Coated Aluminium Sheet Coated Aluminium Sheet AA6061 5054

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Coated Aluminium Sheet Coated Aluminium Sheet AA6061 5054 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Coated Aluminium Sheet Coated Aluminium Sheet AA6061 5054 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder'sCoated Aluminium Sheet Coated Aluminium Sheet AA6061 5054 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Aluminum sheet / plate

1) Alloy: 1050. 1060, 1100, 1070, 1200, 3003 5052 5754 5083 5086 6061 6061 7075

2) Temper: soft, 1/4 hard, 1/2 hard, hard, H12, H14

3) Thickness: 0.2mm to 300mm

4) Width: 100mm to 2300mm, Length: up to 2300mm,

5) Main application: Tray, Road traffic signs, Car license, Automotive body, Wall decoration,

Auto radiator, Food container, Aluminum ceiling, Battery shell, LED Lighting, Kitchen rinse bath,

lamp shade , heat exchanger, nameplate, Power transformer, pallet etc.

CHEMICAL COMPOSITION

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

1060 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.6 | ||

1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.5 | ||

1100 | 0.95 | 0.05-0.2 | 0.05 | 0.1 | 99.0 | |||||

1200 | 1.0 | 0.05 | 0.05 | 0.1 | 0.05 | 99.0 | ||||

3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | 0.1 | remainder | ||||

Product Information

Aluminum sheet is usually according to the following two points:

1. According to the alloy composition is divided into:

High purity aluminum plate rolling (by the content above 99.9 high purity aluminum)

Pure aluminum plate (ingredients made from pure aluminum rolling)

Alloy aluminum plate (composed of aluminum alloy and auxiliary, usually with aluminum and copper, aluminum and manganese, aluminum and silicon, aluminum magnesium, etc)

Composite aluminum plate or brazing plate (through a variety of means of material compound special use aluminum material)

Outside package aluminum (aluminum coated aluminum sheet used for special purposes)

2. According to the thickness is divided into: (mm)

Sheet (aluminum sheet) 0.15 to 2.0

Conventional plate (aluminum sheet) 2.0 to 6.0

Medium plate (aluminum plate), 6.0 to 25.0

Plate (aluminum plate) 25-200

Super thick plate more than 200

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

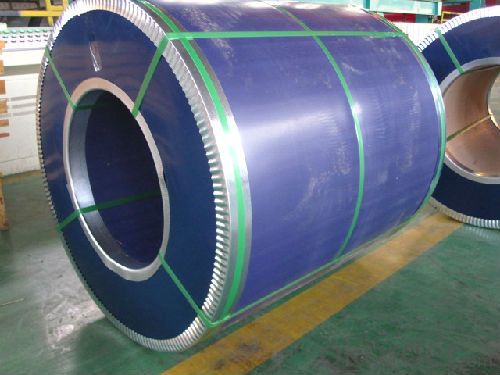

Images:

- Q:What are the different types of steel fasteners and their applications?

- There are various types of steel fasteners, including bolts, screws, nuts, and washers. Bolts are used to join two or more components together, while screws are typically used to fasten two materials by being inserted into one and creating a threaded connection. Nuts are used in conjunction with bolts to secure them in place and provide added strength. Washers are used to distribute the load and prevent damage to the materials being fastened. These steel fasteners find applications in various industries such as construction, automotive, aerospace, and manufacturing, among others.

- Q:How are steel products used in the construction of high-rise buildings?

- Steel products are commonly used in the construction of high-rise buildings due to their strength, durability, and versatility. They are used for structural components such as beams, columns, and frames, providing the necessary support and stability to withstand the weight and forces exerted on the building. Additionally, steel is often used for cladding, roofing, and façades, offering aesthetic appeal and protection against weather elements. Its flexibility allows for easy customization and modifications, making it an ideal material for constructing tall buildings efficiently and safely.

- Q:What are the different types of steel coatings for fire resistance?

- There are several types of steel coatings that are used for fire resistance, including intumescent coatings, cementitious coatings, and ablative coatings. Intumescent coatings are designed to expand when exposed to heat, forming an insulating char layer that protects the steel from high temperatures. Cementitious coatings are made of cement, aggregates, and additives, providing a dense and fire-resistant layer on the steel. Ablative coatings are designed to release a gas or vapor when exposed to heat, creating a protective barrier against fire. These coatings vary in their application methods, thickness, and performance characteristics, providing different levels of fire resistance for steel structures.

- Q:What are the uses of steel mesh in construction?

- Steel mesh is commonly used in construction for various purposes. It is primarily used as reinforcement in concrete structures to increase their strength and durability. Steel mesh is also used as a formwork support during the pouring of concrete, ensuring that it maintains its desired shape. Additionally, it is utilized in masonry and plastering works to provide structural stability and prevent cracking. In some cases, steel mesh is also employed as a safety measure, such as in fencing or as a barrier to prevent falls from heights. Overall, steel mesh is an essential component in construction, offering versatility and enhancing the structural integrity of various building elements.

- Q:What are the different types of steel fasteners?

- There are several types of steel fasteners, including screws, bolts, nuts, washers, and rivets. These fasteners are commonly used in construction, automotive, and manufacturing industries for joining or securing various materials together.

- Q:How is steel used in the production of solar panels?

- Steel is used in the production of solar panels as a structural component. It is used to provide stability and support to the panels, ensuring they can withstand various weather conditions and last for a long time. Additionally, steel is also used in the mounting systems and frames of solar panels, allowing them to be securely attached to rooftops or other structures.

- Q:How do steel products contribute to the agricultural and farming sector?

- Steel products play a crucial role in the agricultural and farming sector by providing durable and efficient equipment. From tractors and harvesters to storage silos and fencing, steel products offer strength and longevity, allowing farmers to increase productivity and yield. Additionally, steel structures such as barns and sheds provide essential shelter for livestock and equipment, ensuring their safety and well-being. Overall, steel products contribute to the modernization and efficiency of the agricultural industry, enabling farmers to meet the growing demands of food production.

- Q:How do steel products contribute to the defense and security sector?

- Steel products contribute to the defense and security sector in various ways. Firstly, steel is a crucial material in the construction of military vehicles, such as tanks, armored personnel carriers, and naval ships, providing them with the necessary strength and durability to withstand hostile environments and protect soldiers. Additionally, steel is used in manufacturing weapons and ammunition, ensuring their reliability and effectiveness on the battlefield. Furthermore, steel is utilized in the construction of military infrastructure, including barracks, bases, and fortifications, enhancing the overall security and defense capabilities of a nation. Therefore, steel products play a vital role in supporting and strengthening the defense and security sector.

- Q:How is steel wire used in the production of cables?

- Steel wire is commonly used in the production of cables as a core strength component. It provides the necessary strength and durability to withstand tension and bending forces, ensuring the cable can support heavy loads and resist breakage. Additionally, steel wire can enhance the overall flexibility and stability of the cable, allowing it to be easily installed and remain in place even under challenging conditions.

- Q:How is steel used in the production of machinery and equipment?

- Steel is widely used in the production of machinery and equipment due to its strength, durability, and versatility. It is used to manufacture various components such as frames, casings, gears, and bearings, providing the necessary structural integrity and mechanical capabilities. Steel's ability to withstand high temperatures, corrosion, and heavy loads makes it ideal for applications in heavy machinery, construction equipment, automotive industry, and many other sectors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coated Aluminium Sheet Coated Aluminium Sheet AA6061 5054

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords