Coated Aluminium Coil Sheet for Composite Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Description of Coated Aluminium Coil Sheet for Composite Panel

Alloy: 1050, 1100, 3003, 3005, 3105, etc

Thickness: 0.15mm~1mm

Painting Thickness: 5-10mic for back coating, 15-40mic for top coating

Paint Types: PVDF, PE, HDPE, LDPE, etc

Width: 900mm- 1950mm

Color: According to RAL colors or customer's samples

2. Application of Coated Aluminium Coil Sheet for Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Coated Aluminium Coil Sheet for Composite Panel

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

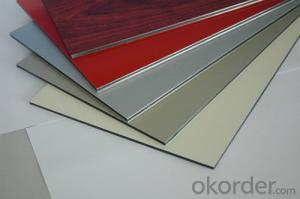

5. Image of Coated Aluminium Coil Sheet for Composite Panel

6. Package and shipping of Coated Aluminium Coil Sheet for Composite Panel

eye to Sky

eye to wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

- Q:Are the aluminum sheets suitable for HVAC (heating, ventilation, and air conditioning) applications?

- Yes, aluminum sheets are suitable for HVAC applications. Aluminum is a lightweight and corrosion-resistant material that is commonly used in HVAC systems due to its excellent thermal conductivity and durability. It is often used for ductwork, heat exchangers, and evaporator coils in HVAC systems.

- Q:Can 101 aluminum sheets be anodized in different colors?

- Indeed, it is possible to anodize 101 aluminum sheets in various hues. Anodization entails generating an oxide coating on the aluminum's surface, which can then be dyed to attain a plethora of colors. The quantity of sheets, in this instance 101, does not impede the capacity to anodize them in distinct shades. Every sheet can be anodized and dyed separately to produce a distinct and preferred color. Anodization is a versatile procedure that facilitates customization and color diversity, enabling the achievement of diverse tones and tints on each individual aluminum sheet.

- Q:8mm which type of aluminum plate is suitable for bending?

- How do I calculate the pressure of the seamless steel tube with the outer diameter of 300mm and the thickness of 18mm L=600mm? material

- Q:Aluminium magnesium alloy plate, 5052 aluminium plate, 5005 aluminium plate. 5252 aluminum plate performance and use

- Material details1 and 5052 aluminum magnesium alloy aluminum plate: 5052 aluminum plate belongs to the aluminum magnesium alloy aluminum plate, the use scope is widespread, especially in the construction industry cannot leave the alloy aluminum plate, also is the most promising aluminum alloy plate. The main alloy element of 5052 aluminum plate is magnesium, which has good corrosion resistance, good weldability, cold workability and medium strength.5052 aluminum plate is commonly used in the manufacture of aircraft and car fuel tanks, oil pipes, as well as traffic vehicles, ships sheet metal parts, instruments, street lamps, brackets and rivets, hardware, electrical appliances, such as shell.2 and 5005 aluminum magnesium alloy aluminum plate: 5005 aluminum plate, band strength and 3003, welding resistance, good processing, 5005 aluminum plate and 3003 alloy similar, with moderate strength and good corrosion resistance. The anodic oxide film is more bright than the oxide film on the 3003 alloy and is in harmony with the tone of the 6063 alloy.5005 aluminum plate is often used as conductor, cooker, instrument panel, shell and building decoration, building materials, internal and external materials, vehicle materials and so on.3 and 5754 aluminum magnesium alloy aluminum sheet: 5754 aluminum alloy has the characteristics of moderate strength, good corrosion resistance, weldability and easy processing and forming. It is a typical alloy in Al Mg alloy. In foreign countries, 5754 Aluminum Alloy plates of different heat treatment condition is the automobile manufacturing industry (car door, mould, seals), main materials used for canning industry.5754 aluminum is widely used in welding structure, storage tank, pressure vessel, ship structure and marine facilities, transport tanks as well as for the requirements of good processability, excellent corrosion resistance, high fatigue strength, high solderability and moderate intensity static situations.

- Q:Calculate the molar mass of the aluminum oxide. A 5.00g strip of aluminum is reacted in air, producing an oxide weighing 9.36g. Calculate the percent oxygen and aluminum in the compound.Calculate the % error for percent of aluminum calculated.

- 1) Yes, indeed. Al?O? is the correct formula for aluminum oxide. Because the ionic formula is Al?? and O??. (Aluminum has an oxidation number of 3+ ; and oxygen has an oxidation number of 2- . So a neutral ionic compound will have the formula Al?O?. Each element will take the number of the opposite ion.

- Q:Does it make any difference shiny side up, shiny side down when it comes to cooking with aluminum foil?

- The shiny side is slightly better reflector of heat. Face that side of the foil in the appropriate direction. To keep things cold, put the shiny side on the outside -- that will reflect incoming heat. To keep things warm, face the shiny side inward toward the hot food -- to reflect the heat that is trying to escape back into the food. Note that people often bake potatoes with the shiny side out -- that is because it makes for a better (prettier) presentation. In reality, baking them that way reflects the incoming heat on the outside, slightly slowing the cooking process. Of course, in reality, which side of the foil faces where makes little difference. It does make for lively conversation, though.

- Q:What is the typical weldability of aluminum sheets?

- Aluminum sheets are widely recognized for their exceptional weldability, thanks to their low melting point and excellent thermal conductivity. Various welding techniques, including TIG (tungsten inert gas), MIG (metal inert gas), and even spot welding, can easily be employed to join aluminum sheets. The weldability of these sheets can be further improved by utilizing specialized filler materials exclusively designed for aluminum welding. Nevertheless, it is crucial to acknowledge that the weldability may vary depending on factors such as the alloy composition, thickness, and surface condition of the aluminum sheet.

- Q:Aluminum standard 30*25*2500 to 1000 1 how to calculate the number of materials needed?. 2 how to calculate the cutting loss?

- The aluminum density of the alloy is about the same as this one, which can be roughly estimated.

- Q:How do aluminum sheets perform in terms of thermal insulation?

- Aluminum sheets are not effective in terms of thermal insulation. Due to their high thermal conductivity, aluminum sheets allow heat to easily transfer through them. This means that they are not able to effectively block or resist the transfer of heat, resulting in poor thermal insulation properties. If thermal insulation is the primary concern, other materials such as fiberglass, foam, or mineral wool would be more suitable choices.

- Q:Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coated Aluminium Coil Sheet for Composite Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords