitable for use in heat exchangers, evaporators, condensers, and other heat transfer equipment. 4. Automotive industry: Embossed aluminum coils find applications in the automotive industry. They are used in the manufacturing of car body panels, trims, and decorative elements. The embossed patterns on the coils can provide a unique and stylish appearance to the vehicles, making them stand out in the crowd. 5. Electrical industry: Embossed aluminum coils are commonly used in the electrical industry for various applications. They can be used for manufacturing electrical enclosures, switchboards, and control panels. The embossed patterns on the coils improve the structural integrity and provide better protection against external factors such as moisture, dust, and corrosion. 6. Furniture industry: Embossed aluminum coils are also used in the furniture industry. They can be used for manufacturing furniture components such as table tops, cabinet doors, and decorative trims. The embossed patterns on the coils add a touch of elegance and sophistication to the furniture, making it visually appealing. Overall, embossed aluminum coils have a wide range of potential applications in various industries, including architecture, packaging, heat transfer, automotive, electrical, and furniture. Their unique properties and versatility make them a preferred choice for many applications where aesthetics, strength, and durability are important.

- Q:Can aluminum coils be customized in terms of thickness?

- Yes, aluminum coils can be customized in terms of thickness. The thickness of aluminum coils can be adjusted according to the specific requirements of a particular application. This customization is achieved through a process called aluminum coil slitting, where the original coil is cut into narrower coils of desired thickness. This allows for flexibility in meeting various needs and specifications of different industries.

- Q:Are there any specific guidelines for the handling of aluminum coils?

- There exist specific guidelines for the handling of aluminum coils, with several key points to consider: 1. Appropriate lifting techniques: To handle aluminum coils, it is crucial to utilize suitable lifting equipment such as cranes or forklifts. These tools must possess the capacity to handle the weight of the coils in order to prevent accidents or damage. 2. Usage of protective gear: Workers must wear personal protective equipment (PPE) like gloves and safety goggles to safeguard themselves against sharp edges or potential injuries during handling. 3. Secure packaging: Aluminum coils must be stored or transported in secure packaging to prevent damage. This can be accomplished by employing suitable pallets, straps, or protective covers to ensure that the coils are held in place and protected against external factors like moisture or impact. 4. Proper stacking: When storing or transporting aluminum coils, it is vital to stack them in a manner that guarantees stability and prevents them from falling or causing accidents. The coils should be stacked evenly and securely, with adequate support and spacing between each stack to avoid deformation or damage. 5. Avoidance of contact with corrosive materials: Aluminum coils should not come into contact with corrosive materials such as acids or alkalis, as they can cause damage or corrosion to the metal. It is important to store aluminum coils in a clean and dry environment to preserve their quality. 6. Gentle handling: Aluminum coils are prone to scratches, dents, and other forms of damage, thus they should be handled with care to avoid these issues. Dragging or sliding the coils during handling should be avoided, and they should be placed gently to prevent any potential damage. 7. Training and supervision: Workers involved in the handling of aluminum coils should receive adequate training and supervision to ensure adherence to the specific guidelines and safety procedures. Regular training sessions can help refresh their knowledge and reinforce safe handling practices. By adhering to these guidelines, the proper handling of aluminum coils can be ensured, thereby reducing the risk of accidents, damage, or loss of quality.

- Q:Can aluminum coils be used in high-temperature applications?

- No, aluminum coils are not suitable for high-temperature applications as they have a low melting point and tend to lose their structural integrity at elevated temperatures.

- Q:Are aluminum coils available in different colors?

- Yes, aluminum coils are available in different colors. The process of coloring aluminum coils involves coating the surface with a durable finish that can be in various colors. This coating is typically achieved through a process called coil coating, where the aluminum coil is cleaned, pre-treated, and then coated with a layer of paint or other colored material. This allows for a wide range of colors to be applied to the aluminum coils, providing flexibility in design and aesthetic options for various applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminium Coils for Windows Polyester Color

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords