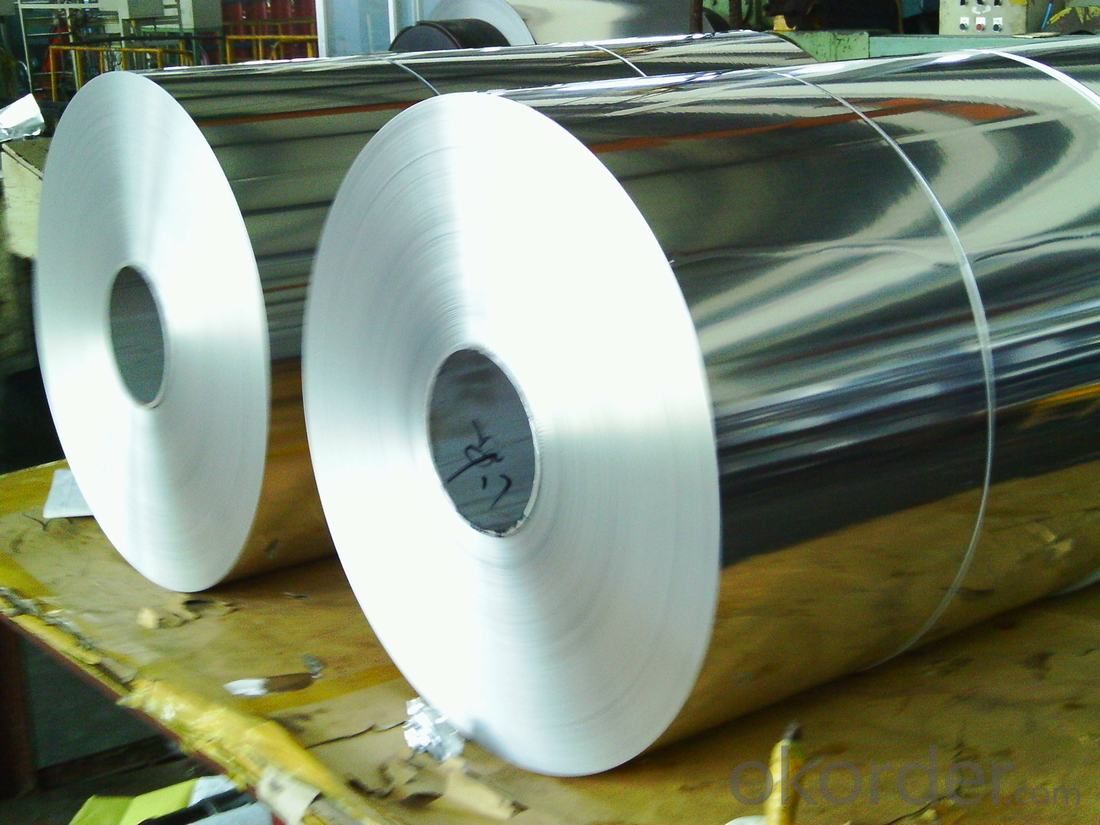

Cold Rolling 1100/1050/1020/1060 Aluminum Coils For Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Grade:

1000 Series,3000 Series,5000 Series

Surface Treatment:

Mill Finish

Shape:

Flat

Temper:

O-H112,Hard,Half Hard

Application:

Decorations,Door & Window

Thickness:

0.08-8mm

Width:

280MM -1500MM

Outer Diameter:

500 MM

Packaging:

Wooden pallet

Cold Rolling 1100/1050/1020/1060 Aluminum Coils For Decoration

Temper: h14,h16,h18,h22,h24,h26,h32,o/f

Thickness: o.o3mm-3.0mm

Width: 30mm-1700mm

Coating: pe(polyester),pvdf,epoxy

Painting thickness: standard 16-25 mic, max 40 mic

Color: according to ral colors or customer's samples

Packaging & Delivery

| Packaging Details: | Coil ID :508MM Coil Weight : about 2.5 tons or as per customers requirement Packing ; In Export Sea worhty wooden pallets Eye to wall or Eye to Sky One container can be loaded about 20 mts |

| Delivery Detail: | within 25 days after receiving L/C deposit |

- Q:Are aluminum sheets suitable for architectural louvers?

- Yes, aluminum sheets are suitable for architectural louvers. Aluminum is a popular material choice for louvers due to its various advantageous properties. Firstly, aluminum is lightweight yet strong, making it an ideal material for architectural louvers. It can withstand external forces such as wind and weather conditions without compromising its structural integrity. This is crucial for louvers, as they need to provide ventilation and airflow while also maintaining their shape and functionality. Secondly, aluminum is highly resistant to corrosion and rust. Louvers are often exposed to outdoor elements, including rain, moisture, and sunlight. Aluminum's resistance to corrosion ensures that the louvers will remain durable and long-lasting, even in harsh environmental conditions. Additionally, aluminum is a versatile material that can be easily customized and fabricated into various shapes and sizes. This allows architects and designers to create louvers with unique designs and configurations to suit specific building requirements. Aluminum louvers can be tailored to provide optimal airflow, light control, and aesthetic appeal. Moreover, aluminum is a sustainable and environmentally friendly material. It is widely recyclable, meaning that aluminum louvers can be easily repurposed or reused at the end of their life cycle. Choosing aluminum for architectural louvers aligns with sustainable building practices and contributes to reducing the overall environmental impact. In conclusion, aluminum sheets are indeed suitable for architectural louvers. Their lightweight, strong, corrosion-resistant, and customizable properties make them an excellent choice for louvers in terms of functionality, durability, and aesthetics.

- Q:What are the typical uses or applications for 101 aluminum sheets?

- 101 aluminum sheets are commonly used in a variety of applications due to their unique properties. Some typical uses for 101 aluminum sheets include: 1. Automotive industry: 101 aluminum sheets are widely used in the automotive industry for manufacturing vehicle bodies, panels, and other components. Their lightweight nature, corrosion resistance, and high strength-to-weight ratio make them ideal for improving fuel efficiency and reducing overall vehicle weight. 2. Construction industry: These aluminum sheets are extensively used in construction projects for roofing, cladding, and facades. They provide excellent durability, weather resistance, and easy formability, making them suitable for various architectural applications. 3. Packaging industry: 101 aluminum sheets are commonly used in the packaging industry for manufacturing cans, containers, and foils. Their malleability and ability to retain the freshness and quality of food make them a preferred choice for packaging perishable goods. 4. Electrical industry: Due to their excellent conductivity and low electrical resistance, 101 aluminum sheets are frequently used in the electrical industry for manufacturing power transmission lines, bus bars, and electrical enclosures. They offer superior heat dissipation properties, making them ideal for applications requiring efficient heat transfer. 5. Marine industry: The corrosion-resistant properties of 101 aluminum sheets make them suitable for marine applications. They are often used in boat building, shipbuilding, and offshore structures, as they can withstand the harsh saltwater environment without significant degradation. 6. Aerospace industry: 101 aluminum sheets find extensive use in the aerospace industry for manufacturing aircraft components such as wings, fuselages, and structural parts. Their lightweight nature and high strength make them crucial for reducing the overall weight of aircraft and increasing fuel efficiency. 7. Household appliances: These aluminum sheets are commonly used in the manufacturing of household appliances like refrigerators, air conditioners, and cookware. Their thermal conductivity, durability, and resistance to corrosion make them suitable for various applications in the home. Overall, 101 aluminum sheets have a wide range of uses and applications across various industries due to their exceptional properties, including lightweight, corrosion resistance, durability, and formability.

- Q:Are the aluminum sheets suitable for manufacturing kitchen utensils?

- Indeed, aluminum sheets prove to be exceptionally well-suited for the production of kitchen utensils. Boasting a lightweight and enduring composition, aluminum exhibits remarkable heat dispersal qualities. Its resistance to corrosion renders it an ideal choice for direct contact with food and liquids. Furthermore, its non-reactive nature ensures that no detrimental substances permeate the cooked or stored items. The ease with which it can be cleansed and maintained only adds to its appeal, thus cementing its popularity among kitchen utensil enthusiasts. All in all, aluminum sheets emerge as a dependable and productive alternative for fabricating an extensive variety of kitchen utensils.

- Q:To rephrase- in our physics class we found that a simple bar magnet wouldn't attract to an aluminum gutter nail, but our teacher told us to find out whether or not any magnet could lift up the aluminum material. If you answer please give a reference or source, or at least an idea on how to go about researching this, all help appreciated, thanks and God Bless!

- It is the wish of every person to be effective in all his endeavors. Everyone desires to have a quality life without any worries and stress.

- Q:What is the typical creep resistance of aluminum sheets?

- The typical creep resistance of aluminum sheets is relatively low compared to other materials, such as steel. Aluminum has a lower melting point and weaker crystal structure, making it more prone to creep deformation under high temperatures and sustained loads. However, aluminum alloys can be specifically engineered to enhance creep resistance by adding alloying elements and heat treatment processes.

- Q:Can the aluminum sheets be used in the construction industry?

- Certainly, the construction industry can make effective use of aluminum sheets. Aluminum proves to be a highly adaptable and lightweight material, offering numerous advantages for construction purposes. Its resistance to corrosion makes it especially suitable for outdoor structures and buildings. Roofing, siding, window frames, doors, and other architectural components often incorporate aluminum sheets. Moreover, aluminum's exceptional strength-to-weight ratio enables the creation of sturdy and efficient structures. Its malleability also facilitates easy fabrication and shaping into various forms, allowing for imaginative and groundbreaking designs in construction projects. Overall, aluminum sheets remain a widely favored choice in the construction industry due to their enduring nature, adaptability, and aesthetic appeal.

- Q:What are the different types of surface treatments available for aluminum sheets?

- There are several different types of surface treatments available for aluminum sheets, including anodizing, powder coating, painting, polishing, and brushing. These treatments can enhance the appearance, durability, corrosion resistance, and overall performance of the aluminum sheets.

- Q:Can aluminum sheets be used for battery enclosures?

- Yes, aluminum sheets can be used for battery enclosures. Aluminum is commonly used in battery enclosures due to its lightweight, corrosion-resistant, and electrically conductive properties. It provides a protective casing for the battery, ensuring safety and efficient performance.

- Q:im wanting to try and source my own chemicals for experiments and such in the cheapest way possiblei thought a cheap method of making powdered aluminium would be to just sandpaper aluminium kitchen foil and collect the powder, what i need to know is:how pure is aluminium foil?.....e.g is it actually mixed with some other metals and is an alloyand will the powder i collect be as good as bottled aluminium powder? i know it wont be perfect but as long as its similar that should be fineim using it for pyrotechnical experiments by the way

- Aluminum foil is pretty pure for most purposes (99.1 % pure). However, I really think sandpapering aluminum foil is not your best option. For one, aluminum foil is quite expensive, I wonder if you could just get a bunch of the powder for a cheaper price than buying an equal mass of aluminum foil. Also, how would you even begin sandpapering it? If you rub a crumpled up ball of aluminum on a rough surface, you don't get a powder, you just get a ripped up ball and a gray mark on the rough surface. But you could try, tell me if it works. However, I think you may have better odds with aluminum cans. They are cheaper and thicker thus not so prone to ripping. Although I still doubt you could get a reasonable quantity of aluminum powder from that. If all else fails, you could always try stuffing a bunch of aluminum foil in a blender.

- Q:Can the aluminum sheets be used for manufacturing furniture?

- Yes, aluminum sheets can certainly be used for manufacturing furniture. Aluminum is a lightweight and strong material, making it ideal for creating furniture that is both durable and easy to move around. Additionally, aluminum is resistant to corrosion, so it can withstand exposure to various environmental conditions. Moreover, aluminum sheets can be easily shaped and formed into different designs, allowing for versatility in furniture manufacturing. Overall, using aluminum sheets for furniture manufacturing can result in high-quality, stylish, and long-lasting pieces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolling 1100/1050/1020/1060 Aluminum Coils For Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords