Cold Rolled Steel 304,Cold Rolled Steel Plates Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

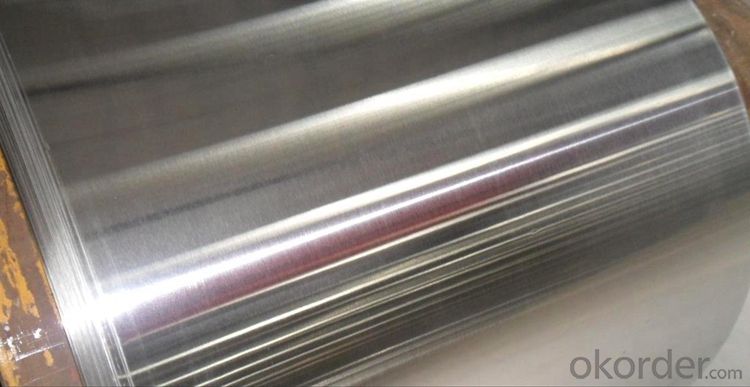

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q:Can stainless steel sheets be used for heat recovery systems?

- Yes, stainless steel sheets can be used for heat recovery systems. Stainless steel is widely recognized for its high thermal conductivity and corrosion resistance, making it an ideal material for heat transfer applications. In heat recovery systems, stainless steel sheets are often used as heat exchanger plates or tubes due to their ability to efficiently transfer heat from one fluid to another. The corrosion resistance of stainless steel ensures the longevity and reliability of the heat recovery system, even when exposed to high temperatures and aggressive environments. Additionally, stainless steel sheets can withstand thermal expansion and contraction, making them suitable for various heat recovery system designs. Overall, stainless steel sheets are a popular choice in heat recovery systems due to their excellent heat transfer properties, durability, and resistance to corrosion.

- Q:What are the different types of punched finishes available for stainless steel sheets?

- There are several types of punched finishes available for stainless steel sheets, including round hole, square hole, slotted hole, and decorative patterns. Each type offers a unique aesthetic and functional purpose, allowing for customized designs and applications.

- Q:Can stainless steel sheets be used in food processing applications?

- Stainless steel sheets are indeed applicable for use in food processing activities. The reason behind the popularity of stainless steel in food processing equipment is its remarkable resistance against corrosion, its durability, and its hygienic characteristics. This material possesses a high level of resistance against staining, rusting, and contamination, making it perfectly suitable for direct interaction with food items. Stainless steel sheets are frequently employed in various areas of commercial kitchens and food processing facilities, such as countertops, work tables, and food preparation zones. Furthermore, stainless steel exhibits ease of cleaning and maintenance, which plays a crucial role in guaranteeing food safety and compliance with industry regulations.

- Q:Stainless steel plate more than the thickness of the wire can not be drawn ah?

- Now all is OK, thick is sanded paper, that grind only, processing cost is high8K can be used in medium plate mill

- Q:Can stainless steel sheets be used for architectural purposes?

- Yes, stainless steel sheets can be used for architectural purposes. This material is highly versatile and offers excellent durability, corrosion resistance, and aesthetic appeal, making it a popular choice for architectural applications such as facades, cladding, roofing, and decorative features. Stainless steel sheets can be shaped, formed, and finished to meet various design requirements, making them suitable for both functional and decorative architectural elements.

- Q:Are stainless steel sheets suitable for structural applications?

- Stainless steel sheets, indeed, prove to be appropriate for structural applications. This material, known for its versatility and durability, boasts a remarkable strength-to-weight ratio, rendering it highly suitable for diverse structural purposes. Its exceptional corrosion resistance is particularly vital for structures subjected to severe environmental conditions or chemical exposure. Utilizing stainless steel sheets in the fabrication of bridges, buildings, and other structural elements ensures the attainment of necessary robustness and longevity. Moreover, stainless steel stands as a sustainable choice due to its complete recyclability, thereby further augmenting its appropriateness for structural applications.

- Q:Can stainless steel sheets be used for filtration applications?

- Yes, stainless steel sheets can be used for filtration applications. Stainless steel is known for its corrosion resistance and durability, making it an excellent choice for filtration systems. The sheets can be formed into various filter elements, such as screens, discs, or cartridges, to suit different filtration needs. Stainless steel sheets offer high mechanical strength, allowing them to withstand high pressures and temperatures without deformation. Additionally, stainless steel can be easily cleaned and sanitized, making it suitable for applications where hygiene is crucial, such as in the food and beverage industry. Overall, stainless steel sheets are widely used in filtration applications due to their excellent performance and reliability.

- Q:What is the difference between brushed and polished stainless steel sheets?

- The appearance and texture of brushed and polished stainless steel sheets vary. Brushed sheets have a matte finish achieved by brushing the surface with an abrasive material, which creates parallel lines or patterns. This finish helps conceal scratches and fingerprints, making it popular for durable applications. On the other hand, polished sheets have a glossy finish achieved by polishing with a fine abrasive compound. This process eliminates imperfections and scratches, resulting in a mirror-like reflection. The polished finish is more visually appealing and commonly used for decorative purposes. In summary, the main distinction between brushed and polished stainless steel sheets lies in their appearance and texture. Brushed sheets have a textured, matte finish that is more resistant to scratches and fingerprints, while polished sheets have a smooth, glossy finish that provides a mirror-like reflection. The choice depends on the desired aesthetic and specific application requirements.

- Q:What is the general width range of stainless steel sheet? What are the common widths?

- Standard 3 M2 1220*2440 thickness from 1 to 12. The whole volume is hard to say.

- Q:How do you prevent warping or distortion in stainless steel sheets?

- To prevent warping or distortion in stainless steel sheets, several measures can be taken. First, it is important to properly handle and store the sheets to prevent any bending or twisting during transportation or storage. Secondly, ensuring a smooth and even distribution of heat during welding or fabrication processes can help minimize the chances of warping. Additionally, using proper clamping techniques and supports during machining or cutting operations can help maintain the shape and integrity of the stainless steel sheets. Lastly, adhering to the recommended thicknesses and specifications provided by the manufacturer for specific applications can also help prevent warping or distortion in stainless steel sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolled Steel 304,Cold Rolled Steel Plates Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords