Cnc Machining Turning Aluminium drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

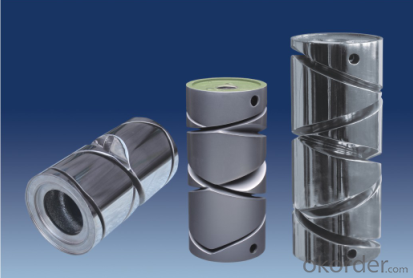

Cnc Machining Turning Aluminium drum of Winding Machine Parts

Adavantages:

Cnc Machining Turning Aluminium drum of Winding Machine Parts has the following advantages:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

Product Description:

Pictures shows of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

Models of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging & Delivery of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

· Q:What is the machine used for?

A:Cnc Machining Turning Aluminium drum of Winding Machine Parts is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q:What is a pedal loom?

- The pedal loom is a generic term for a textile machine with a pedal

- Q:When the textile industry, as well as the history of the textile industry development?

- Chinese machine textile originated in five thousand years ago Neolithic spinning wheel and waist machine. Western Zhou Dynasty with the traditional performance of the simple mechanical reeling car, spinning, looms have emerged, the Han Dynasty widely used jacquard machine, oblique loom, after the Tang Chinese textile machinery is maturing, greatly promoted the development of the textile industry.

- Q:The state of the textile industry machinery revitalization, expanding domestic demand, the specific policy is what?

- The domestic basic industry is weak, the basic parts can not keep up, affecting the quality of textile machinery products and mechanical and electrical integration level. Textile machinery product development and the lack of organic cooperation, affecting the use of textile products effect. Policy does not match, affecting the competitiveness of domestic textile machinery products. In view of these problems, China's textile industry has adopted a series of measures to vigorously develop the basic equipment of textile machinery, the introduction of foreign textile machinery technology, differentiated development strategy, and the introduction of the corresponding policy of supporting the development of textile machinery, and achieved good results The

- Q:What is a spinning wheel?

- Hand spinning wheel drive the power of the spinning wheel from the hand, the operation, need to shake the spinning wheel, hand in the spinning work

- Q:What is the task of preparing the process before spinning?

- The task of opening the cotton machinery to open the cotton is the first process of spinning, by different types of open-cleaning machine composed of the joint machine to complete the following tasks

- Q:Who invented Jenny spinning machine?

- In the mid-18th century, British goods were increasingly sold overseas, and the production of handmade workshops was inadequate. In order to increase production, people find ways to improve production technology. In the cotton textile sector, people first invented a shuttle called the weaving tool, greatly accelerated the speed of the weaving, but also to stimulate the demand for cotton yarn. In the 1860s, the weaver Hagreaves invented the "jenny machine" hand spinning machine. "Jenny machine" can be spinning a lot of cotton thread, greatly improving the productivity.

- Q:What are the risks of safety accidents in the textile machinery industry?

- There are all risks of security, one, the machine is faulty, do not attach importance to continue to use

- Q:Is there a textile industry in the Qin Dynasty?

- From the Han Dynasty, China's silk has been transported to foreign countries, becoming a world-renowned products. At that time from China to the West to the road, was Europeans known as the "Silk Road", China is also known as the "silk country".

- Q:What is the chenille mechanical principle?

- Its production and processing products called chenille yarn or spiral, broken wire, is a new variety of fancy

- Q:Textile machinery industry how to have prospects?

- As of the end of 2010, the industry total assets reached 77.613 billion yuan, an increase of 27.78%; industry sales revenue 815.65 billion yuan, an increase of 42.13%. Overall, after experiencing the decline in industry growth in 2008, the industry scale expansion rate significantly accelerated, the overall development trend is good

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cnc Machining Turning Aluminium drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords