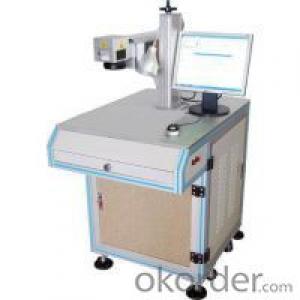

CO2 Laser Machine for Tyre Marking Machine CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

CO2 LASER FEATURES:

Our CO2 Laser Machine for Tyre Marking equipped the importing RF CO2 Laser, High-Speed Resonance Mirror System.

The speed is quicker and the performance is stable.This series Laser Equipments have widely won user’s trust depend on it’s superior performance and reliable quality.

MACHING POWER: 10W, 30W, 50W, 100W

TECHNICAL PARAMETERS:

| Matching Type | BMC10A | BMC30A | |

Technology

Parameter | Output Power | 10w | 30w |

| Wavelength | 10.64um | ||

| Repeat Frequency | ≤50khz | ||

| Marking Scope | 110mm x 110mm | ||

| Marking Speed | ≤7000mm/s | ||

| Min. Line Width | 0.015mm | ||

| Characters Type | English letters, numbers, production date and punctuations | ||

| Marking Depth | ≤3mm | ||

| Max. Production Line Speed | 30m/ min | 70m/ min | |

| Coding Lines | ≤8 lines | ||

| Input Power | 0.6kw | 1.5kw | |

| Electrical Source | 220V/ single-phrase circuit/ 50Hz (or 0 | ||

| 3A | 8A | ||

MAIN PARTS LIST:

| System Name | Parts Name | Amount | Standard Parameter | Manufacturer |

| Optical System | Main Control Box | 1 set | BPC-01A | Beijing Boaolaser |

| CO2 | 1 set | Continuous laser and average power 10w, 30w, 50w, 100w | USA Synard | |

| High Speed Laser Head | 1 set | ±10v<1.2ms | GS (USA) | |

| Beam Expander | 1 | 3X/ 4X | Beijing Boaolaser | |

| F-q Lens | 1 | F-110mm | RODENSTOCK (UK) | |

| Control System | Industrial Control System | 1 | 2.0 (socket478)/ 512/ 80G/ CD-ROM | Taiwan |

| Computer Monitor | 1 | 15'' | Founder | |

| Control Software | 1 set | Boao Laser Marking System Ver2.0 | Beijing Boaolaser | |

| Laser Control Card | 1 | BCC-A, RS232 | Beijing Boaolaser | |

| D/A Control Card | 1 | 16 bite D/A output, 4 input/ 4 output, I/O | Beijing Boaolaser | |

| Laser Code | 1 | Beijing Boaolaser | ||

| Worktable | Frame | 1 | Beijing Boaolaser |

- Q:Like only 90 or 120 degrees, but it's precisely controlled.Thanks!

- Agitator on a washing machine. Garage door opener. Vibrations on a vibrator. So on and so forth.

- Q:How to improve the mechanical properties of materials?

- As well as through the heat treatment to improve the mechanical properties of a certain aspect of the material.

- Q:where can i get the list sugar plant machinery with the details & market value?

- Ask Dole Pineapple or look on the US Dept Us Agriculture website or google

- Q:If the machinery that accomplishes X-chromosome dosage compensation in humans was defective (e.g., 1 protein was mutant), what do you expect the consequences would be? Choose one. a) no consequences b) XX embryos would not be viable c) XY embryos would not be viable d) both XX and XY embryos would not be viable

- B

- Q:Such as in terms of construction equipment like a crane, what is the maximum amount of weight that can be lifted by any existing machine?

- A crane's limitation is defined as metre-tonnes, because it is the moment that creates the limitation of the crane lift. A crane does the same amount of work to lift 50 tonnes at 10 metres as it does to lift 100 tonnes at 5 metres. That being said; I believe the largest single lift was perfromed by one of forty-two Lampson Tranis Lift IIs in Corpus Christi TX. The actual load was 1000 tonnes. And this just happens to be a MOBILE unit, on top of everything else!

- Q:why on ship machinery's are installed forward-aft & not port starboard?

- It is easier to pick up the frame spacings for structural support running fore/aft as opposed to port/starboard

- Q:Royal Co. acquired new machinery with a list price of $700,000. At the date of Purchase they received a $7,000 cash discount and paid $2,000 of delivery charges. Installation and worker training costs were $46,000 and $14,000 respectively. During installation, worker negligence caused $15,000 damage to other machinery in the factory building. What is the acquisition cost for the machinery?I am unsure what to include, deduct or add in the calculation. Any help would be great!

- Acquisition okorder

- Q:I hate working out in public gyms and exorcise rooms if other people are there for some reason. And I hate running in public (I've ran at night before, but now I don't have any time with so much schoolwork). I was wondering what some good exorcises i can do at home every day that don't take long but will make a difference. I was hoping to work my stomach muscles more so i can get in shape for swimsuit season. Thanks! (:

- brisk okorder

- Q:I remember a famous economist said that. Poor countries are economically advantaged to use manual labor instead of advanced technology so that they can employ everyone.

- If that's a famous economist, he's a stupid, famous economist. Pure poppycock. Productivity matters. That famous economist failed Econ 101. Is it leftist darling Paul Krugman? The guy who ignored the basic fact that all wealth destruction is bad and declared the 9/11 rebuilding in NYC a positive economic event?

- Q:I was wondering if a license from another country (say Ecuador) is valid here in the United States for operating heavy machinery? if not, what are the steps for a non-english speaking person to get this license if they know how to operate machines efficiently?

- Nope. Depending on where you live determining what u can do

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CO2 Laser Machine for Tyre Marking Machine CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products