Color Coated Aluminium Coil PVDF painting for Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Color Coated Aluminium Coil PVDF painting for Outer Doors

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Color Coated Aluminium Coil PVDF painting for Outer Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminium Coil PVDF painting for Outer Doors

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

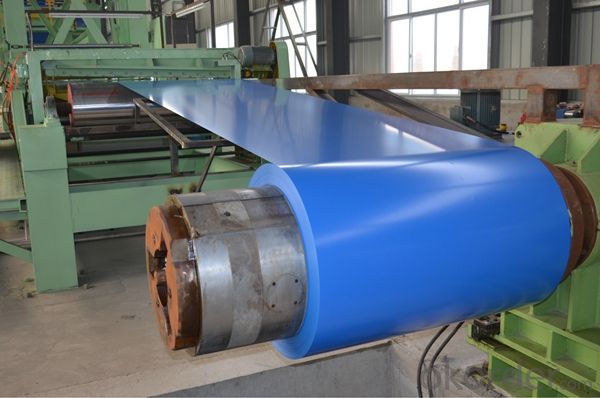

5. Image of Color Coated Aluminium Coil PVDF painting for Outer Doors

6. Package and shipping of Color Coated Aluminium Coil PVDF painting for Outer Doors

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:How do aluminum coils perform in high-pressure applications?

- Aluminum coils perform well in high-pressure applications due to their excellent strength-to-weight ratio and corrosion resistance. They are capable of withstanding high pressures without deformation or failure, making them a reliable choice for various industrial and HVAC systems.

- Q:How do aluminum coils compare to zinc coils in terms of durability?

- The durability of aluminum coils and zinc coils is influenced by their different properties. Aluminum coils are highly durable due to their excellent corrosion resistance. They naturally develop an oxide layer that acts as a protective barrier against rust and degradation. This makes them ideal for use in coastal areas or locations with high humidity levels. In contrast, zinc coils, specifically galvanized steel coils, are coated with a layer of zinc to enhance their corrosion resistance. The zinc coating acts as a sacrificial layer, corroding first and protecting the underlying steel from rust. As a result, zinc coils are also highly durable and can withstand harsh conditions where the steel substrate is exposed to moisture or chemicals. Although both aluminum and zinc coils offer good durability, aluminum coils have an advantage in terms of corrosion resistance. Their natural oxide layer provides continuous protection, while zinc coils rely on the sacrificial zinc coating, which can gradually wear off over time. However, the overall durability of both types of coils depends on factors such as maintenance, usage, and the specific environment in which they are installed.

- Q:How does aluminum ingot be processed to aluminum coil (aluminum sheet)?

- First it should be made into blank and then put on the rolling mill.

- Q:Can aluminum coils be used for food storage containers?

- Indeed, food storage containers can be made from aluminum coils. Aluminum is widely chosen as a material for such containers because of its numerous advantageous qualities. Notably, it is lightweight, sturdy, and possesses exceptional thermal conductivity, enabling it to distribute heat evenly for effective cooking or cooling purposes. Moreover, aluminum is non-toxic, devoid of odor, and resistant to corrosion, rendering it a secure option for food storage. Additionally, it acts as a proficient shield against light, moisture, and oxygen, thereby assisting in maintaining the freshness and quality of the stored food. All in all, opting for aluminum coils for food storage containers can be a dependable and practical decision.

- Q:How do aluminum coils contribute to sustainable energy systems?

- Aluminum coils contribute to sustainable energy systems by being lightweight, durable, and highly conductive, making them ideal for various renewable energy applications. They are commonly used in solar panels, wind turbines, and electric vehicles, as the coils help enhance energy efficiency and reduce carbon emissions. Additionally, aluminum is easily recyclable, promoting a circular economy and reducing the environmental impact of energy systems.

- Q:Can aluminum coils be used for electrical transmission lines?

- Yes, aluminum coils can be and are commonly used for electrical transmission lines. Aluminum has several advantages that make it a suitable choice for transmission lines. First, aluminum is a lightweight material, which makes it easier and more cost-effective to transport and install. Second, aluminum is a good conductor of electricity, with similar conductivity to copper. Third, aluminum is less expensive than copper, making it a more economical option for long-distance transmission lines. However, there are some challenges associated with using aluminum coils in transmission lines. Aluminum has a lower tensile strength compared to copper, which means that it is more prone to sagging over long distances. Additionally, aluminum has a higher thermal expansion coefficient than copper, which can cause issues with thermal expansion and contraction. Despite these challenges, proper design and engineering can ensure that aluminum coils are used effectively and efficiently in electrical transmission lines.

- Q:Some makes like KIA make a point of having aluminum engines. I thought this was for weight, but was more prone to failure, especially in a high mileage car.

- depends. i had a 79 F150, obviously engine made of steel. I let the water run out, the oil run out, the tranny fluid run out, etc. Couldnt kill that truck. I think the aluminum engines built today are fine, depending on the manufacturer. You cant run these engines into the ground though. I have had hondas and toyotas that ran forever with aluminum engines. Chrysler (dodge and plymouth) aluminum engines i have found are junk. I have been told by people who know to never buy a kia. if you can't afford a new car, buy a used one, like toyota, honda, never a nissan though. engines are just as good but the rest of the car is made out of pot metal. mazda is my favorite and many a ford has mazda engineering inside. the ford escape 4 cylinder is what i drive. it has a mazda engine.

- Q:Are aluminum coils suitable for marine environments?

- Yes, aluminum coils are suitable for marine environments. Aluminum has excellent corrosion resistance properties, making it a popular choice for marine applications. It forms a protective oxide layer that prevents further corrosion, making it ideal for withstanding the harsh saltwater and humid conditions found in marine environments. Additionally, aluminum coils are lightweight, durable, and easy to maintain, making them a reliable option for marine applications.

- Q:I am sanding tool marks out of aluminum rims and plan on polishing them. Any help to make sanding them easier would be welcome.

- What kind of finish do they have? Brushed? High reflection? I think that if they are brushed, you may be able to use a steel wool. I'd get a second opinion on that (I'm no expert and my rims knowledge is probably outdated).

- Q:Is aluminum veneer the same as color coated aluminum coil?

- Not necessarily, but you may call it like this. Aluminum veneer is the panel processed by aluminum plant. It has different size and thickness according to customer’s requirements. Color coated aluminum coil has been coated through two processes of bake and roast, for example, the coil or sheet formed of the coating of cars.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Aluminium Coil PVDF painting for Outer Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords