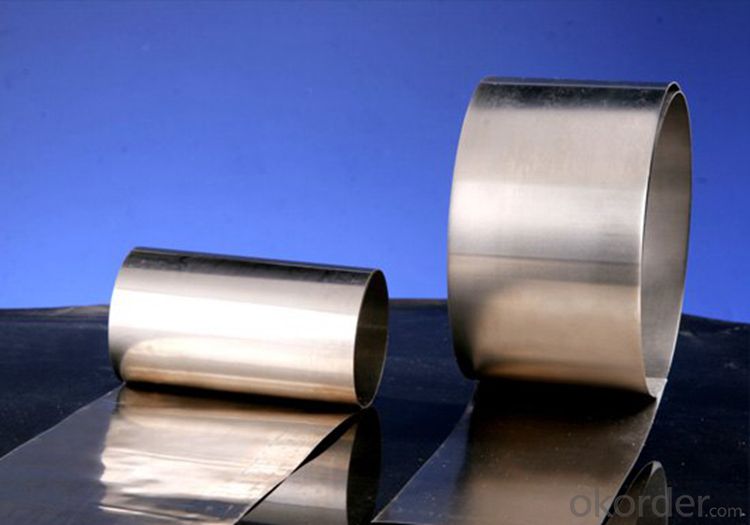

Cold Rolled Stainless Steel Coils,Stainless Steel Sheets Grade 304L NO.2B Finish Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q:How high is the temperature of 2520 stainless steel?

- 310S is a good oxidation resistance, corrosion resistance, high temperature resistance, because the higher percentage of chromium and nickel, 310S has better creep strength, can continuously work under high temperature, good heat resistance. If the pure heat is not more than 1300 is OK, but if want to heat processing the rolling deformation cannot exceed this temperature, the heating time is not short not long

- Q:Can stainless steel sheets be used for decorative ceiling tiles?

- Indeed, decorative ceiling tiles can be created using stainless steel sheets. Renowned for its durability, resistance to corrosion, and aesthetic allure, stainless steel is a versatile material. It can be effortlessly tailored and fashioned into an assortment of designs, textures, and finishes, rendering it an exceptional option for decorative applications. By incorporating stainless steel ceiling tiles, any environment, be it residential, commercial, or industrial, can acquire a contemporary and polished appearance. Furthermore, stainless steel proves to be a practical choice in areas where cleanliness is of utmost importance, as it is facile to clean and maintain.

- Q:How do I prevent fingerprints or smudges on stainless steel sheets?

- To prevent fingerprints or smudges on stainless steel sheets, there are several easy steps you can follow: 1. Clean the surface regularly: Wiping the stainless steel sheets with a soft cloth or microfiber cloth on a regular basis can help prevent fingerprints and smudges from building up. 2. Use mild soap and water: Mix a few drops of mild dish soap with warm water, and dip the cloth into this solution. Gently wipe the stainless steel surface, following the grain, to remove any dirt or oil that may attract fingerprints. 3. Dry thoroughly: After cleaning, make sure to dry the stainless steel sheets thoroughly using a clean, dry cloth. This will help prevent water spots or streaks that can make the surface appear smudged. 4. Avoid abrasive cleaners or tools: Harsh chemicals, abrasive cleaners, or scrub brushes can damage the stainless steel finish, making it more prone to smudges and fingerprints. Stick to mild cleaning solutions and soft cloths to maintain the integrity of the surface. 5. Apply a stainless steel cleaner or polish: Using a stainless steel cleaner or polish can create a protective barrier on the surface, making it more resistant to fingerprints and smudges. Follow the instructions on the product and apply it with a clean cloth, following the grain of the stainless steel. 6. Use gloves: If you know that your hands tend to leave fingerprints easily, consider wearing gloves while handling stainless steel sheets. This can help prevent direct contact with the surface and minimize the chances of leaving smudges. By following these tips, you can maintain the cleanliness and shine of your stainless steel sheets, preventing fingerprints and smudges from detracting from their appearance.

- Q:What's the difference between galvanized steel and stainless steel?

- The corrosion resistance of stainless steel decreases with the increase of carbon content. Therefore, the carbon content of most stainless steel is lower, the maximum is not more than 1.2%, and the Wc (carbon content) of some steel is even lower than 0.03% (such as 00Cr12). The main alloying element in stainless steel is Cr (chromium), which is corrosion resistant only when the Cr content reaches a certain value. Therefore, stainless steel in general Cr (chromium) content of at least 10.5%. Stainless steel also contains Ni, Ti, Mn, N, Nb, Mo, Si and other elements.

- Q:How do you prevent crevice corrosion on stainless steel sheets?

- To prevent crevice corrosion on stainless steel sheets, there are several measures that can be taken: 1. Regular cleaning and maintenance: Keeping the stainless steel sheets clean and free from any contaminants is crucial in preventing crevice corrosion. Regular cleaning with mild detergent and water, followed by thorough rinsing and drying, helps remove any potential corrosive agents. 2. Avoiding accumulation of debris or moisture: It is important to ensure that there are no crevices or gaps where debris or moisture can accumulate. Regular inspection and maintenance can help identify and rectify any such areas. Additionally, maintaining good drainage systems and avoiding water pooling can help prevent the accumulation of moisture, which can contribute to crevice corrosion. 3. Applying protective coatings: Applying a protective coating on the stainless steel sheets can provide an additional barrier against crevice corrosion. There are various types of coatings available, such as paints, epoxy coatings, or specialized corrosion-resistant coatings specifically designed for stainless steel. 4. Using appropriate gaskets and sealants: When fastening or joining stainless steel sheets, it is important to use compatible gaskets and sealants. These should be resistant to corrosion and provide a barrier against moisture and contaminants. Silicone-based sealants or gaskets made from PTFE (polytetrafluoroethylene) are commonly used for this purpose. 5. Preventing galvanic corrosion: Galvanic corrosion can occur when dissimilar metals come into contact with each other in the presence of an electrolyte, leading to corrosion of the less noble metal. To prevent this, it is important to avoid using dissimilar metals in close proximity to stainless steel sheets. If it is necessary to use dissimilar metals, insulating materials or coatings can be used to separate them. 6. Regular inspection and maintenance: Regularly inspecting the stainless steel sheets for any signs of corrosion and addressing them promptly is essential in preventing crevice corrosion. This includes checking for any signs of pitting, discoloration, or degradation of the protective coatings. Any identified issues should be addressed immediately to prevent further corrosion. By following these preventive measures, crevice corrosion on stainless steel sheets can be effectively minimized, ensuring their longevity and maintaining their aesthetic appeal.

- Q:Stainless steel sheet welding method, thickness of 0.5mm

- The matrix current, peak current, pulse frequency and pulse width are selected according to the rated output current parameters of the welding machine.

- Q:Can stainless steel sheets be used for architectural railings?

- Yes, stainless steel sheets can be used for architectural railings. Stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, making it a popular choice for architectural applications such as railings. It offers strength and stability while also adding a sleek and modern look to any structure.

- Q:Are stainless steel sheets resistant to scratches?

- Yes, stainless steel sheets are generally resistant to scratches. Stainless steel is known for its durability and strength, making it highly resistant to scratching or denting. However, it's important to note that no material is completely scratch-proof, and stainless steel can still develop minor scratches over time with regular use. However, these scratches are usually superficial and can often be easily removed or minimized with proper cleaning and maintenance. Additionally, the level of scratch resistance can vary depending on the grade and finish of the stainless steel sheet.

- Q:Can stainless steel sheets be used for outdoor applications?

- Certainly, outdoor applications can utilize stainless steel sheets. Due to its exceptional resistance to corrosion, stainless steel emerges as an ideal material for outdoor use. It can endure exposure to moisture, saltwater, and harsh weather conditions without succumbing to rust or deterioration. Outdoor structures like fences, handrails, roofs, and cladding regularly employ stainless steel sheets. Furthermore, outdoor appliances, equipment, and decorative elements also benefit from their utilization. Moreover, stainless steel sheets can be painted or coated to amplify their resistance against outdoor elements and match desired aesthetics. In summary, stainless steel sheets prove to be a robust and dependable option for outdoor applications.

- Q:Can stainless steel sheets be used for flooring?

- Certainly, flooring can indeed be made using stainless steel sheets. Stainless steel, being a sturdy and adaptable substance, possesses resistance against corrosion, stains, and scratches, thereby rendering it fitting for areas with heavy foot traffic. It is frequently employed in commercial and industrial environments like hospitals, kitchens, and food processing plants, where cleanliness and hygiene hold paramount importance. Stainless steel flooring imparts a polished and contemporary appearance, is effortless to clean and maintain, and can endure substantial loads and extreme temperatures. Furthermore, stainless steel sheets can be personalized to suit any area and can be installed with different finishes to augment slip resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolled Stainless Steel Coils,Stainless Steel Sheets Grade 304L NO.2B Finish Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords