Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 45000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C:

OKorder is offering high quality Slit Cutting Flat Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Applications of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C:

Slit Cutting Flat Bars are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Advantages of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C:

OKorder's Slit Cutting Flats Barare durable, strong, and resist corrosion.

Main Product Features of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C:

Manufacture: Slit Cutting

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

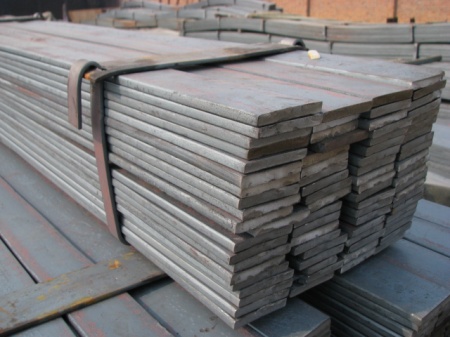

Images of Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C

I

- Q:Are steel flat bars available in metric sizes?

- Yes, steel flat bars are available in metric sizes. Metric sizes refer to the measurement system used in most countries outside of the United States, which is based on the International System of Units (SI). Steel flat bars can be found in various metric sizes, such as millimeters (mm) or centimeters (cm), to cater to the needs of different industries and applications. These metric sizes are commonly used in construction, manufacturing, and engineering projects where precise measurements are required. Overall, steel flat bars are available in both imperial and metric sizes to accommodate the diverse needs of customers worldwide.

- Q:Can steel flat bars be used for support beams or columns?

- Yes, steel flat bars can be used for support beams or columns. Steel flat bars are often used in construction because of their strength and durability. They can provide structural support and stability to a building or structure. However, it is important to consider the specific requirements and load-bearing capabilities of the project before using steel flat bars for support beams or columns. It is recommended to consult with a structural engineer or a professional in the field of construction to ensure that the steel flat bars are suitable for the intended purpose and meet the necessary safety standards.

- Q:How do steel flat bars perform in terms of UV resistance?

- Steel flat bars do not have good UV resistance.

- Q:Are steel flat bars suitable for making frames or supports?

- Yes, steel flat bars are suitable for making frames or supports. They are known for their strength, durability, and stability, making them an ideal choice for constructing frames and supports that require structural integrity and load-bearing capabilities. Additionally, steel flat bars can be easily welded or bolted together, providing flexibility in design and construction.

- Q:Can steel flat bars be galvanized for added protection?

- Yes, steel flat bars can be galvanized for added protection. Galvanizing is a process of applying a protective zinc coating to steel to prevent corrosion, thereby enhancing its durability and lifespan.

- Q:How many steel tubes can be used instead of 60 * 10 flat steel?

- Stainless steel pipe can be divided into stainless steel seamless steel pipe and stainless steel welded pipe (seamed pipe) two kinds of NO.320 stainless steel plate fine grinding NO.2D and NO.2B material, grinding of stainless steel 301 - good ductility with 320# abrasives abrasive belt, used for molding products.

- Q:How is a steel flat bar made?

- A steel flat bar is typically made through a process called hot rolling. The process begins with heating a large steel billet or slab to a high temperature, typically around 1200 to 1300 degrees Celsius. The heated billet is then passed through a series of rolling mills, where it is gradually flattened and shaped into a long, thin strip known as a flat bar. In each rolling mill, the steel billet is passed through a pair of rotating rolls, which exert pressure on the billet and gradually reduce its thickness. The billet is rolled multiple times, with the gap between the rolls getting smaller with each pass. This continuous rolling process helps to refine the grain structure of the steel, improving its strength and durability. After the desired thickness is achieved, the flat bar may undergo additional processes such as cooling, straightening, and cutting to the required length. Cooling is typically done using air or water to rapidly cool the steel and lock in its desired properties. Straightening helps to remove any bends or twists that may have occurred during the rolling process, ensuring a uniform flat shape. Once the flat bar is cooled and straightened, it is cut into individual lengths using shearing or sawing machines. These lengths can then be further processed or used as is for various applications. Overall, the production of a steel flat bar involves heating a steel billet, hot rolling it through a series of rolling mills to achieve the desired thickness, cooling, straightening, and finally cutting it into individual lengths. This process results in a versatile and widely used product that finds applications in industries such as construction, manufacturing, and automotive.

- Q:Can steel flat bars be used in construction projects?

- Construction projects can indeed utilize steel flat bars. These bars, known for their strength and durability, find widespread use in various construction applications. They commonly feature in the construction of buildings, bridges, highways, and other infrastructure projects. As structural support elements, steel flat bars are often found in beams, columns, and braces, capable of withstanding heavy loads and resisting bending. Their versatility extends to reinforcement in concrete structures like slabs and foundations, effectively bolstering the overall strength and stability of the construction. Moreover, steel flat bars can be easily welded, bent, and fabricated to meet specific project requirements, rendering them a sought-after choice in construction.

- Q:Does the cable trench need grounding?

- The cable trench needs grounding.

- Q:What are the different types of surface coatings available for steel flat bars?

- Steel flat bars can be coated with various types of surface coatings, each offering its own advantages and characteristics. 1. Galvanized Coating: Applying a layer of zinc to the steel flat bar surface is a commonly used coating. This coating provides excellent protection against corrosion and environmental factors, preventing rust. 2. Powder Coating: In this process, a dry powder is applied to the steel flat bar and then heated to create a durable coating. Powder coating is popular for both decorative and protective purposes due to its wide range of colors and finishes. 3. Epoxy Coating: Known for its strong adhesion and chemical resistance, epoxy coatings create a tough and durable layer on the steel flat bar. This makes them suitable for industrial applications in harsh environments. 4. Paint Coating: A cost-effective option for protecting steel flat bars, paint coatings come in various colors and finishes. They provide both aesthetic appeal and corrosion protection. 5. Anodized Coating: While commonly used on aluminum, anodizing can also be applied to steel flat bars. This process creates an oxide layer that enhances corrosion resistance and improves the appearance of the steel. 6. Chrome Plating: By depositing a layer of chromium onto the steel flat bar surface, chrome plating offers excellent hardness, wear resistance, and a polished appearance. 7. Phosphate Coating: Often used as a pre-treatment before painting or powder coating, phosphate coatings enhance the adhesion of subsequent coatings and provide additional corrosion resistance. When choosing the appropriate surface coating for steel flat bars, it is important to consider the specific requirements of your application. Factors such as corrosion resistance, durability, aesthetics, and cost should be taken into account to ensure the best choice for your needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Drawn Carbon Steel Flat Bar S45C & 4140 & 5140 & 20CrMnTi & S20C

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 45000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords