cold rolled stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless Steel round Bar

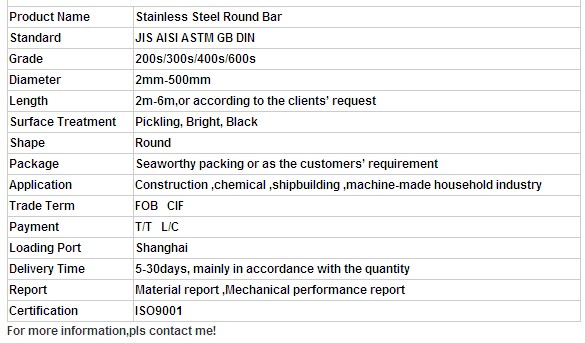

Specifications

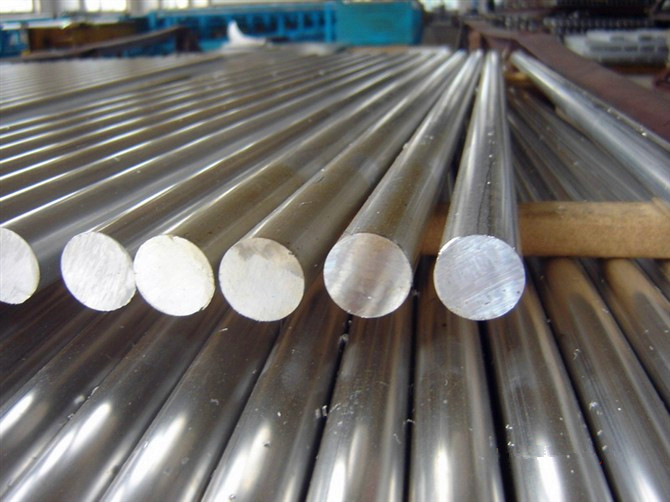

stainless steel round bar

1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

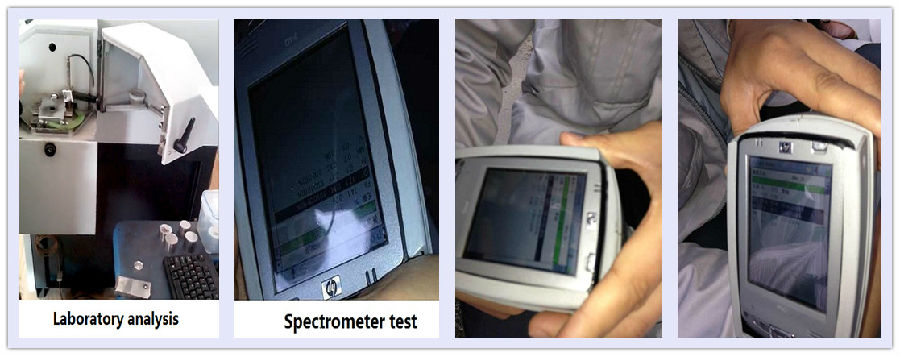

A series of pictures

- Q:Are stainless steel bars suitable for aerospace applications?

- Yes, stainless steel bars are suitable for aerospace applications. Stainless steel possesses excellent strength, corrosion resistance, and heat resistance properties, making it an ideal material for various aerospace components like aircraft frames, engine parts, and landing gear. Additionally, stainless steel's high strength-to-weight ratio and durability contribute to its suitability for aerospace applications, ensuring safety and performance in demanding environments.

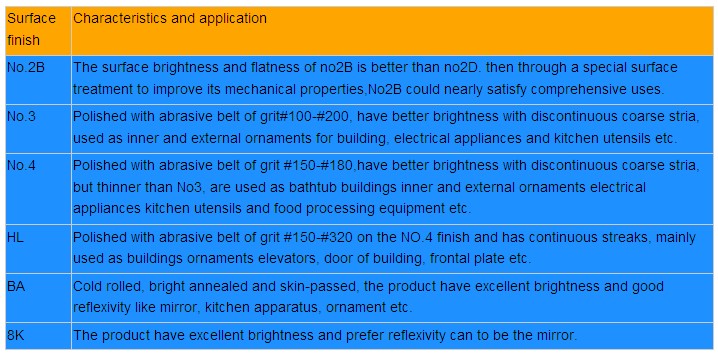

- Q:What are the different types of surface treatments for stainless steel bars?

- For stainless steel bars, there are a variety of surface treatments available, each with its own distinct benefits and characteristics. 1. Passivation: By using an acid solution, impurities and contaminants on the stainless steel surface can be removed. Passivation enhances the material's corrosion resistance and improves its overall appearance. 2. Pickling: A strong acid solution is used to immerse the stainless steel bar, effectively eliminating scale, oxide, and other surface impurities. This treatment is commonly employed to prepare the surface for subsequent treatments or to restore the stainless steel's original appearance. 3. Electro-polishing: An electrolyte solution and electric current are utilized in this treatment to remove a thin layer from the stainless steel surface. Electro-polishing results in a smooth and shiny finish, improves corrosion resistance, and reduces the risk of bacterial growth on the surface. 4. Mechanical polishing: By employing abrasive materials, surface imperfections are eliminated, creating a smooth and reflective finish. Mechanical polishing can be carried out manually or with the aid of machines, depending on the desired outcome. 5. Coating: Various materials can be used to coat stainless steel bars, providing added protection and enhancing performance in specific applications. Common coatings include powder coating, PVD (Physical Vapor Deposition), and electroplating. 6. Brushing: This technique involves using abrasive brushes or pads to create a textured or satin finish on the stainless steel surface. Brushing helps conceal scratches and imperfections while imparting a unique aesthetic appeal. It is important to consider the intended use and requirements of the stainless steel bars when selecting a surface treatment. Each treatment offers different advantages, such as improved corrosion resistance, enhanced appearance, or increased durability. Seeking guidance from professionals or suppliers can assist in determining the most suitable surface treatment for a specific application.

- Q:What is the density of different grades of stainless steel bars?

- The specific grade of stainless steel bars can cause variations in their density. On average, stainless steel typically has a density of approximately 7.9 grams per cubic centimeter (g/cm³). It should be emphasized that density can slightly differ among different grades of stainless steel due to variances in composition and alloying elements. In general, stainless steels with higher alloy content tend to exhibit a slightly greater density in comparison to those with lower alloy content.

- Q:Can stainless steel bars be used in watch straps?

- Yes, stainless steel bars can be used in watch straps. Stainless steel is a popular choice for watch strap materials due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel bars are commonly used to connect the watch strap to the watch case. These bars, also known as spring bars or lug bars, are inserted into the lugs on either side of the watch case and secure the strap in place. They provide a secure and reliable attachment, ensuring that the watch strap remains in position during regular wear. Stainless steel bars are available in various sizes and can be easily replaced if needed.

- Q:Are stainless steel bars resistant to hydrochloric acid corrosion?

- Yes, stainless steel bars are generally resistant to hydrochloric acid corrosion. Stainless steel contains a high amount of chromium, which forms a protective oxide layer on the surface of the metal. This oxide layer acts as a barrier, preventing the acid from reaching the underlying metal and causing corrosion. However, the resistance of stainless steel to hydrochloric acid corrosion can vary depending on the grade and composition of the stainless steel. Some grades of stainless steel, such as 304 and 316, have higher resistance to hydrochloric acid corrosion compared to others. It is always recommended to consult with a corrosion specialist or refer to the specific grade's corrosion resistance data sheets to determine the suitability of stainless steel bars for a particular application involving hydrochloric acid.

- Q:Can stainless steel bars be cold worked?

- Stainless steel bars possess the capability to undergo cold working, a procedure that involves subjecting them to deformation at room temperature. This can be achieved through diverse techniques, including forging, bending, rolling, and drawing. Employing cold working frequently aids in enhancing the strength, hardness, and dimensional precision of stainless steel bars. Additionally, it contributes to refining the surface finish and eliminating flaws. Nevertheless, it is crucial to bear in mind that excessive cold working may result in the corrosion resistance of stainless steel bars being compromised. Hence, it becomes imperative to strike a balance between attaining the desired properties and preserving the stainless steel's capacity to resist corrosion.

- Q:What are the various surface defects that can occur in stainless steel bars?

- There are several surface defects that can occur in stainless steel bars. Some of the most common ones include: 1. Pitting: Pitting is characterized by small, localized areas of corrosion on the surface of the stainless steel bar. These pits can be caused by various factors such as exposure to corrosive environments, improper cleaning or passivation processes, or chemical reactions. 2. Scale: Scale refers to the formation of a thick, adherent layer of oxides on the surface of the stainless steel bar. This can occur during the manufacturing process or due to high temperatures during use. Scale can negatively affect the appearance and corrosion resistance of the stainless steel. 3. Scratches and gouges: Stainless steel bars can develop scratches and gouges during handling, transportation, or processing. These surface defects can compromise the integrity and aesthetics of the bar, making it more susceptible to corrosion and other damage. 4. Roll marks: Roll marks are impressions or indentations on the surface of the stainless steel bar caused by the rolling process during manufacturing. These marks can vary in severity and can affect the appearance and performance of the bar. 5. Inclusions: Inclusions are foreign particles or impurities embedded in the stainless steel bar's surface. They can be caused by a variety of factors such as improper melting or casting processes, contamination during manufacturing, or poor quality control. Inclusions can lead to localized corrosion or mechanical failures in the stainless steel. 6. Decarburization: Decarburization refers to the loss of carbon from the surface of the stainless steel bar, resulting in a lower carbon content in that area. This can occur during high-temperature processes such as annealing or heat treatment. Decarburization can reduce the mechanical strength and hardness of the stainless steel, making it more susceptible to wear and deformation. It is important to note that these surface defects can vary in severity and impact depending on the specific application and industry requirements. Regular inspection, quality control measures, and proper handling and storage practices can help minimize the occurrence and impact of these defects in stainless steel bars.

- Q:What are the different shapes and sizes of stainless steel bars available?

- Stainless steel bars are available in various shapes and sizes, including round, square, hexagonal, and flat bars. The round bars typically range from 1/4 inch to 12 inches in diameter, while the square and hexagonal bars can vary from 1/4 inch to 4 inches. Flat bars come in different widths and thicknesses, ranging from 1/8 inch to 6 inches. These diverse shapes and sizes allow stainless steel bars to be used in a wide range of applications across industries.

- Q:Can stainless steel bars be used in wind turbine structures?

- Yes, stainless steel bars can be used in wind turbine structures. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for use in outdoor and harsh environments such as wind turbine installations. The strength and structural integrity of stainless steel bars make them ideal for supporting the weight and load of wind turbine components. Additionally, stainless steel has a high fatigue strength, which is crucial for withstanding the constant and repetitive stress that wind turbines experience due to wind forces. Furthermore, stainless steel bars can be fabricated and customized to meet the specific design requirements of wind turbine structures, ensuring a reliable and long-lasting solution.

- Q:Can stainless steel bars be used in marine applications?

- Indeed, stainless steel bars find utility in marine applications. Renowned for their ability to resist corrosion, stainless steel bars prove to be an optimal choice for deployment in marine settings, where they are consistently exposed to saltwater, moisture, and other corrosive factors. Frequently employed in an array of marine applications, including boat fittings, marine hardware, anchor chains, propeller shafts, and other components necessitating robust strength and corrosion resistance, stainless steel bars also garner favor for their visually appealing aesthetics and remarkable durability. Even when subjected to the harshest marine conditions, stainless steel bars retain both their structural integrity and their alluring appearance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

cold rolled stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords