Cold Rolled Stainless Steel sheets NO.2B Finish Grade 304 Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

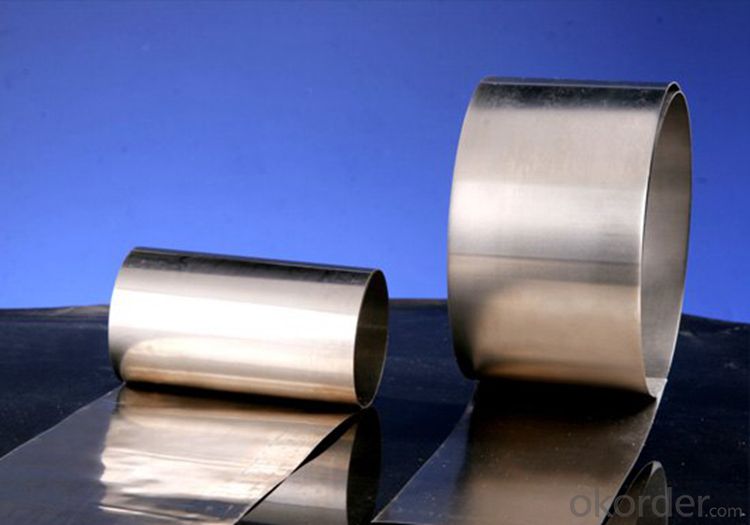

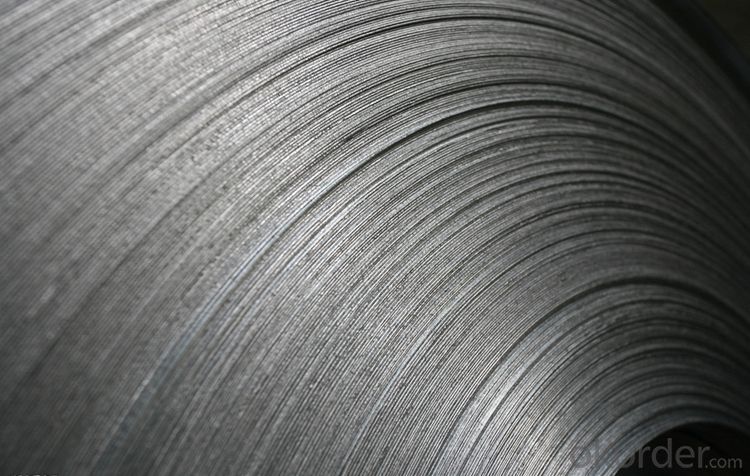

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q:Can stainless steel sheets be used for solar panel frames?

- Yes, stainless steel sheets can be used for solar panel frames. Stainless steel is a popular choice for solar panel frames due to its high strength, durability, and corrosion resistance properties. It can withstand various weather conditions, including extreme heat, humidity, and exposure to sunlight. Additionally, stainless steel is non-magnetic and non-combustible, making it a safe choice for solar panel installations. Its high strength-to-weight ratio also allows for lighter frame designs, reducing the overall weight of the solar panels and making them easier to install. Overall, stainless steel sheets are a reliable and long-lasting option for constructing solar panel frames.

- Q:What are the benefits of using patterned stainless steel sheets in interior design?

- There are numerous advantages to utilizing patterned stainless steel sheets in interior design. To begin, these sheets bring a distinct and contemporary aesthetic to any area. The patterns etched onto the stainless steel come in a variety of designs, ranging from geometric shapes to intricate motifs, adding a touch of elegance and visual interest to walls, ceilings, or furniture. This can enhance the overall ambiance of a room and make it truly stand out. Additionally, patterned stainless steel sheets are incredibly durable and long-lasting. Stainless steel is well-known for its strength and resistance to corrosion, making it an ideal material for interior design applications. These sheets can withstand daily wear and tear, making them suitable for high-traffic areas such as restaurants, hotels, or public spaces. Furthermore, patterned stainless steel sheets require minimal maintenance. Unlike other materials, stainless steel is easy to clean and does not require special care or regular maintenance. A simple wipe with a damp cloth or the use of mild cleaning agents is sufficient to keep the sheets looking pristine. This makes them a practical choice for interior design, especially in areas where hygiene is crucial. Moreover, patterned stainless steel sheets offer design versatility. They can be used in various applications, including wall cladding, room dividers, backsplashes, or even as decorative accents. With a wide range of patterns and finishes available, designers have the freedom to create unique and customized looks to suit any style or theme. Lastly, incorporating patterned stainless steel sheets into interior design is environmentally friendly. Stainless steel is a recyclable material, meaning it can be reused or repurposed without causing harm to the environment. By incorporating sustainable materials into interior design, we contribute to reducing waste and promoting eco-conscious practices. In conclusion, the use of patterned stainless steel sheets in interior design provides benefits such as aesthetic appeal, durability, low maintenance requirements, versatility, and environmental friendliness. These sheets offer a practical and visually pleasing solution to elevate the design of any space.

- Q:What are the different types of stainless steel sheet perforations available?

- There exists a variety of stainless steel sheet perforations, each possessing its own distinctive characteristics and applications. Among the most prevalent types are: 1. Round hole perforations: These perforations, characterized by evenly spaced round holes, are the simplest and most commonly employed. They ensure sufficient airflow and visibility. 2. Square hole perforations: Similar to their round counterparts, square hole perforations offer a distinct aesthetic and may be utilized for ventilation or decorative purposes. 3. Slotted perforations: Elongated in shape, slotted holes provide a larger open area compared to round or square holes. Consequently, they are often employed for drainage or filtering applications. 4. Hexagonal hole perforations: Hexagonal holes, featuring an exclusive pattern, are frequently used for architectural or decorative applications. They are also effective in facilitating airflow and visibility. 5. Decorative perforations: These perforations exhibit diverse shapes and designs, such as floral, geometric, or abstract patterns. Primarily employed for decorative purposes, they are commonly found in building facades or interior design. 6. Micro-perforations: These minute holes, typically less than 1mm in diameter, are utilized in applications necessitating high precision and fine filtration, like speaker grills or air diffusers. When selecting the appropriate perforation type, it is crucial to consider the specific requirements of your application. Factors such as open area, strength, visibility, and aesthetics must all be carefully evaluated to guarantee the most suitable choice for your specific needs.

- Q:Are stainless steel sheets resistant to heat?

- Yes, stainless steel sheets are highly resistant to heat. Stainless steel is a type of steel alloy that contains a high percentage of chromium, which provides excellent heat resistance properties. This enables stainless steel sheets to withstand high temperatures without warping, deforming, or losing their structural integrity. Stainless steel sheets are commonly used in applications that require heat resistance, such as in the construction of ovens, cookware, industrial equipment, and automotive parts. Additionally, stainless steel sheets also have good oxidation resistance, which means they can maintain their appearance and properties even at elevated temperatures. Overall, stainless steel sheets are an excellent choice for applications where heat resistance is a crucial requirement.

- Q:Are stainless steel sheets suitable for heat exchangers?

- Indeed, heat exchangers find stainless steel sheets to be a suitable material. This is due to the fact that stainless steel exhibits exceptional thermal conductivity, allowing for efficient heat transfer between fluids. Moreover, stainless steel boasts high resistance against corrosion and oxidation, rendering it an ideal choice for instances where contact with diverse fluids or gases at varying temperatures is anticipated. Furthermore, the durability and capacity to endure elevated temperatures enhance stainless steel's dependability as a preferred option for heat exchangers. In conclusion, stainless steel sheets are widely favored and trusted in the realm of heat exchangers owing to their thermal conductivity, corrosion resistance, and durability.

- Q:Are stainless steel sheets suitable for marine propellers?

- Yes, stainless steel sheets are suitable for marine propellers. Stainless steel is highly resistant to corrosion and provides excellent strength and durability, making it ideal for marine environments where propellers are constantly exposed to water and salt. Additionally, stainless steel has good performance in terms of balancing, vibration, and noise reduction, making it a preferred choice for marine propellers.

- Q:What's the cheapest kind of stainless steel plate? What's the model and how much is it?

- The cheapest is 201, the price is relative to the thickness

- Q:Can stainless steel sheets be used for elevator panels?

- Indeed, elevator panels can make use of stainless steel sheets. Stainless steel, being highly durable, strong, and visually appealing, is a favored material for elevator panels. Its resistance to corrosion, damage, and wear makes it ideal for high-traffic regions such as elevators. Furthermore, stainless steel panels are effortless to clean and maintain, which is crucial for preserving a pristine and polished appearance within elevators. Moreover, stainless steel can be easily tailored and manufactured to suit precise elevator dimensions and design necessities. All in all, stainless steel sheets represent a dependable and adaptable choice for elevator panels.

- Q:What are the different types of stainless steel sheet patterns available?

- There are several different types of stainless steel sheet patterns available, including plain, diamond, quilted, and hammered. Plain patterns have a smooth, flat surface, while diamond patterns feature raised diamond-shaped ridges. Quilted patterns have a decorative quilt-like design, and hammered patterns have a textured, hammered appearance. These various patterns offer different aesthetic options for stainless steel sheets.

- Q:Can stainless steel sheets be used for food storage containers?

- Yes, stainless steel sheets can be used for food storage containers. Stainless steel is a safe and hygienic material for storing food as it is non-reactive, resistant to corrosion, and does not leach any harmful substances into the food. It is commonly used in commercial kitchens and food processing industries due to its durability and ease of cleaning.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolled Stainless Steel sheets NO.2B Finish Grade 304 Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords