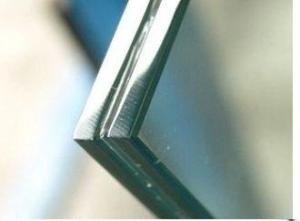

Coated laminated glass 8+1.14pvb+8+15A+8 Color glass windows glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q:Sorry if this is a really stupid question, please go easy on me.Tell me if this is possible or not:An aviary that in 10m or more long in length which houses smaller species of birds. Part of the aviary is against the house and a window. The window is tinted so that the birds don't think that they can fly through it (but would the reflection still be a problem?). But people in the room can see through the window and the birds in the aviary.Possible or bad idea? Any alternatives? I have seen entire aviaries made out of acrylic and see-through, and also a restaurant with a massive aviary the size of the wall behind glass, I just wonder how they do it without birds breaking their necks on the glass.

- What we did with our aviary (home grown built as well) was put a layer of screened mesh (like you use for patio screens) over the acrylic windows. It helps to dim the glare and prevents the birds from running into them. It's cheap and you can buy it in rolls. Just staple it to the wood around the frame of your windows.

- Q:What parts of the building curtain wall project?

- Building curtain wall is the building does not bear the external wall of the Wai, usually by the panel (glass, metal plate, slate, ceramic plate, etc.) and the back of the support structure (aluminum beam column, steel structure, glass ribs, etc.).

- Q:I want to build a small soundproof glass room in my living room, since i have another family member moving in and it will be hard to talk over the phone at night and listen to music, since I already share my room. I picture it as big as a phone booth but just longer some how so I can lay in it and just talk on the phone or use my laptop. I have no idea what company I should search for to build a glass soundproof room that small. or maybe it can be about 10 feet by 5 feet. No matter if its sliding door or not. Any info would help me. Thanks Even personal stories on other kinds of soundproofing that works thats affordable.

- Build A Soundproof Room

- Q:Find the role of several new glass features, to concentrate a little Hurry Short point, a little concentration, tomorrow to use acridine!

- Safety glass is compared with ordinary glass, with high mechanical strength, impact resistance of the glass. Its main varieties are tempered glass, laminated glass, laminated glass and titaniumized glass. Safety glass is crushed, the debris will not hurt, and both anti-theft, fire function. According to the production of glass used in the original film does not, safety glass has a certain decorative effect.

- Q:What is the glass?

- Plexiglass. Tempered glass.

- Q:the usage of glass in building construction has been in constant increase in the past decade.these glasses would certainly increase the volume of reflection in the atmosphere..doesn't this add to the temperature rise ?

- A chalcogenide glass bolometer for detection of electromagnetic radiation wavelengths varying from infrared to microwave. The radiation absorbed by the glass increases its electrical conductivity, enabling measurement of the radiation. A method of fabricating the bolometer is also disclosed

- Q:Not man-made destruction of tempered glass why suddenly broken

- Tempered glass has bleed characteristics This is because the glass raw materials containing nickel sulfide crystals, is the world's existing manufacturing technology can not be completely avoided, only through the purity of raw materials and processing technology to control the risk of a little lower blew. On the concept of self-blasting rate, our country only on the external walls of the engineering glass has a national standard, I do not know whether the foreign industry for the use of tempered glass also has detailed provisions. One ton of glass raw materials, there are at least 3-4 nickel sulfide crystals, this one ton of glass made of several square meters of the size of the glass, which will have 3-4 tablets blew, which is blew the image depicting.

- Q:Building glass film sales channels which

- Direct sales and distribution

- Q:What is the difference between home insulation film and car insulation film?

- Home reflective film point, good heat insulation, automotive reflective film can not be too much, otherwise the traffic police will let the tear

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coated laminated glass 8+1.14pvb+8+15A+8 Color glass windows glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords