cnc engraving machine for woods 300*400 cm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Syntec control system

2.9.0kw ai cooling spindle

3.Janpan Servo motor

4.Taiwan Hinwin rail

5.Vacuum table

Professional muti-function cnc engraving machine 1325

Main technical parameter

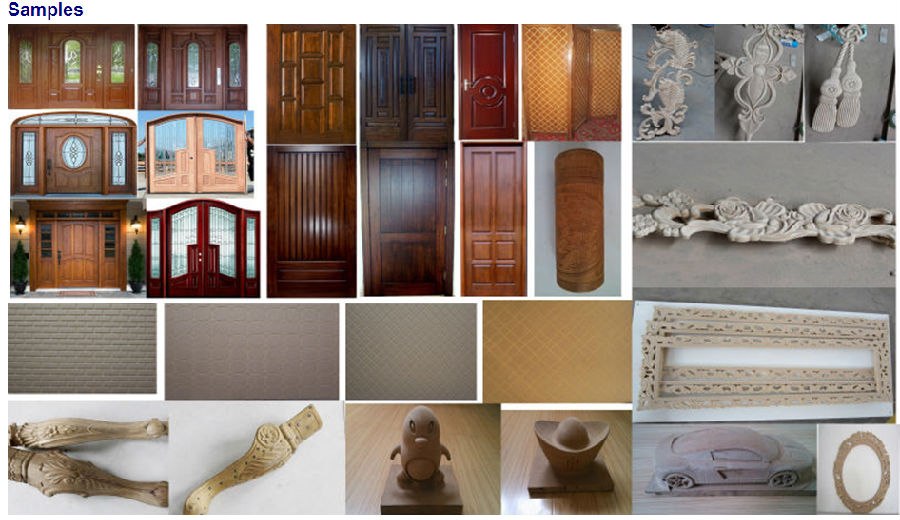

It can be used in carving on waved board, furniture door, arts door, paint free door, screen door and kinds of furniture.

Machine Size Work Envelope Repositioning Resolution Resolution Power Of Spindle Spindle Speed Max.Speed Max.Cutting Speed Bridge Clearance Control System Working Voltage Command Code | 2100×3500mm 1300×2500mm +0.02mm +0.001mm 9kw 0-18000(24000)rpm/Min 60000mm/Min 25000mm/Min 400mm SYNTEC control system AC380V/50Hz HPGL\G |

Machinery Characteristics:

Stable Structure: Square steel formed frame, stable and can not be deformed.

Perfect Parts: Imported Taiwan control system;AMT Line guide rail maid in Taiwan, due-row, four line ball slider, heavy loading and steady proceeding, German made ball lead screw with accurate cutting, Japan Servo Control system

Italy spindle motors.

l Good parts: The drive is more powerful: the use of well-known brands stepper motor,

become more powerful

l Armless automatic tool change system;magazine capacity 8(optional)

l High adhesion vacuum suction device;Displacement up to 230 cubic meters / hour

l Open software interface,.Excellent compatibility compatible of TYP3/ARTCAM/CASTMATE/WEITAI and other CAD/CAM design software Ensure that the design no problem.

- Q:What are the features of the spindle motor of the woodworking engraving machine?

- Fine machining spindle is characterized by low noise, high speed, high precision, suitable for processing particularly delicate workpieces, such as seals, nameplates, chest cards, gifts and so on. This kind of motor is usually a high speed variable frequency motor with less power and less than 250W. The disadvantage is that the ability to cut thick materials is poor and is not suitable for cutting thicker materials.

- Q:What specifications of linear guide rail are used in woodworking engraving machines?

- Engraving machine on the guide rail, according to its cross section on the width of the division, of course, the wider the greater the weight of support, the general use of 20mm and 25mm.

- Q:1325 woodworking engraving machine stepper motor power is how big?

- Stepper motor power consumption is very small

- Q:What are the commonly used transmission parts for woodworking engraving machines?

- Kyoho engraving machine experts believe that more classification methods of gear and gear transmission, with different classification standards, in accordance with the relative position of the gear tooth profile, gear shape, two axis gear and transmission gear between the external structure classification

- Q:Which brand is good for engraving machine? Which brand is good for woodworking engraving machine?

- Small advertising signs shop for the first time, the main production of three-dimensional characters, lights, crystal, double color, chest cards and other purposes, should buy ad grade. Generally speaking, the engraving machine is larger than 1200mm, and is not suitable for engraving fine shade and so on. It is suitable for sawing and making some large flat. In the 1200mm format and the following is a universal engraving machine, can be used as a double plate such as fine, and can be used to do menial work saw the word. For the machining of cylindrical or other special-shaped workpiece, as the need to install some jigs or rotating axis, which shows the high Z shaft column, the table to the head space is large, so you can use the special machine. If the seal shop is specially engraved seal, it can be equipped with a small laser engraving machine.

- Q:Woodworking engraving machine how to use the tool can not be hurt to the table?

- Then, according to the cutting depth set in the Thai region, the corresponding height is raised. Here, let the Z axis be zero again. This is the origin of the Z axis. According to the setting depth in the Thai Thai, engraving machine down to the lowest point is my family once a zero place, just on the top of the table, so that the material is fully engraved, and will not hurt the engraving machine table.

- Q:What is the problem of vibration of the Y shaft when the main shaft of the woodworking engraving machine rotates?

- Description of the spindle internal problems. The formation of electronic interference, it is recommended to replace the main shaft

- Q:A woodworking engraving machine can engrave anything

- Even if is the plane, is also divided into different processes, some engraving machine is a single spindle, some multi spindle, multi process carving products, only a single spindle carving process products to carving process products to keep the tool change, such as general advertising engraving, a spindle will be enough, but do the door, at least two knives, engraving machine spindle do not frequently change the knife, there is a spindle, N knife libraryknife, can automatically change the knife, time is short, fast. For example, Shenyang engraving machining center company also has such engraving machine and machining center.

- Q:How to operate the 6090 woodworking engraving machine Weihong control system

- In the open file loading and Weihong(2. to X.Y.Z cleared after the origin of coordinates)3. click the simulation [view in the motion control system is normal file carving]4. if third steps is normal, then rotate the spindle, spindle start, and then click on the manual by direction key 8*2 6*4 9*1 to control the engraving machine to find the origin on the boards.5. again cleared X.Y.Z [this is] the origin and the origin of the machine to ensure consistency in the document and the origin of Weihong wood

- Q:How can a woodworking engraving carve a right angle at 90 degrees?

- Look at the quality of the equipment you use. The quality of the equipment is very good. The quality is better than that of the equipment

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

cnc engraving machine for woods 300*400 cm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords