Color Coated Aluminium Coils for Inner Decoration Ceilling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

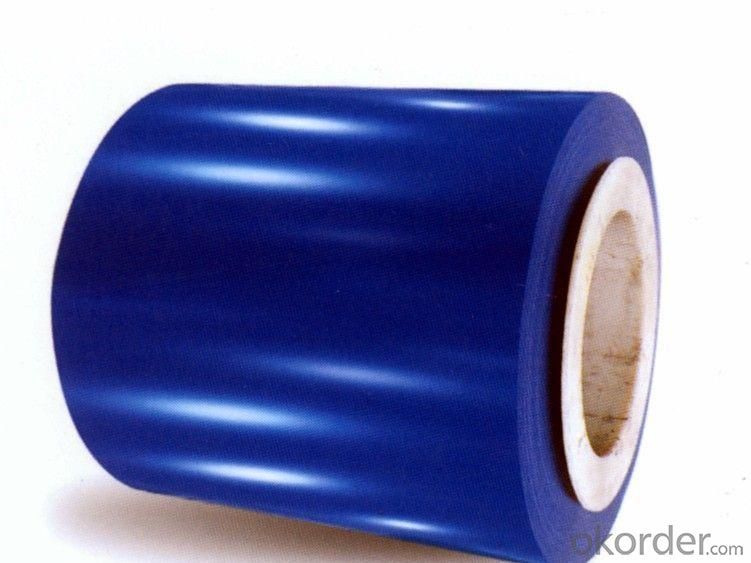

1.Structure of Color Coated Aluminium Coils for Inner Decoration Ceilling

Color Coated Aluminium Coils for Inner Decoration Ceilling is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Coated Aluminium Coils for Inner Decoration Ceilling

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:What is the weight per square foot of 101 aluminum sheets?

- The weight of 101 aluminum sheets per square foot may vary based on the thickness of the sheets. Typically, aluminum weight is measured in pounds per square foot (lbs/ft²). To accurately determine the weight per square foot of 101 aluminum sheets, it is necessary to be aware of the thickness of each individual sheet. Once the thickness is known, the weight per square foot can be calculated by utilizing the density of aluminum, which is approximately 0.098 pounds per cubic inch (lbs/in³).

- Q:Are aluminum sheets suitable for construction purposes?

- Yes, aluminum sheets are suitable for construction purposes. They are lightweight, durable, and resistant to corrosion, making them ideal for various construction applications such as roofing, cladding, and structural components. Additionally, aluminum sheets offer good thermal and electrical conductivity, making them suitable for applications where these properties are required.

- Q:How could two pieces of aluminium flakes be welded together?

- You can use argon arc welding, connect the positive pole with alternating current,aluminum wire as the welding wire.

- Q:How is the coated aluminum mirror plate produced?

- Covered film means the protective film on the surface of the protective materialMirror refers to the aluminum plate after polishing and other processes to deal with reflective rate, or gloss hundred percent effectAluminium plate is raw materialAs for the production process, the aluminum plate is cleaned and pretreated,Then the surface polished, and then plating or coating, transparent UV coloring. Become black mirror, blue mirror and other effectsFinally, the surface is covered with a plastic sticky protective film, namely a laminated mirror aluminum plate

- Q:Are aluminum sheets prone to warping?

- Yes, aluminum sheets can be prone to warping under certain conditions. Aluminum is a relatively soft metal, meaning it is more susceptible to bending or distorting compared to other metals like steel. However, the extent to which aluminum sheets warp depends on various factors such as the thickness of the sheet, the specific alloy used, the temperature it is exposed to, and the level of stress applied to it. Thinner aluminum sheets are generally more prone to warping as they have less structural integrity. Thicker sheets, on the other hand, are more resistant to warping due to their increased rigidity. Additionally, the specific alloy composition of the aluminum sheet can influence its susceptibility to warping. Temperature fluctuations can also cause aluminum sheets to warp. When exposed to high temperatures, aluminum expands, and if not properly supported or restrained, it may bend or warp. Similarly, rapid cooling can cause contraction, resulting in warping. Lastly, the level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can cause the sheet to deform. To minimize warping, it is important to handle aluminum sheets with care, support them adequately during temperature changes, and avoid applying excessive stress. Additionally, using thicker aluminum sheets or choosing certain alloys with higher tensile strength can help mitigate the risk of warping.

- Q:What are the different surface treatments available for aluminum sheet?

- There are several surface treatments available for aluminum sheet, including anodizing, powder coating, painting, and polishing. Anodizing provides a durable and corrosion-resistant finish, while powder coating offers a wide range of colors and enhanced durability. Painting allows for customization with various finishes and colors, while polishing provides a shiny and reflective surface. Each treatment option offers different aesthetic and functional benefits, depending on the specific requirements and desired outcome.

- Q:Are the aluminum sheets suitable for manufacturing chemical storage cabinets?

- Indeed, chemical storage cabinets can be manufactured with aluminum sheets. Aluminum, being a robust and long-lasting material, exhibits corrosion resistance, thus making it an excellent choice for safeguarding chemicals. Its lightweight nature renders transportation and installation more convenient. Moreover, aluminum remains non-reactive with the majority of chemicals, thereby ensuring the safety of stored substances. In summary, the utilization of aluminum sheets offers a dependable and effective solution for the production of chemical storage cabinets.

- Q:My new home has a mix of copper and aluminum wiring. My mother used a shop vac in one of the recepticles last week and blew two of them in my bedroom. Then this weekend my brother was replacing my exhaust fan in the bathroom and that proceeded to blow the entire bedroom and bathroom including ceiling fans, lights and all recepticles. Does anyone have any ideas?

- You said new home. Aluminum hasn't been used in house wiring for many years. It is now only used for the main service wires coming in to the panel. Shop vacs can trip 15 amp bedroom circuits. I think you need to call in an electrician if your dad reset all the breakers. Have him do the exhaust fan too. Let your brother help mom with the cleaning. Forget about doing your own wiring or replacing things yourself. Hire an electrician. The firefighters will thank you.

- Q:Can aluminum sheets be polished?

- Certainly, aluminum sheets are capable of being polished. Aluminum, being a relatively malleable metal, lends itself to easier polishing in comparison to harder metals like stainless steel. The act of polishing aluminum sheets entails the utilization of abrasive substances such as sandpaper or polishing compounds. This serves to eliminate any blemishes, scratches, or oxidation present on the surface. Typically, the process involves multiple stages of polishing, employing varying degrees of grit in sandpaper or polishing compounds. Step by step, a smoother and more reflective surface is attained. Polished aluminum sheets find common usage in various applications, including automotive components, architectural elements, and ornamental objects. The polishing process elevates the metal's aesthetic appeal, imparting a glossy and reflective finish.

- Q:Can aluminum sheet be used for solar panels?

- Yes, aluminum sheets can be used for solar panels. They are commonly used as the backing material or frame for solar panels due to their lightweight, corrosion-resistant, and durable properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminium Coils for Inner Decoration Ceilling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords