CNBM Tons of Potassium Sulfate (SOP) Project made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tons of Potassium Sulfate Project

General

CNBM is a high-tech enterprises international chemical engineering company, who is pioneering in chemical engineering technologies, and playing a leading role in new technology development, with capability of project consulting, design,procurement, construction management and production guidance. CNBM provide services of chemical engineering and technology, with offering a scope of supply ranging from process design till the supply of completely integrated plants. CNBM master a technology of Potassium Sulfate production line, Calcium Chloride production line,sulfuric acid production line other fertilizers.We have cooperated with many international companies on projects,located Indonesia,Philippines,India,Jordan,Egypt.etc.

Plant Configuration

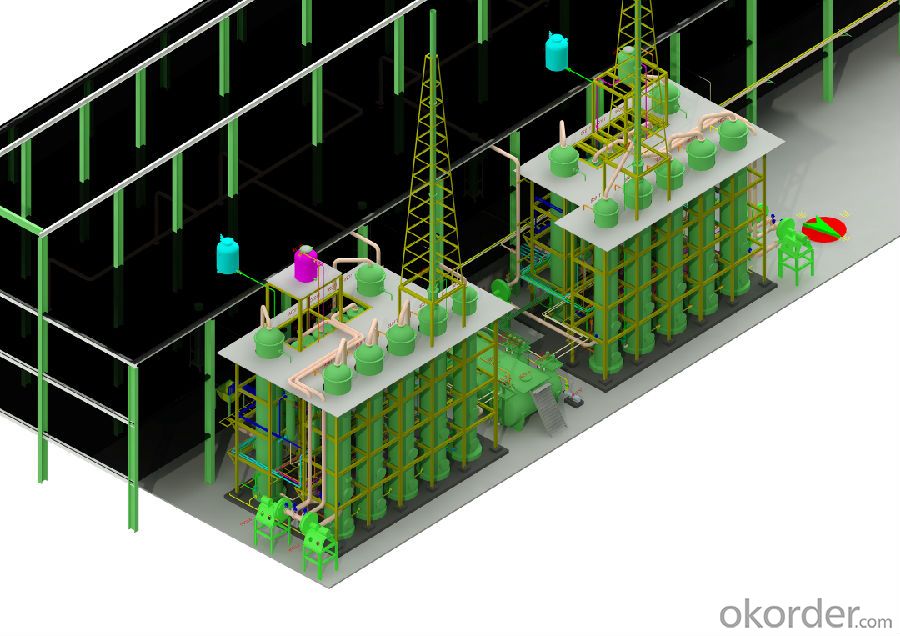

This plant is composed by the following units:

Unit 100: Raw material system

KCL from raw material warehouse is fed in Silo, and then go to screw conveyor, bucket elevator, en-masse conveyor, finally go to hopper on furnace top.

Sulfuric acid (98%) is pumped by sulfuric acid pump, go to high gravity tank on furnace top through the pipeline.

Unit 200: Furnace system

KCL from potassium chloride hopper continuously go through potassium chloride weighting balance to measure and control the flow, and with concentrated sulfuric acid of 98% from high gravity concentrated sulfuric acid tank, measuring and controlling the flow since it flowing into electronic metering device. Flowrate of KCL and Sulphric acid are controlled by DCS, continuously added into the reaction chamber of Mannheim furnace (near center part) based on a fixed feeding ratio. High temperature conditions provided by heating of the burner, materials begin to have chemical reaction. Mixing and pushing materials by the agitator blade of rotary arm of reaction furnace, moving from inside to outside, to complete the chemical reaction process of potassium sulfate and HCL gas.

Keeping normal height of the furnace bed, putting into the raw materials continuously, potassium sulfate is continuously ejected from the discharge hole of reaction chamber. The final product potassium sulfate fall into the cooler ejector through sealing piping, it can be conveyed to belt conveyor by air-sealed conveyor after cooling, stirring and preliminary crushing, the qualified potassium sulfate put into the final product storage bin, supplying to packing machine.

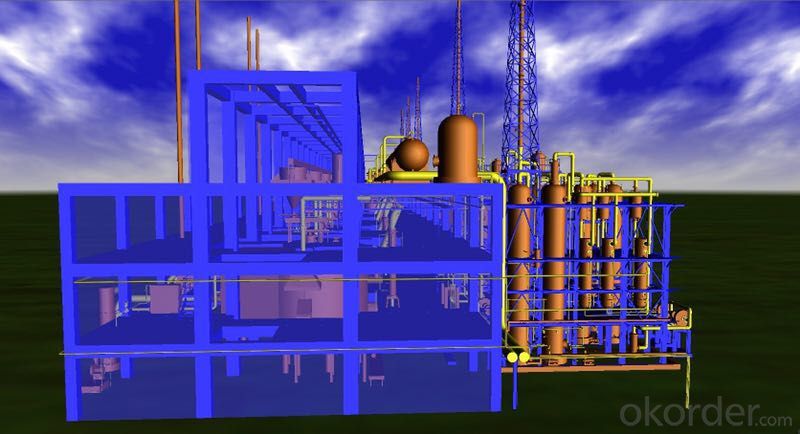

Unit 300:Hydrochloric Acid Absorption System:

Hydrogen chloride gas produced in the reaction is led out by the HCL door, through the cooling of graphite cooler, HCL gas goes through sulfuric acid gas washing tower, graphite absorption tower, FRP absorption tower. HCL fan suctioned pressurized HCL gas from the front tower to tail gas washing tower. Using water and dilute acid absorb HCL gas, making into approx 30-33% hydrochloric acid, then go to hydrochloric acid surge tank. The final product in Hydrochloric acid surge tank is pumped to Hydrochloric acid storage tank.

Finally, HCL tail gas can discharge to the atmosphere, in accordance with the national emission standards

Unit 400: Environmental Protection System:

In the actual production of SOP, sometimes we need to open the furnace door to examine and treat the abnormal problems of reaction chamber, making the necessary operation. Although every day it takes a very short time, there will spill a small amount of HCL when opening the furnace door, we particularly design gas-collecting hood installed above the HCL spillover place of furnace door, adopting glass steel environmental blower to suction exhaust HCL gas to the outside, pressuring into the environmental protection absorption tower. The recovery of HCL gas overflow will be made of dilute acid by using water to acid system making use of hydrochloride acid.

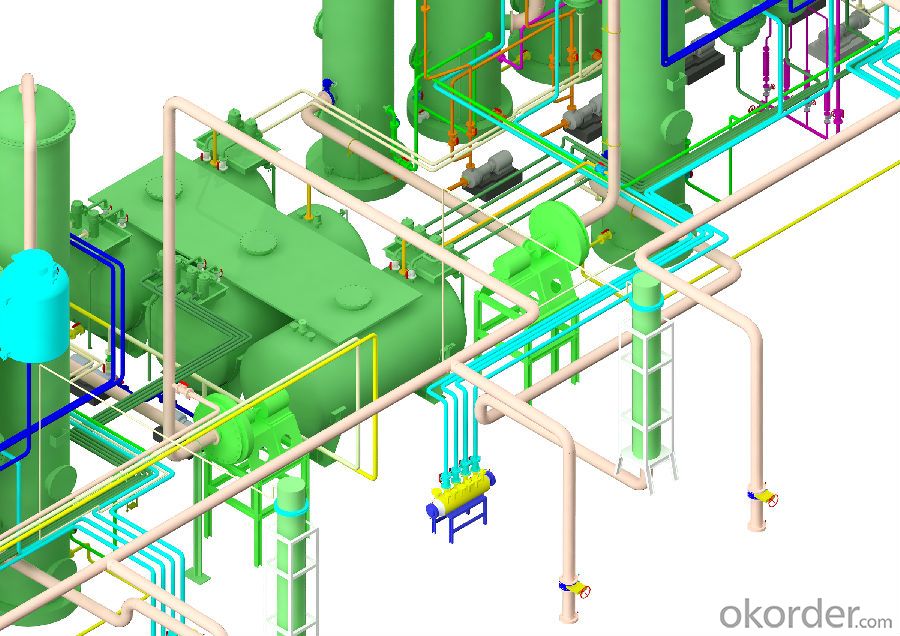

Unit 500: Circulating Water System (Utilities):

Hot water from the production system flows into the hot water pool, hot water is pumped to the reflection type cooling tower by hot water pump, hot water contact with cold air forming into cold water and falling into cold water pool. Cold water maintains a certain level, pumped to high gravity water tank through the pipeline.

Keeping the level of high gravity water tank, cold water flows into water distributor, it supplies to all production equipment respectively, cold water is heated to form hot water, then collect to hot water pool through the pipes. Thus completing cycle repeated.

Unit 600: Potassium Sulphate discharging from Furnaces and Bagging

The crude SOP product is delivered by belt conveyor, then to bucket elevator to vibrating screen,the unqualified potassium sulphate from the screen discharge to crusher. The crushed product is dropped down to the bucket elevator and then to vibrating screen.the qualified potassium sulphate from the screen is transferred to belt conveyor, product silo and make bagging.

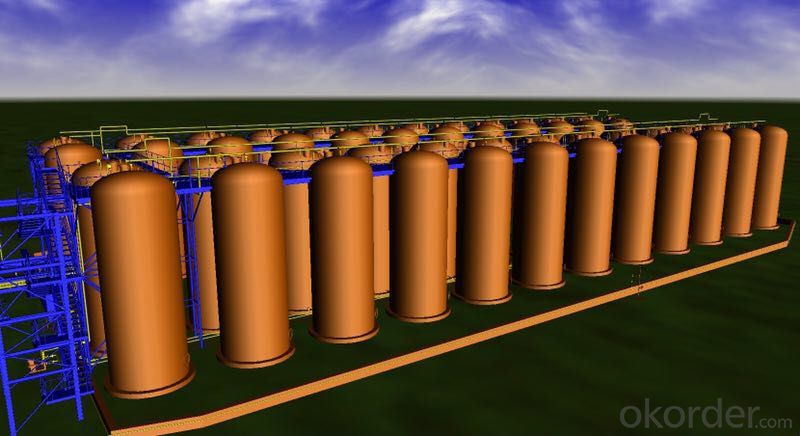

Unit 700: HCL Tank Farm

HCL comes from surge tank, then be fed to Storage tank in the tank farm. the storage tank be made of Fiber Reiforced Plastic material.

Outline

The unit design shall be based on the advanced technology and process automation as well as reliable technology.

Design capacity

Capacity : 100,000 MTPA(powder) for one production line

Plant availability : 330 days per year and 24 hrs per day

Design Battery Limits

| Item | Battery Limit |

| Raw Material | |

| MOP | At inlet of KCl tank |

| Sulphuric acid | Will be provided at the inlet of Sulfuric acid tank in battery limits with isolation valve |

| Product | |

| Potassium Sulphate | Outlet of SOP Product Silo |

| HCL | To HCL unload pipeline of HCL Tank Farm |

| Utilities | |

| Compressed air | Will be provided at one point within battery limits with isolation valve |

| Process water | Will be provided at one point within battery limits with isolation valve |

| Cooling Water | Will be provided at one point within battery limits with isolation valve |

| Natural gas | Will be provided at one point within battery limits with isolation valve |

| Power | Will be provided at one point within battery limits |

Site Climatic Condition

Temperature

| Max. recorded temp | 38℃ |

| Min. recorded temp | -23℃ |

| Annual average temp | 12℃ |

| Winterizing temp | -21℃ |

| Wet bulb temp | 20℃ |

| Dry bulb temp | 38℃ |

| Max.temp for mechanical civil structure design | 40℃ |

| Equipment exposed to sunlight | 70℃ |

| Soil temp for cable selection | 30℃ |

Humidity:

| Max relative humidity | 92% |

| Min relative humidity | 24% |

| Annual average relative humidity | 61% |

| Barometric pressure | 868.6mba(0.8686x10Pa) |

Wind

| Design wind velocity | 120Km/h(at 10m above grourd) |

| Wind load | 100Kg/m2(at 10m above ground) |

| Wind load coefficient | |

| Height above ground | coefficient |

| 10 | 1 |

| 20 | 1.2 |

| 30 | 1.3 |

| 40 | 1.4 |

| 50 | 1.5 |

| 60 | 1.6 |

| 70 | 1.7 |

Rainfall and snow precipitation

| Max in 24 hours | 80mm |

| Max in 1 hour | 40mm |

| Design snow load | 200kg/m² |

| Max snow precipitation | 80cm |

| Rainfall valve for sewer | 400mm/hr |

| Runoff coefficient | |

| Roof | 1.0 |

| Paved area | 0.85 |

| roadways | 0.4 |

| Unpaved area | 0.2 |

The Above information to be provided by the client.

Main Feedstock Material Requirement and Product Specification

Muriate of Potash (KCl):

| Parameter | Specification |

| K2O: | min.60% wt. |

| Moisture: | max. 0.5% |

| Partical size: | 90.0 % Min from 0.1 -1.0 mm |

Sulphuric Acid:

| Parameter | Specification |

| Type: | Commercial Grade |

| Concentration: | 98-98.5% |

| Specific gravity | 1840 kg/m³ |

| Others | No other significant impurity |

Product Specification

Potassium Sulphate (K2SO4)

| Parameter | Specification |

| Type: | Solid, Crystal |

| K2O: | Min.50% ±0.5% |

| Cl-: | ≤1.5%(adjustable) |

HCL

HCl-A(A-grade)

| Parameter | Specification |

| General Acidity | 31%±1% |

| Iron(as Fe) | ≤0.01% |

| Sulfuric Acid,as SO42- | ≤0.05% |

HCl-B(B-grade)

| Parameter | Specification |

| General Acidity | 31%±1% |

| Iron(as Fe) | ≤0.01% |

| Sulfuric Acid,as SO42- | ≤0.3% |

Consumption of raw material and utilities

Consumption of Raw Material:

| No. | Parameter | Units | Proposed Guarantee |

| 1 | Muriate of Potash(KCL) | MT / MT of K2SO4 | 0.850MT/MT |

| 2 | Sulphuric Acid(98%) | MT / MT of K2SO4 | 0.582MT/MT |

Consumption of Utilities:

| No | Parameter | Units | Proposed Guarantee |

| 1 | Natural Gas (NG) | MT / MT of K2SO4 produced | 75m3/MT |

| 2 | Diesel oil | MT / MT of K2SO4 produced | 65kg/MT |

| 3 | Electric Power | MT / MT of K2SO4 produced | 75kwh/MT |

| 4 | Process Water | MT / MT of K2SO4 produced | 1.25MT/MT |

| 5 | Circulating Cooling Water Requirement | MT / MT of K2SO4 produced | 60MT/MT |

| 6 | Supplementary Water | MT / MT of K2SO4 produced | 0.3MT/MT |

| 7 | Instrument Air | MT / MT of K2SO4 produced | 60m3/MT |

Environment

| No | Parameter | Units | Proposed Guarantee |

| 1 | Liquid Effluent | m3 / MT of K2SO4 produced | The liquid waste is very little and all of them is washing water which include a small amount acid. It will released to the treat tank and add some soda if needed. |

| 2 | Emission | Mg/Nm3 | (SO2):50 (HCl):25 |

| 3 | Solid Effluent | Kg / MT of K2SO4 produced | There are no solid waste produced from the whole production line |

| 4 | Noise | DBA | 80 at 1m from source 65 at Battery limit |

3D soft ware

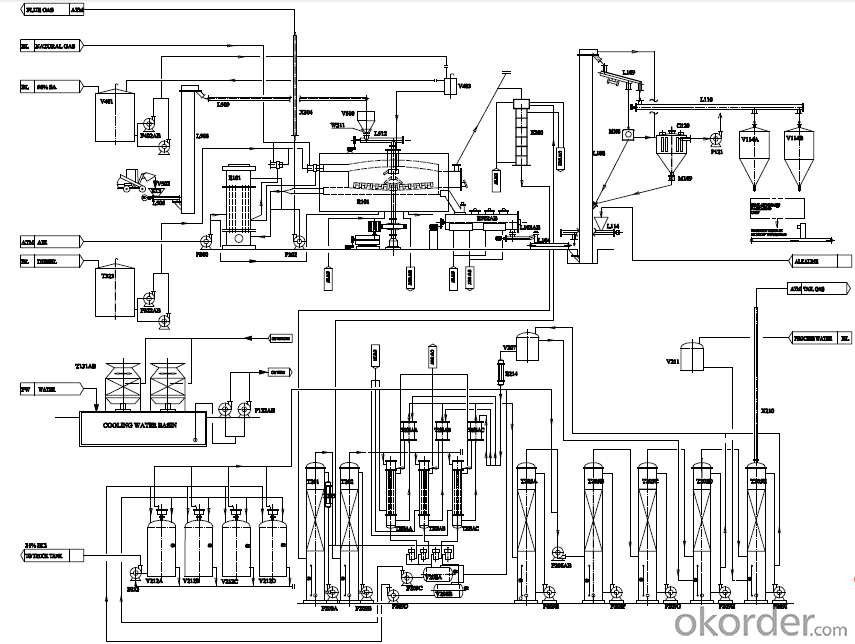

Process Flow diagram

- Q:For example: Humans vs. Artificial humans (robots)

- Heres a few I could think of. Salmon vs Hydroelectric dam Barnacles vs Boat Weathering and Erosion vs Road Rust vs Car

- Q:if you are not moving in outer space, is it possible to move without the aid of machinery?

- All you would need to do is throw some matter in one direction, and you would move in the opposite direction.

- Q:Machinery used in solid waste disposal can be subject to the regulation of the Noise Control Act. true or false

- It IS, not can be. subject to the same law as anything else.

- Q:Use of construction machinery

- Pump: a pump system is not installed in the car, pulling force is needed. Mobile concrete can be pumped from one place to another, simply as a separate pump. If the upward pumping is very difficult because of the weight of the concrete that you have no way to "take the 'steady conveying pipe.

- Q:Urgent! Is mechanical engineering major or special?

- The main research directions of mechanical engineering are: the design and development of mechanical equipment, the manufacture and management of mechanical equipment, the quality control of mechanical equipment, the performance test, the production equipment management, the use of nurturing and maintenance.

- Q:Does shear deformation or cutting speed tool temperature more?Thanks for help.

- Sheer deformation of the tool is negligible, therefore the deformation work converted into heat is very low. Excessive cutting speed will easily and quickly overheat the tool tip and may ruin its geometry and/or structure, depending on the tool material (hard metal or ceramic).

- Q:What mechanical keyboard is better for playing lol?

- In the early days of the keyboard, mechanical keyboards appeared, and had experienced a period of prosperity, such as the mechanical keyboard that was installed on earlier servers. Followed quickly by the high quality and inexpensive film keyboard replaced mechanical keyboard but did not disappear, as the representative of high-end products to today, the characteristic of mechanical keyboard itself is not flooded, so when the mechanical keyboard has experienced prosperity and decline

- Q:In terms of marine or vessel machineries, I did not understand it clearly, please explain, I need your help.

- Auxiliary would be like a pump or power generator, ancilliary would be more like drill press in the mechanics shop, one is needed to service the other, or another example would be the automatic potato peeler in the mess would be ancilliary

- Q:How much do you think it will cost if you buy 157 of agricultural machinery? And i know there are many types so just share all the info! ;) Thanks

- Given the over broad nature of the question, anywhere between US$157 and US$15,700,000 or more, It really depends on what you are buying; ratchets or combine harvesters.

- Q:Anybody knows what products can be manufactured with this?I need a list of products that can be manufactured with them ...so ....anyone?

- Virtually anything. The CNC technology is only limited by the material put into the machine and the program used to complete the machining process. I have even seen a type of CNC called CUPCAKE that can produce plastic prototyping for anything imaginable. Very cool!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CNBM Tons of Potassium Sulfate (SOP) Project made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords