CNBM Grade ASTM A615 Steel Deformed Bar Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

CNBM Grade ASTM A615 Steel Deformed Bar Price

Details of CNBM Grade ASTM A615 Steel Deformed Bar Price

Name | Deformed Bar |

Shape | Round Bar |

Standard | 1.GB1499.2-2007, HRB335, HRB400E 2. ASTM A615 Gr.40, Gr.60 3.BS4449/1997 |

Diameter | 6mm-50mm |

Length | 6m, 8m, 9m,12m as standard or as request |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of CNBM Grade ASTM A615 Steel Deformed Bar Price

Standard | Grade | Yield Strength Mpa | Tensile Strength | Elongation% |

BS4449:1997 | 250 | 250 | 295 | 22 |

460A | 460 | 485 | 12 | |

460B | 460 | 500 | 15 | |

GB1499.2-2007 | HRB335/335E | 335 | 455 | 17 |

HRB400/400E | 400 | 540 | 17 | |

HRB500/500E | 500 | 630 | 16 | |

ASTM A615 & A615M-04a | GRADE40 | 280 | 420 | 12 |

GRADE60 | 420 | 620 | 9 | |

GRADE75 | 520 | 690 | 7 | |

JIS G3112-2004 | SD295A | ≥ 295 | 440-600 | 17 |

SD295B | 295-390 | ≥ 440 | 17 | |

SD345 | 345-440 | ≥490 | 19 | |

SD390 | 390-510 | 560 | 17 | |

SD490 | 490-625 | ≥ 620 | 13 |

Size | WEIGHT | WEIGHT | QUANTITY | ||

LENGTH 6M | LENGTH 12M | LENGTH 6M | LENGTH 12M | ||

6 | 0.222 | 1.332 | 2.664 | 751 | 375 |

8 | 0.395 | 2.37 | 4.74 | 422 | 211 |

10 | 0.617 | 3.702 | 7.404 | 270 | 135 |

12 | 0.888 | 5.328 | 10.656 | 188 | 94 |

14 | 1.21 | 7.26 | 14.52 | 138 | 69 |

16 | 1.58 | 9.48 | 18.96 | 106 | 53 |

18 | 2 | 12 | 24 | 83 | 42 |

20 | 2.47 | 14.82 | 29.64 | 67 | 34 |

22 | 2.98 | 17.88 | 35.76 | 56 | 28 |

25 | 3.85 | 23.1 | 46.2 | 43 | 22 |

28 | 4.83 | 28.98 | 57.96 | 35 | 17 |

32 | 6.31 | 37.86 | 75.72 | 26 | 13 |

36 | 7.99 | 47.94 | 95.88 | 21 | 10 |

40 | 9.87 | 59.22 | 118.44 | 17 | 8 |

50 | 15.42 | 92.52 | 185.04 | 11 | 5 |

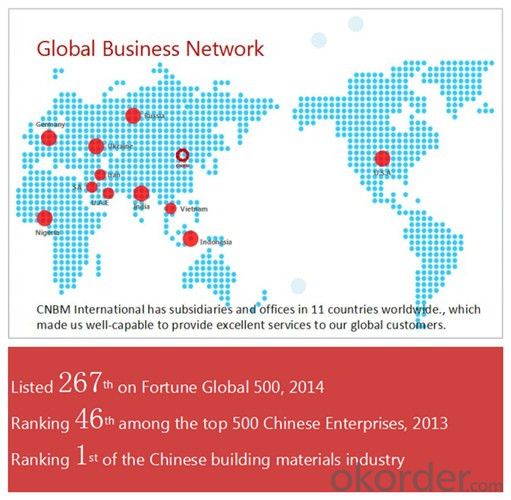

CNBM Introduction of CNBM Grade ASTM A615 Steel Deformed Bar Price

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of CNBM Grade ASTM A615 Steel Deformed Bar Price

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:What is the role of research and development in advancing special steel technology?

- The role of research and development in advancing special steel technology is crucial. Through continuous research and development efforts, new and improved manufacturing processes, alloys, and applications for special steel can be discovered and developed. This leads to advancements in the properties and performance of special steel, making it more durable, resistant to wear and corrosion, and capable of meeting the evolving needs of industries such as automotive, aerospace, and energy. Additionally, research and development help in optimizing production techniques, reducing costs, and promoting sustainability in the special steel industry. Overall, research and development play a vital role in pushing the boundaries of special steel technology, enabling innovation and driving progress in various sectors.

- Q:How does special steel behave under different types of loading conditions?

- Special steel behaves differently under different types of loading conditions. When subjected to tension, it stretches and elongates, but still maintains its strength. Under compression, it can withstand high pressures without deformation. Special steel also exhibits excellent resistance to bending, allowing it to maintain its shape under bending loads. Furthermore, it has high fatigue strength, making it suitable for applications involving cyclic or repetitive loading. Overall, special steel demonstrates superior mechanical properties and performance under various loading conditions.

- Q:What are the different methods of surface ion nitriding for special steel?

- Surface ion nitriding of special steel can be achieved through various methods. These methods encompass: 1. Utilizing DC Plasma Nitriding: Employing direct current (DC) plasma to ionize nitrogen gas, a plasma atmosphere is created. By subjecting the special steel to the plasma chamber and applying high voltage, the ions are accelerated towards the steel's surface, resulting in nitriding. 2. Adopting RF Plasma Nitriding: Similar to DC plasma nitriding, RF (Radio Frequency) plasma nitriding employs a radio frequency power supply to generate plasma instead of direct current. This method allows for better control over the nitriding process and can accommodate more intricate geometries. 3. Employing Pulse Plasma Nitriding: By applying short pulses of high voltage to the steel surface, a plasma discharge is created. These pulses are repeated at regular intervals, enabling precise control over the nitriding process. Pulse plasma nitriding is commonly used for steels with sensitive properties that may be affected by prolonged exposure to high temperatures. 4. Combining Plasma Assisted Nitriding: This method combines plasma nitriding with other surface treatment techniques, such as physical vapor deposition (PVD) or chemical vapor deposition (CVD). Initially, the steel is coated with a thin layer of reactive material, followed by nitriding in a plasma atmosphere. This combination enhances the surface properties of the special steel, such as wear resistance or corrosion resistance. 5. Employing Glow Discharge Nitriding: This method involves placing the special steel in a chamber filled with a nitrogen-rich gas, such as ammonia. Applying high voltage creates a glow discharge, which ionizes the gas and generates nitrogen ions that diffuse into the steel's surface. Glow discharge nitriding is commonly employed for small parts or components with complex shapes. It is crucial to consider factors such as desired properties, steel geometry, and application-specific requirements when selecting the most suitable method for surface ion nitriding of special steel.

- Q:How does special steel withstand high temperatures?

- Special steel is able to withstand high temperatures due to its unique composition and manufacturing process. Firstly, special steel is made from alloys that contain elements such as chromium, nickel, and molybdenum, which provide increased resistance to heat. These elements form a protective oxide layer on the surface of the steel, preventing oxidation and corrosion at high temperatures. Furthermore, special steel goes through specific heat treatment processes, such as quenching and tempering, which enhance its strength and toughness. These processes involve heating the steel to high temperatures and then rapidly cooling it, followed by reheating and slow cooling. This controlled cooling and heating process modifies the steel's microstructure, making it more resistant to thermal stress and deformation. Additionally, special steel is often designed to have a high melting point, which allows it to maintain its structural integrity even in extreme temperatures. The specific combination of elements and their ratios in the alloy contribute to the steel's ability to resist softening or melting when exposed to high heat. Moreover, special steel may also incorporate specialized coatings or treatments that further enhance its thermal resistance. These coatings can provide an extra layer of protection against heat, oxidation, and corrosion, making the steel even more durable and long-lasting in high-temperature environments. In summary, special steel withstands high temperatures by virtue of its unique alloy composition, heat treatment processes, high melting point, and additional protective coatings. These factors work together to enhance the steel's ability to resist thermal stress, deformation, oxidation, and corrosion, making it a reliable and durable material for applications in extreme heat conditions.

- Q:What are the different heat treatment processes for special steel?

- Some of the different heat treatment processes for special steel include annealing, quenching and tempering, hardening, case hardening, and precipitation hardening.

- Q:Can special steel be used in the wood manufacturing industry?

- Yes, special steel can be used in the wood manufacturing industry. Special steel, such as high-speed steel or tool steel, is often used in the production of cutting tools like saw blades or drill bits, which are essential in wood processing. These types of steel offer superior hardness, durability, and resistance to wear, allowing for efficient and precise cutting of wood. Additionally, special steel can also be used in the production of machinery or equipment used in wood manufacturing processes, providing strength and reliability.

- Q:How is special steel used in the aerospace manufacturing process?

- Special steel is used in the aerospace manufacturing process due to its exceptional strength, durability, and resistance to extreme temperatures. It is utilized in various components such as turbine engines, landing gear, and structural parts, ensuring the safety and reliability of aircraft. Additionally, special steel alloys are employed in critical areas where weight reduction is necessary, enhancing fuel efficiency and overall performance.

- Q:How does special steel contribute to the manufacturing of aerospace components?

- Special steel plays a crucial role in the manufacturing of aerospace components by offering superior strength, durability, and heat resistance properties. This type of steel, specifically designed for aerospace applications, ensures the structural integrity and reliability of crucial aircraft parts, such as landing gears, turbine blades, and engine components. Additionally, special steel's unique composition allows for reduced weight, thus enhancing fuel efficiency and improving overall aircraft performance. By providing these essential characteristics, special steel contributes significantly to the safety, efficiency, and advancement of aerospace manufacturing.

- Q:How does special steel contribute to the energy storage sector?

- Special steel plays a crucial role in the energy storage sector by providing essential components for various energy storage systems. One significant application of special steel is in the manufacturing of batteries, which are essential for storing energy in various forms. Special steel is ideal for battery casings and frames due to its high strength, excellent corrosion resistance, and durability. Battery casings made from special steel can withstand high pressures and protect the internal components from external impacts, ensuring the safety and reliability of the entire energy storage system. Furthermore, special steel is utilized in the production of electrodes, a critical component of batteries. Electrodes require materials that can efficiently conduct electricity while enduring repeated charge and discharge cycles. Special steel, such as stainless steel, possesses excellent electrical conductivity and can withstand the demanding conditions within batteries, making it an ideal choice for electrode manufacturing. Additionally, special steel is employed in the construction of infrastructure for energy storage systems. Steel structures are used to support large-scale energy storage devices like pumped hydro storage facilities and compressed air energy storage systems. These structures must be strong, durable, and resistant to environmental conditions. Special steel provides the necessary strength and corrosion resistance to ensure the longevity and reliability of these energy storage infrastructure projects. In summary, special steel contributes significantly to the energy storage sector by providing essential components for batteries, such as casings and electrodes. It also plays a vital role in the construction of infrastructure for energy storage systems. With its exceptional properties, special steel enhances the safety, efficiency, and durability of energy storage technologies, thereby facilitating the growth and advancement of the renewable energy sector as a whole.

- Q:What are the different medical grades of special steel?

- There are various medical grades of special steel used in the healthcare industry, including 316L, 316LVM, 304L, and 17-4PH. Each grade has specific properties that make it suitable for different medical applications, such as surgical instruments, implants, and medical devices. These grades are carefully manufactured to meet strict standards of corrosion resistance, biocompatibility, and mechanical strength required in medical settings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CNBM Grade ASTM A615 Steel Deformed Bar Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords