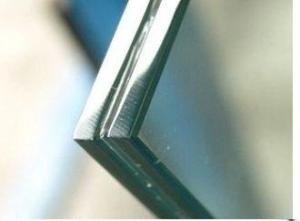

Coated laminated glass 8+1.14pvb+8+15A+8 Color glass Hollow glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q:How much would it cost to build a 15 foot glass wall that is 1 inch thick and 8 feet in heigh

- I suggest you contact your local glass merchant. I am not being rude but you need more than dimensions to give you an answer. 1, First where do you live. The price in New York is likely to be different than the price in Juneau, Alaska (or in Chiang Mai Thailand where I live!) 2. Do you need a single piece of glass or a lot of smaller panes 3. What specifications for any joints? 4. Do you want the price of construction included or will you do it yourself? 5. Do you want the materials delivered or will you pick them up. 6. What about cost of transport / shipment? I hope you understand what I am getting at. There are too many factors for anyone on here to be able to help you. Therefore contact a local glass dealer and give him/her your EXACT requiremernts and they will give you the only meaningful answer that you will get.

- Q:Glass insulation film how to tear off

- With a hair dryer while blowing side of the tear, this should be able to!

- Q:What brand of hot-melt glass is better?

- can! Rewan glass is made of flat glass (with float glass) for secondary processing. The float glass is a substrate that can be used to process tempered glass!

- Q:Can acrylic panels do roofing materials?

- Hello, what is acrylic? Acrylic (ACRYLIC) new three-dimensional material luminous word is a special plexiglass. Because of its excellent strength and good light transmission, early was used to make aircraft windshield and tank view mirror. Modern acrylic material coated with a high-intensity UV absorber and has a rich and colorful color, colorful night and highly penetrating, anti-sun and rain, the service life of up to ten years, is the most popular in the world Outdoor logo signs one of the manufacturing materials. In Paris, New York, Tokyo and other international metropolis of the bustling business district, everywhere visible acrylic logo products of the beautiful figure, for many internationally renowned corporate brand image to add infinite charm. In China, the use of acrylic logo products is still the initial stage, but with McDonald's, Kentucky and other well-known international companies demonstration use, in OKorder and other places in OKorder have more and more enterprises love to use acrylic as panel material Built-in light source identification products.

- Q:Glass for building construction mainly.

- The first known attempt to make glass in Canada began in 1819, when a German-born American entrepreneur worked for a year to establish a glass works at Rice Lake, Ontario, before his land grant was revoked and he abandoned the enterprise. The first recorded production of glass in Canada occurred in 1839 in the Mallorytown Glass Works, Ontario. Between 1840 and 1860, window glass and bottles were being made in five Canadian glass works in Quebec and Ontario. Window glass in Canada was first made in the 1850s in Quebec at the Canada Glass Works, Saint Jean, and the Ottawa Glass Works, Como. After 1880, new glass factories were established in Montreal, Wallaceburg (Ontario), and New Glasgow (Nova Scotia), with bottles, jars, and lamp chimneys their major products. By 1900, Canadian glass works were supplying about half of the Canadian market of 5.5 million people with bottles, lamps, and tableware. Most Canadian glass of this era consisted of pressed glass, machine-made glassware formed by pressure between a mechanically moving plunger and a mould. From 1839 to the present, glass works were established in forty-three Canadian communities from Nova Scotia to British Columbia. One of the largest was Dominion Glass with factories in Montreal, Toronto, Hamilton (Ontario), Wallaceburg, Winnipeg, Redcliff (Alberta), and Burnaby (British Columbia).

- Q:I'm drawing a building and a part of it cylindrical and all covered with colored glass sheets, and i don't know how to show all that together: that it's glass, colored and cylindrical, so if anyone has any idea I'd be thankful :)

- Shade that section as if it WERE a cylindar. Even glass panes look different in the shade than those sections that are in full sunlight. If your elevation is rendered in color, you can add gradiated touches of light blue to darker blue to indicate the curvature of the section. If it's black and white, then use greys. It it is strictly a line drawing then darker and more numerous streaks of black lines can create the shaded effect.

- Q:2680 Building glass visible light transmission ratio is invalid?

- Insulating glass is characterized by environmental protection with sound insulation and other advantages "dew point detection" is to test the airtight insulation to ensure that the air cavity is independent and stable drying "visible light transmission ratio" is for different design requirements need to use different insulating glass products Conducting different substrate transmittance is not the same as "shading coefficient" is for coated glass or.

- Q:Insulation paint, I want to do insulation paint, the home is too hot, smart glass insulation coating how?

- Adhesive insulation insulation film is the disadvantage of poor durability, low transmittance, the advantage is simple construction. Nano insulation coating is the disadvantage of the construction of a little trouble point (need to spray, professional operation), the advantage is good durability, high transmittance. This kind of paint I was some time ago to transform my store when used, the effect is surprisingly good. Nano-thermal insulation coating using advanced nano-technology, research and development production of high transparency, super insulation, high hardness, anti-glare of the "nano-level" functional oxide powder can be evenly dispersed in high weather resistance of the transparent resin base material, Synthesis of "nano-high permeability paint." And the glass surface is cured to a thickness of only 7-8um nano-film, taking into account the glass insulation performance and lighting performance, so that the whole glass truly become "nano-high permeability heat-saving glass." Energy-saving effect of architectural glass nano-modified energy-saving film made of architectural glass, compared with ordinary glass, about 40 ℃ in the sunlight, the enclosed space temperature difference of 5 ~ 11 ℃. Surely it is good to use nano thermal insulation coating.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coated laminated glass 8+1.14pvb+8+15A+8 Color glass Hollow glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords