Cold Rolled Steel Coils Grade 304 NO.2B from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Cold Rolled Steel Coils Grade 304 NO.2B from China

Products Despription

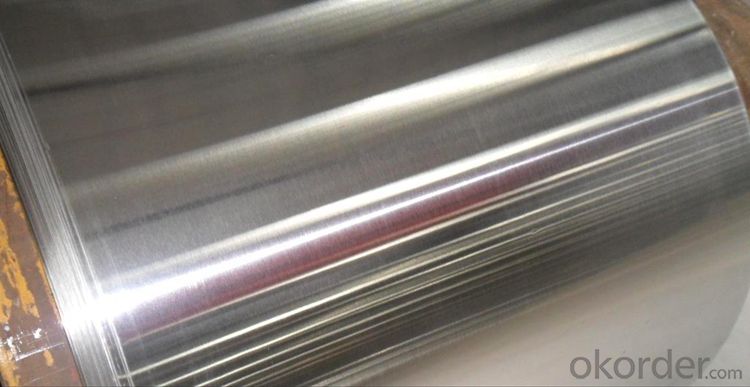

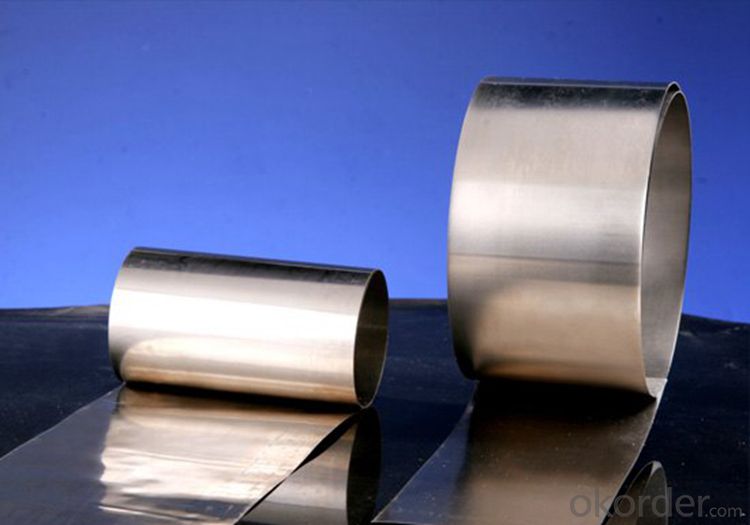

Name:stainless steel coils/plates/sheets

Delivery Port :Any Port, China

Coil Weight :20 Tons

Grade :201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc.

Technique :Cold Rolled

Finish :2B, BA, 2D, No1, No2, No4,NO.8,SB etc

Edge :Mill Edge / Slitting Edge

Size: Thickness0.3-6mm,Width:280-2000mm

Package :as customer's requirement

Place of Origin :made in China

MOQ :20 Tons

Payment Terms :100% LC at sight,or 100%TT in advance

Delivery Time :With 15- 20 days after deposit

Detail of Picture

Application

2B Medical equipment, Food industry, Construction material, Kitchen utensils.

NO.1 Chemical tank, pipe.

- Q:Can stainless steel sheets be used for chemical reactors?

- Yes, stainless steel sheets can be used for chemical reactors. Stainless steel is a popular choice for chemical reactors due to its excellent corrosion resistance properties. It is highly resistant to chemical reactions with various substances, making it suitable for handling corrosive chemicals or environments. Stainless steel sheets are also known for their durability, high strength, and ability to withstand high temperatures, making them suitable for use in chemical reactors that may operate under extreme conditions. Additionally, stainless steel is easy to clean and maintain, which is crucial for ensuring the purity and integrity of the reaction process. Overall, stainless steel sheets are widely used in the construction of chemical reactors and are considered a reliable and effective material choice for this application.

- Q:Are stainless steel sheets resistant to saltwater corrosion?

- Yes, stainless steel sheets are highly resistant to saltwater corrosion due to their composition, which includes chromium that forms a protective oxide layer on the surface, preventing corrosion when exposed to saltwater.

- Q:Can stainless steel sheets be used for medical equipment?

- Indeed, medical equipment can utilize stainless steel sheets. The medical industry extensively employs stainless steel due to its remarkable resistance to corrosion, its durability, and its ease of cleaning. Surgical instruments, implants, medical devices, and equipment like sterilization trays, hospital beds, and operating room tables are commonly manufactured using stainless steel. As it does not react with bodily tissues or fluids, stainless steel is a secure and sanitary option for medical purposes. Moreover, it can endure numerous sterilization procedures without compromising its qualities, thus rendering it perfectly suited for hospitals and healthcare facilities.

- Q:Are stainless steel sheets suitable for elevator wall panels?

- Indeed, elevator wall panels can be made from stainless steel sheets. The use of stainless steel is quite popular for such panels due to its strong and enduring nature, as well as its ability to resist corrosion. Given that elevators are areas with high foot traffic, it is crucial to select a material that can withstand constant usage and potential impact. Stainless steel sheets are resilient and can endure the wear and tear associated with elevator usage. Moreover, stainless steel possesses a remarkable resistance to corrosion, making it a suitable choice for environments that experience high humidity or exposure to chemicals. Furthermore, stainless steel adds a sleek and contemporary touch to the interior of elevators, enhancing their elegance. Overall, stainless steel sheets are a dependable and visually pleasing option for elevator wall panels.

- Q:What are the different types of stainless steel sheet finishes for industrial applications?

- There are several types of stainless steel sheet finishes for industrial applications, including 2B, No. 4, No. 8, BA, and brushed finishes.

- Q:How to clean stainless steel plate cleaning?

- The mild way to clean stainless steel is simply to use hot water and clean soft cloth to wipe the surface, and then use dry metal with other soft cloth to prevent water stains thoroughly. I'm surprised at how much dirt on the surface comes to my pizza oven, just this step. When using this or any other way, please remember, "grain" stainless steel has run the whole surface in one direction on the minor groove metal and its best grain, rather than across it clean. Some people will tell you that this is to avoid scratching the metal or lodging the dust particles in the foods, where they can cause rust to form. This is likely to be true, but scrubbing food seems to be easier and more effective.

- Q:What is the thermal expansion coefficient of stainless steel sheets?

- The thermal expansion coefficient of stainless steel sheets is subject to variation based on the specific grade and composition of the stainless steel. In comparison to other metals, stainless steel generally possesses a lesser thermal expansion coefficient. The typical range for the coefficient of thermal expansion in stainless steel sheets falls between 10.8 x 10^-6 to 18.0 x 10^-6 per degree Celsius. It should be noted that this coefficient may undergo slight variation among different stainless steel alloy types.

- Q:Who knows the production process of stainless steel plate?

- Stainless steel surface process:Stainless steel has a variety of surface processing to broaden its application areas, different surface processing makes the surface of stainless steel different, making it unique in the application.The corrosion environment requires smooth surface for smooth surface is not easy to fouling. Deposition of dirt can make stainless steel rusty and even cause corrosion.In the spacious lobby, stainless steel is the most commonly used decorative materials for the elevator decoration, although the surface of the fingerprint can erase, but affect the appearance, it is best to use the appropriate surface to prevent leaving fingerprints.

- Q:How do I prevent finger marks on stainless steel sheets?

- To prevent finger marks on stainless steel sheets, you can try a few simple steps. Firstly, make sure to clean the sheets regularly using a mild detergent or stainless steel cleaner to remove any existing fingerprints. Next, consider applying a protective coating or film specifically designed for stainless steel surfaces, which can provide a barrier against smudges and fingerprints. Additionally, try to handle the sheets with clean and dry hands to minimize the transfer of oils and dirt. Finally, consider using microfiber or lint-free cloths for cleaning instead of rough materials that can leave scratches or streaks.

- Q:Can stainless steel sheets be used for facade cladding?

- Indeed, facade cladding can make use of stainless steel sheets. This material, known for its high durability and resistance to corrosion, proves to be an excellent choice for exterior applications like facade cladding. Not only does it provide a sleek and reflective surface, but it also offers an appealing and contemporary aesthetic. Moreover, stainless steel sheets come in various finishes, including brushed, mirror, and patterned, thereby offering a wide range of design possibilities. Additionally, maintaining stainless steel is a breeze, requiring minimal cleaning and upkeep. All things considered, stainless steel sheets have become a popular and practical option for facade cladding due to their durability, aesthetic appeal, and low maintenance requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolled Steel Coils Grade 304 NO.2B from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords