CNBM hot sell 304,202 stainless steel pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

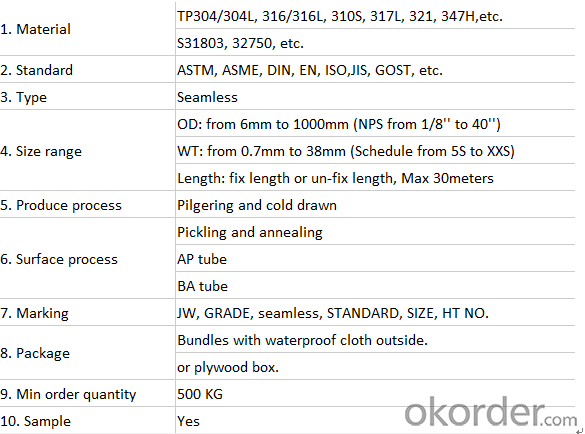

1,the desciption of the hot sell stainless steel pipe

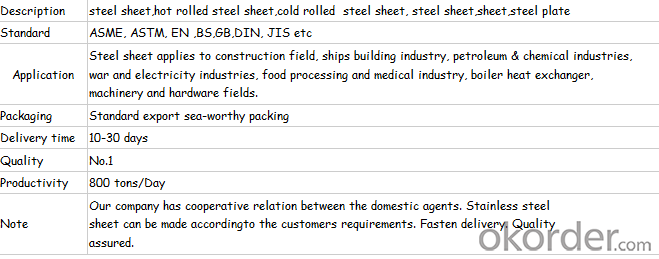

2,the application of the hot sell stainelss steel 304 201 stainless steel pipe

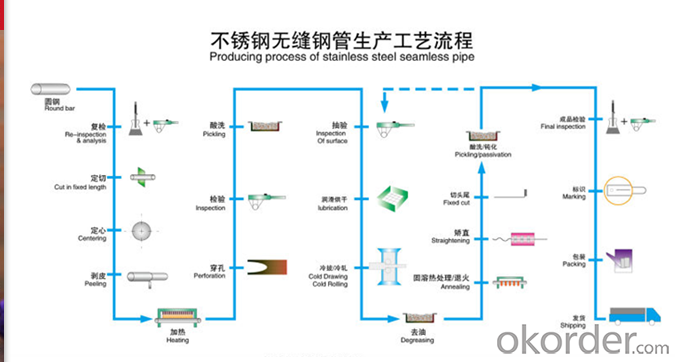

3,the producing procedure

4,related products show

5,FAQ

Q: WHAT ARE YOUR ADVANTAGES?

A: 1. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. 2. We have a strict quality control from production to delivery. 3. We take use of advanced system and tool to improve working efficiency and control every step. 4. Professional sales team to serve customers. 5. Samples can be provided as your requirements. 6. Professional packing team which keep every packing safely.

Q: WHAT ARE YOUR MAIN PRODUCT?

A: We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip / Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube / Stainless Steel Pipe Sheets.

Q: CAN I GET FREE SAMPLE?

A: YES. We can provide free sample. However, you should be responsible for the transportation freight. Please tell us your express account or please send us the transportation freight of samples firstly, then we can arrange sample delivery.

Q: HOW MUCH THE TRANSPORTATION FREIGHT WILL BE FOR THE SAMPLES?

A: The freight depends on the weight and packing size and your area.

- Q:Can stainless steel pipes be insulated with polyethylene-co-methacrylate?

- No, stainless steel pipes cannot be directly insulated with polyethylene-co-methacrylate. Polyethylene-co-methacrylate is a type of thermoplastic material commonly used for insulation purposes. However, it is not suitable for direct application on stainless steel pipes due to several reasons. Firstly, stainless steel is a high-temperature resistant material that can withstand heat and maintain its structural integrity over a wide range of temperatures. On the other hand, polyethylene-co-methacrylate may have a lower melting or softening point, which could result in the material deforming or deteriorating when exposed to high temperatures. Secondly, stainless steel pipes often require insulation materials that provide excellent corrosion resistance properties. While polyethylene-co-methacrylate can offer good chemical resistance against certain substances, it may not be as effective in protecting stainless steel pipes from corrosion caused by various chemicals or environmental factors. It is recommended to use insulation materials specifically designed for stainless steel pipes, such as mineral wool, fiberglass, or polyurethane foam. These materials are known for their excellent thermal insulation properties and compatibility with stainless steel, ensuring long-lasting and efficient insulation for the pipes.

- Q:Can stainless steel pipes be used for agricultural irrigation systems?

- Indeed, agricultural irrigation systems can utilize stainless steel pipes. With its exceptional durability and resistance to corrosion, stainless steel proves to be an appropriate material for a wide range of purposes, including agricultural irrigation. Its remarkable ability to withstand rust and corrosion, even when faced with moisture, chemicals, and fertilizers commonly employed in irrigation systems, is well-known. Furthermore, stainless steel pipes possess the capability to endure high-pressure water flow, enabling them to efficiently deliver water to crops. Notably, stainless steel is environmentally conscious, being entirely recyclable, which renders it a sustainable option for agricultural irrigation systems.

- Q:Can stainless steel pipes be used for water treatment facilities?

- Stainless steel pipes are suitable for water treatment facilities. The reason behind this preference is the excellent corrosion resistance properties of stainless steel. Since water treatment facilities handle various chemicals and substances that can cause corrosion in pipes, stainless steel is the ideal material choice. It provides a long-lasting and durable solution for transporting water and other fluids. Moreover, stainless steel pipes have a smooth surface finish, preventing the growth of biofilms and reducing the risk of contamination during water treatment processes. This is crucial for maintaining the quality and safety of the treated water. Another benefit of using stainless steel pipes in water treatment facilities is their ability to withstand high temperatures and pressures. They can handle the demanding operational conditions typically encountered in water treatment processes. Furthermore, stainless steel pipes are hygienic and easy to clean, making them perfect for use in water treatment facilities where cleanliness and sanitation are of utmost importance. In summary, stainless steel pipes are a reliable, corrosion-resistant, hygienic, and durable solution for water treatment facilities. They are well-suited for transporting water and other fluids in such settings.

- Q:What are the different types of stainless steel pipe elbows?

- There are several different types of stainless steel pipe elbows, including short radius elbows, long radius elbows, 90-degree elbows, 45-degree elbows, and reducing elbows.

- Q:Can stainless steel pipes be insulated with neoprene?

- Yes, stainless steel pipes can be insulated with neoprene. Neoprene is a versatile and durable material known for its excellent insulation properties. It is commonly used to insulate various types of pipes, including stainless steel pipes. Neoprene insulation can effectively reduce heat loss or gain, prevent condensation, and provide protection against extreme temperatures. It is also resistant to moisture, chemicals, and UV radiation, making it suitable for a wide range of applications. When properly installed, neoprene insulation can enhance the energy efficiency and performance of stainless steel pipes.

- Q:What is the difference between 304LN and 316LN stainless steel pipes?

- The main difference between 304LN and 316LN stainless steel pipes lies in their chemical composition and corrosion resistance properties. 304LN stainless steel pipes contain a higher percentage of chromium and nickel, making them more resistant to corrosion in general applications. On the other hand, 316LN stainless steel pipes have a higher content of molybdenum, which enhances their resistance to pitting and crevice corrosion, especially in chloride environments. Therefore, 316LN stainless steel pipes are often preferred in more corrosive and aggressive environments, such as marine or coastal applications, while 304LN stainless steel pipes are suitable for regular industrial and commercial use.

- Q:Can stainless steel pipes be used for wastewater treatment systems?

- Indeed, wastewater treatment systems can make use of stainless steel pipes. Stainless steel, being an exceptionally durable and corrosion-resistant substance, proves to be an excellent selection for pipes situated in challenging surroundings like wastewater treatment facilities. These pipes are capable of enduring the corrosive attributes of wastewater, encompassing chemicals and varying pH levels. Furthermore, stainless steel pipes possess a sleek surface, which aids in reducing the buildup of waste and bacteria, thereby guaranteeing the smooth movement of wastewater within the system. Moreover, stainless steel can be effortlessly cleaned and maintained, making it a cost-efficient and trustworthy alternative for wastewater treatment systems.

- Q:What is the difference between 321 and 316 stainless steel pipes?

- The chemical composition and intended applications distinguish 321 stainless steel pipes from 316 stainless steel pipes. 321 stainless steel pipes, containing titanium, ensure stability against chromium carbide formation, resulting in high resistance to intergranular corrosion even at elevated temperatures. Consequently, they find common use in industries like aerospace and power generation, where high temperatures are prevalent. Conversely, 316 stainless steel pipes lack titanium but incorporate molybdenum, which enhances their corrosion resistance, especially in environments with chloride ions, making them suitable for marine and coastal applications. Moreover, 316 stainless steel pipes excel in the food and beverage industry due to their exceptional resistance to acids and chemicals. To summarize, although both 321 and 316 stainless steel pipes exhibit excellent corrosion resistance, the presence of titanium in 321 stainless steel pipes elevates their resistance to intergranular corrosion at high temperatures, while the inclusion of molybdenum in 316 stainless steel pipes enhances their ability to withstand chloride-based corrosion in marine and coastal settings.

- Q:Can stainless steel pipes be used for nuclear waste storage?

- Stainless steel pipes can indeed be used for nuclear waste storage. Stainless steel is highly resistant to corrosion, making it an ideal material for containing and transporting hazardous materials such as nuclear waste. The properties of stainless steel, including its durability, strength, and ability to withstand extreme temperatures, make it suitable for long-term storage of radioactive waste. Additionally, stainless steel is non-reactive and does not leach out harmful substances, ensuring the integrity of the stored waste. It is important, however, to ensure that the stainless steel used meets the specific requirements and standards set for nuclear waste storage to ensure maximum safety and containment.

- Q:Can stainless steel pipes be used for pharmaceutical applications?

- Yes, stainless steel pipes can be used for pharmaceutical applications. Stainless steel is a preferred material in the pharmaceutical industry due to its high corrosion resistance, durability, and easy maintenance. It is used for transporting and storing various pharmaceutical products, as it ensures hygiene, does not react with drugs or chemicals, and can withstand high temperatures and pressure. Additionally, stainless steel pipes can be easily cleaned and sterilized, making them suitable for pharmaceutical applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CNBM hot sell 304,202 stainless steel pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords