Coil Reasonable Rebar Price Tying Wire for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Coil Reasonable Rebar Price Tying Wire for Construction

Description for Coil Rebar

Type | Rebar coil and wire rod |

Steel Grade | HRB400 , HRB500, GR.60, Q235, Q255, Q275, SAE1006, SAE1008 |

Your required chemical composition. | |

Size | 5.5mm-10mm |

Unit weight | 1.6-1.9 Tons/coil |

Application | Building/project construction |

Packing | In coil with steel strip ,in bulk . |

MOQ | 1000tons(500for trial order ). |

Delivery Time | 25days . |

Payment | T/T , West Union , Cash , L/C. |

Trade Terms | FOB, CFR, CIF ,EXW |

Trans terms | FIO FILO FLT |

Loading port | Caofeidian /Jingtang/Tianjin,China |

Datas of Chemical Composition for Coil Rebar

Content | C% | Mn% | Si% | Cr% | Ni% | S% | P% | Cr% |

HRB400 | 0.14-0.22 | 0.40-0.65 | 0.05-0.15 | 0.30max | 0.30max | 0.050 | 0.040 | 0.30min |

HRB400E | 0.14-0.22 | 0.40-0.65 | 0.15-0.30 | 0.30max | 0.30max | 0.050 | 0.040 | 0.30min |

HRB500 | 0.28-0.37 | 0.50-1.00 | 0.05-0.15 | 0.30max | 0.30max | 0.050 | 0.040 | 0.30min |

HRB500E | 0.28-0.37 | 0.50-1.00 | 0.15-0.30 | 0.30max | 0.30max | 0.050 | 0.040 | 0.30min |

FAQ

Why Should You Choose Us:

Stable quality ----continous casting hot rolled production techenic, strictly quality control system.

Lower price -------Not the cheapest but the lowest price at the same quality .

Good service -----Satisfactory service within 24hours.

Delivery time ------15-25days for the mass production .

Discount---------------discount base on monthly large quantity purchase in long term.

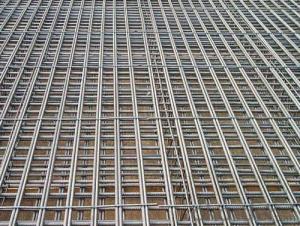

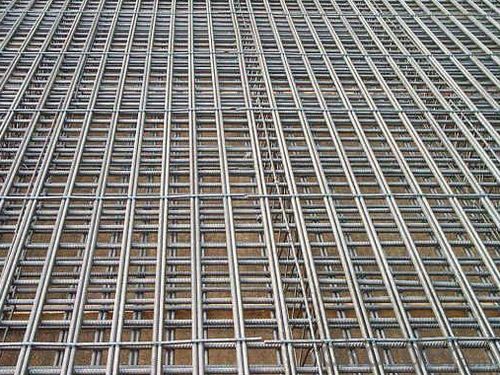

Picture:

- Q:Is there any cast iron pipe used in the fire hose?

- I do not know, are generally seamless steel pipe or spiral pipe, straight seam pipe.

- Q:Can ductile iron pipe be used for underground storage tank systems?

- Yes, ductile iron pipe can be used for underground storage tank systems. Ductile iron is a strong and durable material that is resistant to corrosion and can withstand the pressure and load requirements of underground storage systems.

- Q:Can ductile iron pipes be used for water distribution networks?

- Yes, ductile iron pipes can be used for water distribution networks. Ductile iron is a type of cast iron that has enhanced flexibility and strength, making it suitable for various applications, including water distribution systems. Ductile iron pipes have been widely used in water supply networks due to their durability, corrosion resistance, and long lifespan. They can withstand high pressure and are resistant to external loads and ground movement, which makes them ideal for underground installations. Ductile iron pipes are also commonly used for transporting potable water as they are non-toxic and do not contaminate the water supply. Furthermore, ductile iron pipes have excellent hydraulic properties, ensuring efficient water flow and minimizing friction losses. Their smooth interior surface helps to prevent the buildup of deposits, reducing the risk of clogging and maintaining a consistent water flow. Overall, ductile iron pipes provide an effective and reliable solution for water distribution networks, ensuring the safe and efficient transportation of water to communities and industries.

- Q:Can ductile iron pipes be used for geothermal energy systems?

- Certainly, geothermal energy systems can utilize ductile iron pipes. Ductile iron, being a robust and long-lasting substance, possesses the capacity to endure the frequently encountered elevated temperatures and pressures in geothermal energy systems. Its ability to resist corrosion and exhibit high tensile strength renders it a perfect selection for conveying geothermal fluids. Furthermore, the ease of joining ductile iron pipes permits flexibility and adaptability during the design and installation phases. All in all, ductile iron pipes prove to be a trustworthy and economically viable alternative for geothermal energy systems.

- Q:The plug connection DN800 ductile iron pipe has been installed. "Shall I think so?"

- In many areas of our country, ductile iron pipe in the middle and small diameter to tube connected with the tube, the bearing type or flange interface method; ductile iron, angle limit must be allowed better seismic performance and sealing performance.

- Q:How are ductile iron pipes protected against external corrosion?

- Ductile iron pipes are protected against external corrosion through the application of protective coatings such as polyethylene, epoxy, or zinc. These coatings act as a barrier between the pipe and the surrounding environment, preventing contact with corrosive elements such as water, soil, or chemicals. Additionally, cathodic protection techniques, such as sacrificial anodes or impressed current systems, may also be employed to further enhance the corrosion resistance of ductile iron pipes.

- Q:Are ductile iron pipes suitable for high-temperature applications?

- Ductile iron pipes are generally not suitable for high-temperature applications. While ductile iron is known for its strength and durability, it has limitations when it comes to high temperatures. Ductile iron pipes are typically rated for a maximum operating temperature of around 250-300 degrees Fahrenheit (120-150 degrees Celsius). At higher temperatures, ductile iron pipes can experience thermal expansion, which may lead to cracking or distortion. This can compromise the structural integrity of the pipe and potentially cause leaks or failures. Additionally, ductile iron is susceptible to oxidation at elevated temperatures, which can further degrade the pipe's performance over time. For high-temperature applications, it is generally recommended to use materials specifically designed for such conditions, such as stainless steel or high-temperature alloys. These materials offer better resistance to thermal expansion, oxidation, and other factors associated with high temperatures.

- Q:What pipe can be used to replace the cast iron pipe in the water supply? Thank you

- Cast iron pipes (Cast, Iron, Pipe), cast cast pipe. Cast iron pipes are used for water supply, drainage and gas transmission lines. They include cast iron pipes and pipe fittings. Labor intensity is small.

- Q:How can the ductile iron pipe elbow be fixed?

- The groove connecting pipe consists of two categories of products: sealing function of pipe connections with rigid joint, flexible joint, mechanical three and groove flange; the pipe connections transition of elbow, three links, four links, different diameter pipe, blind plate etc..

- Q:Do ductile iron pipes have inner enamel?

- If the market supply is indeed difficult, can be done by the owners, Design Institute of supplier relationship; if the design institute requires it to provide products can persist in wilfully and arbitrarily, the available information (if the market can not supply, design a hair ah).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coil Reasonable Rebar Price Tying Wire for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords