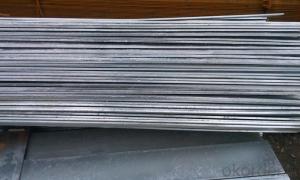

Cold drawn steel flat bar ; flat steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Commodity: Carbon Steel Flat Bar

Standard: GB, JIS, ASTM,

Material: Q235, SS400 or Equivalent

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Physical properties

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

Above sheets show the technical data of Q235,we can also provide other materials similar to Q235.

Usage/Applications

Widely used for construction;

Machinery manufacturing;

Iron tower steel structure;

Shipbuilding; Steel grating;

Staircase;

Bridge;

Viaduct;

Railway spare parts;

Boilers making etc.

Packaging & Delivery

Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

Production

The Carbon Steel Flat Bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

- Q:How do you use a steel square to lay out a diagonal line on a curved surface?

- To use a steel square to lay out a diagonal line on a curved surface, first, locate the desired starting and ending points of the diagonal line on the curved surface. Then, place the steel square on the curved surface, aligning one edge of the square with the starting point and the other edge with the ending point. Next, draw a line along the edge of the square to mark the diagonal line on the curved surface. Finally, use a flexible curve ruler or a flexible measuring tape to connect the marked points and create the diagonal line on the curved surface.

- Q:What are some common applications for a steel square in deck construction?

- Some common applications for a steel square in deck construction include measuring and marking angles, determining squareness of corners, checking for level and plumb, and assisting in cutting and laying out boards.

- Q:How do you use a steel square for making precise 45-degree angle cuts?

- To use a steel square for making precise 45-degree angle cuts, first, align one side of the square with the edge of the material you want to cut. Then, rotate the square until the 45-degree angle mark lines up with the edge of the material. Finally, use a pencil or a marking tool to trace along the edge of the square, ensuring a precise 45-degree angle cut.

- Q:How do you use a steel square for creating accurate rabbet cuts?

- For achieving precise rabbet cuts, the following steps should be followed while utilizing a steel square: 1. Begin by measuring and marking the dimensions of the desired rabbet cut on the wooden surface, which includes both the width and depth of the rabbet. 2. Align one side of the steel square with the wooden edge, ensuring it is placed accurately on the wood. 3. While firmly holding the steel square in place with one hand, employ a pencil or marking knife to trace along the other side of the square. This will generate a straight and precise guideline for the rabbet cut. 4. Proceed to repeat this procedure on the adjacent side of the wood, employing the same measurement and aligning the square with the previously marked line. This will ensure parallelism and precision in the rabbet cut. 5. Utilize a chisel, router, or table saw to eliminate the material within the marked lines, following the straight guideline established by the steel square. It is crucial to take your time and make accurate cuts to accomplish a clean and precise rabbet. 6. Once the rabbet cut is completed, utilize the steel square once more to verify squareness and guarantee that the corners of the rabbet are at perfect right angles. By utilizing a steel square as a reference guide, accuracy and precision can be maintained in your rabbet cuts, ultimately resulting in well-executed and professional-looking woodworking projects.

- Q:How do you use a steel square to measure board widths at different points?

- To use a steel square to measure board widths at different points, place the square's long side against the edge of the board and ensure it is perpendicular to the surface. Then, slide the square along the board, aligning it with different points where you want to measure the width. This will give you accurate measurements at each point along the board.

- Q:How do you use a steel square to ensure the correct angle for a mortise and tenon joint?

- To ensure the correct angle for a mortise and tenon joint using a steel square, you can follow these steps: 1. Start by marking the desired angle on the workpiece. This can be done by using a protractor or by referencing another piece with the desired angle. 2. Place the steel square against the edge of the workpiece, aligning one side of the square with the marked angle. 3. Hold the square firmly in place and use a pencil or marking knife to trace along the other side of the square. 4. Repeat this process on both the mortise and tenon pieces to ensure accurate alignment. By using a steel square in this manner, you can ensure that the angle for your mortise and tenon joint is correct, resulting in a strong and precise connection.

- Q:How do you maintain and care for a steel square?

- To effectively maintain and care for a steel square, there are several steps that can be taken: 1. Regular cleaning is essential: After each use, it is important to ensure that any debris, dust, or moisture is removed from the steel square. This can be accomplished by using either a brush or a cloth to wipe it down, guaranteeing its cleanliness and freedom from dirt or grime. 2. Lubrication of the moving parts is crucial: Steel squares often contain sliding parts that require smooth movement. To ensure their proper functioning, a small amount of lubricant should be applied to these areas. It is important to select a lubricant that is specifically designed for metal surfaces. 3. Proper storage is key: When the steel square is not in use, it should be stored in a dry and clean location. It is essential to avoid exposing it to extreme temperatures or humidity, as this can result in corrosion or damage to the metal. 4. Regularly inspect for rust: It is advisable to frequently examine the steel square for any indications of rust. If any rust spots are noticed, they should be gently cleaned using a wire brush or steel wool. Following this, a rust inhibitor or a light coat of oil should be applied to prevent further rusting. 5. Be cautious to prevent dropping or mishandling: Although steel squares are durable, they can still sustain damage if mishandled or dropped. It is important to exercise caution when using and storing them, in order to avoid any accidental harm. 6. Calibration is essential: Over time, it is possible for the measurements on a steel square to become inaccurate. To ensure its precision, periodic checks of its accuracy using a reliable measuring tool are recommended. If any adjustments are required, it is advisable to follow the manufacturer's instructions or seek professional assistance. By adhering to these steps, it is possible to effectively maintain and care for a steel square, thereby prolonging its lifespan and ensuring its accuracy for various tasks and projects.

- Q:Can a steel square be used for woodworking?

- Yes, a steel square can be used for woodworking.

- Q:How do you use a steel square to measure the height of a cabinet?

- To measure the height of a cabinet using a steel square, first make sure the cabinet is placed on a level surface. Then, position the steel square vertically against the side of the cabinet, aligning the long edge of the square with the top edge of the cabinet. The square should be flush against the cabinet and perpendicular to the surface it is resting on. Next, take a measuring tape or ruler and measure the distance from the bottom edge of the steel square to the floor or the surface the cabinet is resting on. This measurement will give you the height of the cabinet. To ensure an accurate reading, keep the steel square steady and straight against the side of the cabinet throughout the measurement process. For double-checking and accuracy, repeat the process on the other side of the cabinet. By utilizing a steel square, you can obtain a reliable and precise method for determining the vertical dimensions of a cabinet.

- Q:Can a steel square be used for plumbing and pipefitting?

- Certainly! A steel square, which is also referred to as a carpenter's square or a framing square, possesses the versatility required for plumbing and pipefitting tasks. This tool enables the measurement and marking of angles, the assessment of squareness, and the achievement of precise cuts and joints. In the realm of plumbing and pipefitting, a steel square serves the purpose of measuring and aligning pipes, executing meticulous cuts, and ensuring the appropriate angles and squareness in fittings and connections. Additionally, it proves valuable in establishing reference points and facilitating the proper installation of pipes and fixtures. Nevertheless, it is crucial to acknowledge that for more specialized plumbing and pipefitting endeavors, alternate tools specifically tailored for those tasks may prove more suitable and accurate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold drawn steel flat bar ; flat steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords