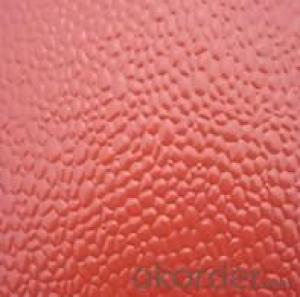

Coated Stucco Aluminium Sheet-AA1XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1 Specifications of PE Coated Aluminum Coil/Sheet

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-4.0mm |

Width: | 10mm- 2000mm |

Coating | PE(Polyester) |

Painting Thickness | Standard 16-25 microns, max 40 microns |

Color | Acording to Ral colors or customer’s samples |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

PE(polyester) Coating

PE(polyester) coating:high molecular polymer as monomer and addition of alkyd, is an UV-resistant coating. It can be classified matt and glossy according to coating gloss. The compact molecule structure, makes paint surface luster and smooth,which assure good printing on the panel surface. With an warranty of 8-10 years for weather resistance, it is specially applied for internal decoration and sign board.

2 Usage/Applications of PE Coated Aluminum Coil/Sheet

Our company's PE Coated Aluminum Coil/Sheet have been widely used in the fields of construction and decoration(garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipe, sanwich panels and drainage, etc.

- Q:Can aluminum sheet be used for automotive heat shields?

- Yes, aluminum sheet can be used for automotive heat shields. Aluminum is a popular choice for heat shields in the automotive industry due to its excellent thermal conductivity and high heat resistance. It helps to protect sensitive components from excessive heat by reflecting and dissipating the heat away from the desired areas. Additionally, aluminum is lightweight and corrosion-resistant, making it an ideal material for automotive applications. It is commonly used in various heat shield designs, including exhaust heat shields, engine heat shields, and under-carriage heat shields.

- Q:Over the years, the thermite reaction has been used for welding railroad rails, in incendiary bombs, and to ignite solid-fuel rocket motors. The reaction is given below.Fe2O3(s) + 2 Al(s) 2 Fe(l) + Al2O3(s)What masses of iron(III) oxide and aluminum must be used to produce 10.0 g iron?a) iron (III) oxideb)aluminiumc)What is the maximum mass of aluminum oxide that could be produced?

- i'm uncertain regardless of the incontrovertible fact that it must be relaxing, are you making thermite? i might guess which you would be able to artwork this out from the atomic weights of each, and taking the valencies under consideration - 2 aluminium atoms for 3 oxygen atoms. 2 iron atoms for 2 oxygen (a million:a million).

- Q:What are the different methods of surface engraving aluminum sheets?

- Aluminum sheets can be surface engraved using various methods, each with its own unique advantages and suitability for different applications. One method is mechanical engraving, which involves physically removing material from the aluminum sheet using a rotating cutting tool like a milling machine or a router. This precise and versatile technique allows for intricate designs and deep engravings, making it commonly used for signage, branding, and decorative purposes. Another method is laser engraving, a modern and highly precise technique that uses a laser beam to vaporize or melt the surface of the aluminum sheet, creating a permanent mark. With great control over the depth, speed, and intensity of the engraving, laser engraving produces detailed and accurate results. It finds wide application in industries like aerospace, automotive, and electronics for part identification, serial numbers, and barcodes. Chemical etching, also known as chemical milling or photochemical machining, is a process where the aluminum sheet is coated with a photosensitive mask and exposed to UV light through a stencil or artwork. The exposed areas are then chemically etched to create the desired design. Chemical etching offers high precision, repeatability, and the ability to engrave thin lines or complex patterns. It is often used in electronic components, nameplates, and decorative applications. Diamond drag engraving involves using a diamond-tipped stylus to scratch or indent the surface of the aluminum sheet, creating the engraving. This method is commonly employed for industrial applications like part identification and serial numbering, as well as for creating durable and long-lasting markings on aluminum sheets. Lastly, rotary engraving utilizes a rotating cutting tool to remove material from the aluminum sheet, similar to mechanical engraving. However, it is typically used for larger and thicker aluminum sheets and finds application in industrial settings for marking, labeling, and identification purposes. Choosing the appropriate engraving method for aluminum sheets depends on factors such as the desired design, level of detail, durability requirements, and the intended use of the engraved product. Each method offers its own advantages and suitability for different applications.

- Q:Are aluminum sheets suitable for electrical connectors?

- Indeed, electrical connectors can be effectively made using aluminum sheets. Aluminium, being a metal with high conductivity, is an ideal option for facilitating the flow of electric current. Its low electrical resistance enables the efficient transmission of electricity. Moreover, aluminum is renowned for its lightweight properties, resistance to corrosion, and affordability, rendering it a favored choice for electrical connectors across diverse sectors like automotive, aerospace, and electronics. Nevertheless, it should be emphasized that when aluminum connectors are utilized alongside dissimilar metals, extra precautions might be necessary to avert the occurrence of galvanic corrosion.

- Q:i need to know these things please....can aluminium withstand the forces of being in a cargo hold on a air freight, can it withstand extreme temps and to what extent an is it microwavable?? please help me

- No metals are microwavable, they will ruin any microwave oven by producing sparks. Even ceramic plates with a little metallic paint eg of silver will spark. Aluminium on its own has little strength but when mixed with small amounts of eg copper or manganese it aquires great strength while remaining light. In addition it has the advantage of being very resistant to oxidation and corrosion. It is certainly used extensively in aircraft construction. Due to being non toxic it used to make cans for beers, soft drinks (sodas) etc However it doesn't stand up well to high temperatures, its melting point is just at 660 degrees celsius, by comparison for iron it is 1540 and tungsten 3420.

- Q:Can the aluminum sheets be bent or formed into different shapes?

- Aluminum sheets possess the remarkable ability to undergo effortless bending and shaping procedures. Displaying exceptional malleability, aluminum is capable of being manipulated with utmost ease, devoid of any risk of fracturing or shattering. This unique characteristic renders it a perfect choice for diverse applications that necessitate adaptability and tailored specifications. Employing an assortment of methodologies including press brakes, rollers, and specialized forming tools, aluminum sheets can be flexed, folded, rolled, or formed effortlessly. Such remarkable versatility enables the fabrication of intricate shapes and structures, rendering aluminum an immensely favored option in sectors like construction, automotive, aerospace, and manufacturing.

- Q:Can aluminum sheet be used for decorative purposes?

- Yes, aluminum sheet can be used for decorative purposes. Its lightweight nature, durability, and versatility make it a popular choice for various decorative applications such as signage, wall cladding, ceiling panels, furniture accents, and more. Additionally, aluminum sheets can be easily manipulated, painted, or coated to achieve different finishes, colors, and textures, allowing for endless possibilities in decorative design.

- Q:What are the safety precautions when working with aluminum sheets?

- When working with aluminum sheets, some important safety precautions to consider include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to protect against cuts, eye injuries, and inhalation of aluminum dust. It is crucial to work in a well-ventilated area or use local exhaust ventilation to minimize exposure to dust and fumes. Additionally, ensuring that the work area is clean and free of clutter can help prevent slips, trips, and falls. Finally, it is essential to handle aluminum sheets with care to avoid sharp edges and to prevent heavy sheets from falling or causing injury.

- Q:Can aluminum sheets be used for outdoor applications?

- Certainly, outdoor applications can involve the utilization of aluminum sheets. Aluminum, being both resilient and resistant to corrosion, proves itself suitable for a diverse array of outdoor purposes. It is frequently employed in tasks such as roofing, siding, guttering, as well as outdoor signage. A distinguishing feature of aluminum sheets is their exceptional strength-to-weight ratio, rendering them perfect for situations where a material that is simultaneously lightweight and robust is imperative. Moreover, aluminum possesses the inherent ability to generate a safeguarding oxide layer, thereby shielding itself from external elements. Consequently, it emerges as a dependable option for outdoor settings.

- Q:Are aluminum sheets suitable for chemical processing applications?

- Yes, aluminum sheets are suitable for chemical processing applications. Aluminum is known for its excellent corrosion resistance, making it a popular choice in various chemical industries. It can withstand exposure to many chemicals, including acids, alkalis, and organic solvents. Additionally, aluminum sheets are lightweight, easy to work with, and offer good thermal conductivity, making them versatile and efficient for chemical processing applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coated Stucco Aluminium Sheet-AA1XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords