Color Coated Aluminium Coils for Window Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

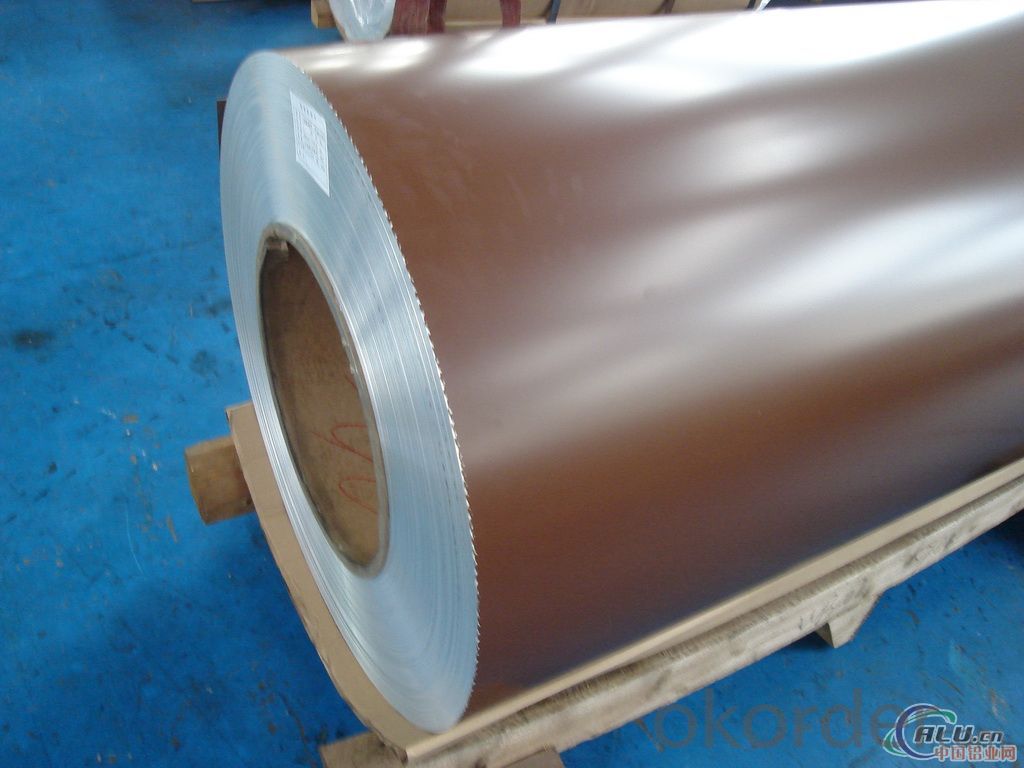

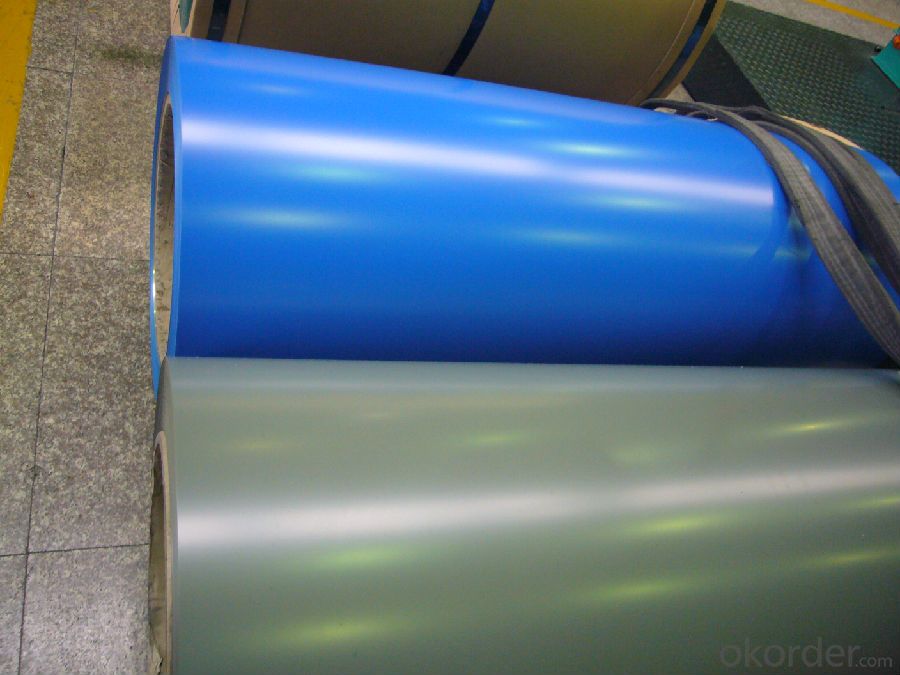

1.Structure of Color Coated Aluminium Coils for Window Decoration

Color Coated Aluminium Coils for Window Decoration is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Coated Aluminium Coils for Window Decoration

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Color Coated Aluminium Coils for Window Decoration

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:Can aluminum sheets be bent without cracking?

- Yes, aluminum sheets can be bent without cracking. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and formed without breaking. However, the ability to bend aluminum sheets without cracking depends on several factors such as the thickness of the sheet, the type and grade of aluminum used, and the specific bending technique employed. It is important to use proper tools and techniques when bending aluminum to ensure that it remains intact and free from cracks.

- Q:Can 101 aluminum sheets be used in the production of sporting goods?

- Yes, 101 aluminum sheets can be used in the production of sporting goods. Aluminum is a versatile material that offers several benefits for sporting equipment. It is lightweight, which is crucial for many sports equipment like bicycles, tennis rackets, and baseball bats, as it allows for easier handling and maneuverability. Additionally, aluminum is corrosion-resistant, ensuring the longevity of the sporting goods even when exposed to various weather conditions. It also provides excellent strength-to-weight ratio, making it suitable for high-performance equipment that requires durability without adding unnecessary weight. Therefore, 101 aluminum sheets can be a viable choice for manufacturing various sporting goods, providing the desired properties needed for performance, longevity, and user experience.

- Q:What are the safety precautions when working with aluminum sheet?

- To ensure your well-being and reduce the likelihood of accidents or injuries, it is essential to observe specific safety measures when working with aluminum sheet. Consider the following precautions: 1. Personal Protective Equipment (PPE): Safeguard yourself against potential hazards by wearing appropriate PPE, such as safety glasses, gloves, and a long-sleeved shirt. Aluminum shavings can cause injuries if they come into contact with your skin due to their sharpness. 2. Ventilation: Work in a well-ventilated area or employ local exhaust ventilation systems to prevent the accumulation of fumes and dust. Inhalation of large quantities of aluminum dust or fumes can be harmful. 3. Fire safety: As aluminum is highly flammable, it is crucial to keep flammable materials away from the work area. Ensure you have a fire extinguisher readily available and know how to use it in case of emergencies. 4. Tool safety: Verify that all tools and equipment used for cutting, bending, or shaping aluminum are in good working condition. Accidents are more likely to occur with dull or damaged tools. Follow proper tool handling techniques and avoid using excessive force to minimize the risk of injuries. 5. Proper handling: When moving or lifting aluminum sheets, employ correct lifting techniques and seek assistance if needed. Improper handling can lead to strains or muscle injuries due to the weight of the sheets. 6. Electrical safety: If electrical tools or equipment are utilized, make sure they are properly grounded and in good working order. Avoid using damaged or frayed cords and keep them away from moisture sources. 7. Storage: Store aluminum sheets in a designated area, away from heat sources or flammable materials. Stack and secure the sheets properly to prevent accidents caused by falling objects. 8. First Aid: Keep a first aid kit readily available to address minor injuries. Familiarize yourself with appropriate first aid procedures for cuts, burns, or any other potential injuries that may occur while working with aluminum sheets. By adhering to these safety precautions, you can establish a safe working environment and minimize the risks associated with handling aluminum sheets. Remember to prioritize your safety and the safety of those around you at all times.

- Q:My professor gave us the following:1roll of Reynonlds Wrap Heavy Duty Aluminum18.0 in wide, 500.0 ft long and 0.94mil thickThe cost $48.98and I'm not sure how to figure it out

- length * width * thickness = volume (with some unit conversions) Mass = volume * density (look up the density of aluminum) convert mass to moles. convert moles to atoms Divide the cost by the number of Al atoms.

- Q:Are aluminum sheets suitable for architectural roofing?

- Indeed, architectural roofing can indeed be accomplished with aluminum sheets. Aluminum, being a lightweight substance, is resistant to corrosion, which renders it an optimal selection for roofing purposes. Moreover, it is highly durable and capable of withstanding severe weather conditions, such as extreme temperatures, UV radiation, and strong winds. To add to its appeal, aluminum sheets are accessible in various colors and finishes, granting flexibility in terms of design and aesthetics. Furthermore, aluminum proves to be an environmentally friendly and sustainable material as it can be recycled perpetually without compromising its properties. In summary, aluminum sheets exhibit outstanding performance and versatility, thus making them a favored option for architectural roofing.

- Q:Can aluminum sheet be used for food packaging?

- Yes, aluminum sheet can be used for food packaging.

- Q:There seems to be a load of buzz out there regarding the use of aluminum pots and pans. They apparently may cause Alzheimer’s or bone degeneration in women. I have some cast iron pans that I use when ever possible but they are not always practical. I’d like some of you kitchen pros to give me some sound advice regard the use of aluminum in the home kitchen. I know they are used in food service organizations.... I look forward to some informative replys.Thanks in advance.

- each thing you do in any given day would reason some style of maximum cancers. you may could be residing in a bubble to not be uncovered. of direction, the bubble could be produced from some style of plastic which of direction would desire to divulge you to 3 strand of maximum cancers besides.

- Q:Can aluminum sheets be used for aircraft manufacturing?

- Yes, aluminum sheets are commonly used in aircraft manufacturing due to their lightweight yet strong properties, making them ideal for constructing various components such as wings, fuselage, and structural parts. Aluminum's excellent corrosion resistance and high strength-to-weight ratio make it a preferred choice in the aerospace industry.

- Q:What is the density of the 2A12 aluminum plate?

- 2.75 density. Shenzhen dexincheng metal plate is sold. Specifications are all complete.

- Q:The which temperature the aluminum evaporates in vacuum?

- Aluminum boils at 2519 °C (4566 °F) at normal pressure. In a vacuum, it might boil (a little) at 808 °C, but actually this is better known as subliming.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminium Coils for Window Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords