Coated Aluminium Tape for Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

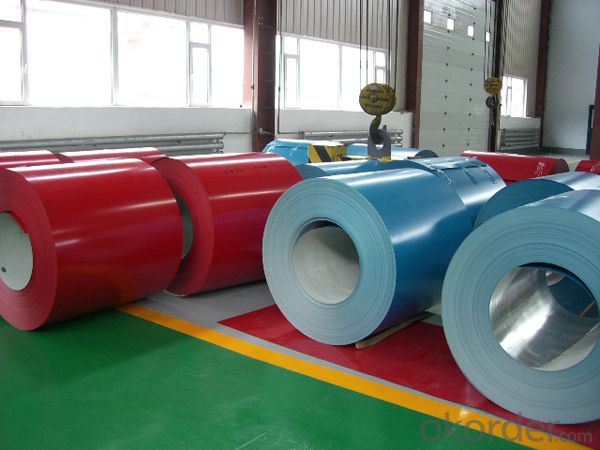

Coated Aluminium Tape for Aluminium Composite Panel

Description

Alloy | 1060, 1100, 3003, 8011, etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.05mm to 3.0mm |

Width | Standard width:1240mm |

Special width:1300mm, 1520mm, 1570mm, 1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, ACRYLIC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness(pencil resistance) | More than 2h |

Coating adhesion | 5J (EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility(T-bend) | 2T |

MEK resistance | More than 100 |

Advantage | 1.High temperature resistant 2.Weathering resistant 3.Scrubbing resistant 5.Acid or alkali proof 6. Fireproof 7.Light weight material is easy to construct and install |

Out package | Wooden splint with export standard |

Application | ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels, etc |

Manufacturing

Decoiler → Accumulator →Tension Leveler →Acid & Alkali Cleaner → Rinse →Conversion Treatment → Priming coater →Infrared Curing Oven →Main coater →Floatation Curing Oven →Strippable Film Applicator → Exit Accumulator → Recoiler

Polyester Coatings (PE)

PE (polyester) coatings exhibit an excellent combination of hardness, flexibility, flow, appearance, and superior resistance to dirt retention in indoor and outdoor applications. These coatings are highly resistant to abrasion, metal marking, staining, and marring, and require minimal maintenance. Glazetech uses polyester paints which provide excellent colour and gloss retention properties.

Polyvinylidene Fluoride Coatings (PVDF)

PVDF (polyvinylidene fluoride) is a chemical resistant thick film barrier coating commonly used in architectural applications where both excellent appearance and substrate protection must be maintained over a long period of time. This coating is unaffected by most chemicals and solvents and has excellent wear and abrasion resistance. PVDF also has a high dielectric strength, excellent resistance to weathering and the ability to self extinguish.

Application

Widely used in manufacturing of products as well as other industrial applications like:

Products Materials: PP cap stock, the traffic sign, air-conditioner heat and exchangers, food container, household foil, pharmaceutical packing, cigarettes packing etc.

Building Materials: aluminum curtain wall base plate, ACP, aluminum, ceilings, aluminum sheets, honeycomb panels and aluminum roofing, lighting decoration, household electrical appliances, food package (such as pop can cover & ring-pull), furniture ect.

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q:The box doesn't tell me. I need to know because my gun range won't allow steel or aluminum cartridges

- A magnet will tell if there is steel. Usually the concern is only for steel in the projectile, not the case. Indoor ranges are worried about damage to their back stop. Outdoor ranges may be concerned about starting fires due to sparks. If a range told me the cases could not be steel or aluminum, I would find another range. They probably want to keep the shells you leave on the ground, but don't want to have to separate the reloadable from the non-relaodable. That makes them bums.

- Q:Can aluminum coils be used for electrical transformers?

- Indeed, electrical transformers can utilize aluminum coils. The application of aluminum as a material for transformer coils is attributed to its superior electrical conductivity and cost-effectiveness in comparison to copper. Traditionally, copper has been favored for transformer windings; nevertheless, the utilization of aluminum has gained traction in recent times due to its lighter weight and more affordable price. Additionally, aluminum coils offer advantages in terms of thermal conductivity, as they efficiently dissipate heat in contrast to copper. Nevertheless, it is crucial to take into account the specific demands and design considerations of the transformer, as the decision between aluminum and copper coils may hinge upon factors such as voltage, current, size, and insulation requirements.

- Q:like i need a good slogan for aluminum its for a school project like for arsenic's is Arsenic's a sure fire way to deal with a rat, It works better than a mean old cat!

- Aluminum: Keeping stoners amazed for over 50 years!

- Q:How are aluminum coils protected against oxidation during storage?

- Aluminum coils are protected against oxidation during storage by applying a thin layer of protective coating or by storing them in a controlled environment, such as a dry and moisture-free area. This prevents exposure to oxygen and moisture, which are the main factors contributing to oxidation.

- Q:Are aluminum coils suitable for HVAC systems?

- Yes, aluminum coils are suitable for HVAC systems. They offer several advantages such as corrosion resistance, lightweight construction, and efficient heat transfer, making them a popular choice for cooling and heating applications in HVAC systems.

- Q:I heard that one pound of aluminum pop tabs are worth more then a pound of aluminum pop cans. Is this true? Thank you.

- I Think So Because clean aluminum is easier to handle because they don't have to wash it like unclean aluminum.

- Q:Do you have an aluminum coil first? Is there an aluminum plate?

- The general process of aluminum plate production is: aluminium ingot - aluminum water - casting roll - aluminum roll ---- aluminum plate [Ji'nan excellent aluminum industry]. Welcome to visit.

- Q:What are the different coil cutting options available for aluminum coils?

- Some of the different coil cutting options available for aluminum coils include slitting, shearing, and laser cutting.

- Q:Are aluminum coils suitable for architectural cladding?

- Yes, aluminum coils are suitable for architectural cladding. Aluminum is a lightweight and durable material that is often used in the construction industry for its versatility and aesthetic appeal. Aluminum coils can be easily formed into various shapes and sizes, making them ideal for architectural cladding applications. One of the key advantages of using aluminum coils for cladding is their resistance to corrosion. Aluminum naturally forms a protective oxide layer, which helps to prevent rusting and deterioration over time. This makes aluminum a long-lasting and low-maintenance option for architectural cladding. Additionally, aluminum coils offer a wide range of finishes and colors, allowing for greater design flexibility. They can be painted or coated to match any architectural style or design concept, making them a popular choice among architects and designers. Furthermore, aluminum is an environmentally friendly material. It is fully recyclable and has a much lower carbon footprint compared to other cladding materials like steel or concrete. This makes aluminum coils a sustainable choice for architectural projects. In summary, aluminum coils are indeed suitable for architectural cladding due to their durability, resistance to corrosion, design flexibility, and environmental benefits.

- Q:What are the different finishes available for aluminum coils?

- Aluminum coils offer a variety of finishes, each with its own unique properties and appearance. 1. The most basic and commonly used finish for aluminum coils is the mill finish. It showcases the natural appearance of aluminum without any additional treatment or coating. While it provides a smooth and shiny surface, it is not as resistant to corrosion as other finishes. 2. Anodized finishes, on the other hand, enhance the corrosion resistance and durability of aluminum through an electrochemical process. This creates a thick protective layer on the surface of the coil, making it highly resistant to weathering, scratches, and fading. Anodized finishes are available in different colors and can be customized to meet specific design requirements. 3. To achieve specific colors, textures, and levels of durability, aluminum coils can be painted with various types of coatings. These coatings are applied using a coil coating process, ensuring even distribution and curing onto the surface of the aluminum. Painted finishes offer excellent color retention and weather resistance, and can be tailored to suit individual project needs. 4. For a textured appearance, the surface of the aluminum coil can be mechanically brushed using abrasive materials. This creates a brushed finish, which not only provides a unique aesthetic appeal but also helps hide scratches and blemishes. Brushed finishes are commonly used in architectural applications like interior design, signage, and furniture. 5. Embossing involves imprinting patterns or designs onto the surface of the aluminum coil, resulting in an embossed finish. This adds texture and visual interest to the material, making it suitable for decorative purposes. Embossed finishes can mimic various textures, such as wood grain or stucco, and are widely used in building facades, roofing, and signage. 6. Laminating involves bonding a layer of protective film or sheet onto the surface of the aluminum coil. This laminated finish provides additional protection against scratches, stains, and UV rays. It is commonly used in applications that require high durability, such as transportation, appliances, and electronic enclosures. Ultimately, the choice of finish for aluminum coils depends on specific project requirements, including aesthetics, durability, and environmental factors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coated Aluminium Tape for Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords