CNBM Wire Mesh with Customised Designed Mesh Size and Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 250000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.CNBM Wire Mesh with Customised Designed Mesh Size and Low Price Description:

PVC coated welded mesh with plastic covering is constructed with galvanized iron wire of high quality. It has PVC powder covering that is processed by an automatic machine. The smooth plastic coating on this corrosion protective wire is attached with a strong adhesive which make increases durability of the wire.

Hexagonal Wire Mesh is 1 1/2" x 17 gauge, zinc coated, galvanized woven wire Paperback Stucco Netting is made for building as reinforcement wire materials for cement, gypsum plaster, masonry veneer and ceramic tile. 1 1/2" (38mm) x 17 gauge, 1/4" self-furring woven wire in rolls, hexagonal mesh is formed with a twist of 17 gauge (1.38mm) galvanized steel wire. Paperback Stucco Netting is furred at 6" (152mm) vertically.

2.Main Features of CNBM Wire Mesh with Customised Designed Mesh Size and Low Price:

good corrosion resistance and oxidation resistance, serves well as strengthing, protection

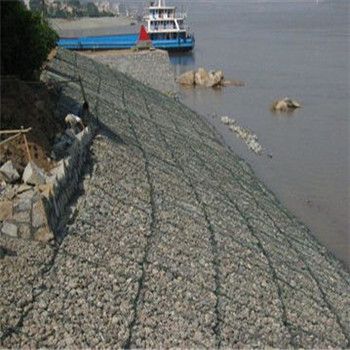

3.CNBM Wire Mesh with Customised Designed Mesh Size and Low Price Images

4. CNBM Wire Mesh with Customised Designed Mesh Size and Low Price Specification

Mesh | Wire Gauge(SWG) | Size(width×Length) |

1/2"

| 22,23,24,25 | 3'×100', 4'×100', 5'×100' |

3/4"

| 21,22,23,24 | 3'×100', 4'×100',5'×100'' |

5/8" | 22,23,24,25 | 3'×100',4'×100',5'×100' |

1" | 20,21,22,23 | 3'×100',4'×100',5'×100' |

(3CM) 1.09 | 19,20,21,22 | 3'×100',4'×100',5'×100'' |

(4CM) 0.847 | 18,19,20,21,22 | 3'×100',4'×100',5'×100'' |

2" (5CM) | 18,19,20,22,23 | 3'×100',4'×100',5'×100'' |

5.FAQ

①. What product specifications can be determined by customers?

A: Customers can choose the raw materials , the type of surface treatment and assembly, as well as packaing.

②.How long do orders take to produced and delivered?

Lead time varies case by case. The customers will be informed when an order is placed.

③.Do you offer samples?

Yes, we will offer samples for your reference to have a test .

- Q:Screen printing and screen printing plate on the photosensitive material What are the requirements

- Printing equipment is simple, the operation will be printed, the plate is simple and the low cost of adaptability strong Chinese printing applications wide range of prints: color oil painting,

- Q:Is the screen printing the best way? And other printing methods than it?

- Mass production, and is flat printing can be considered to contact gravure printing, but the plate cost is high

- Q:How to make screen printing layout smooth

- You use the water-based screen version, or oily screen version. Oily general mesh is more dense. Sensitive plastic easy to have static electricity. So the glue can not play too thick. The choice of sensitive adhesive is also important,

- Q:On the issue of their own screen printing

- Print a colored pattern on a white shirt, I'm now nothing I wanna know what i need ...

- Q:What is the process of the screen printing process?

- low image quality: screen printing speed is slow, not suitable for online production; ⑥ low image accuracy: screen printing resolution is not high, the conventional number of lines 24

- Q:How to clean the screen plate

- The screen is automatically cleaned, rinsed and dried, and the screen is automatically stopped when the set time is reached. The door is opened and the drying time is adjusted by pressing the start switch.

- Q:What is the principle of screen printing?

- When printing, the ink through the mesh of the mesh on the substrate to re-form graphics / text.

- Q:What are the reasons for the hair making of the screen plate?

- Exposure time is the most important, lack of time, after the version of the mucus to stay in the screen, affecting the printing edge, a long time, it is not easy to open the screen, it will be printed edge defects caused by burr.

- Q:What is the commonly used mapping software for screen printing?

- Screen printing commonly used mapping software can be used CorelDRAW, is a special vector graphics production software.

- Q:Screen printing ink firmness problem

- Screen printing rarely use water-based ink, because the water-based ink in the non-absorbent substrate adhesion fastness is usually much worse than the solvent-based ink, plus silk ink layer thick, adhesion is more problematic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CNBM Wire Mesh with Customised Designed Mesh Size and Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 250000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords