CNBM Glass Cutting Machine Production Line for Bulk Glass Cutting

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 100 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic Glass Cutting Line

1. Company Information

We has been a high and new technology enterprise specializing in developing, empoldering and selling a series of automatic glass machines, laser engraving machine, CNC router machine, window machines and door machines for many years.

Main products: Automatic Laminated glass (various shapes and low-E) production lines, automatic insulating glass production line, glass washing and drying machines, Automatic glass cutting machines, glass engraving machines, laser engraving machine, CNC router machine, CNC Woodworking machine, CNC Advertising machine, PVC window machine, PVC door machine, PVC window and door machine, PVC bending machines, PVC and Aluminum welding machine, PVC and Aluminum cutting saw, corner cleaning machine and other related products.

Advanced products, exquisite techniques, solid working and cordial services all give birth to the unique culture today. We always keeps step on the latest technology and is committed to providing the most advanced products for our customers. Moreover, we always emphasizes the training and quality of our staff.

During recent years, our company has taken "customer the highest, technique the first, service following" as our notion, "to be the most customer-oriented and service aware" as our task and "let customer fully know and select the product they need, provide customer the best solutions they need" as our responsibility. Constantly, our company provides high quality services and products for customers. That's why our company receives unanimous trust and good comments from our clients.

We hope to set up resplendence with wise people by superior qualitative products and high efficient services.

2. Technical parameter:

1).Equipment performance

Cutting Holder: Using Japan SMC Proportion solenoid valves, According to the glass thickness automatic adjustment pressure, The cutting holder Rotate 360°.

2).Positioning System

Mechanical photoelectric joint positioning

3). Conveying Device

AIR and Belt conveyor

3. Features of our Machine Line

CNC Auto Glass Cutting Machine Production Line adopt the most advanced Italy software.

Use imported high precision rack, slider and servo-motor, can be operated longer and faster.

CNC process control system, photoelectric positioning, convenient and accurate, airbag cutting, smooth precision.

Applicable to construction curtain walls, auto windshield, crafts, furniture, hollow, solar glass, etc, or set cutting for linear or special-shaped glass.

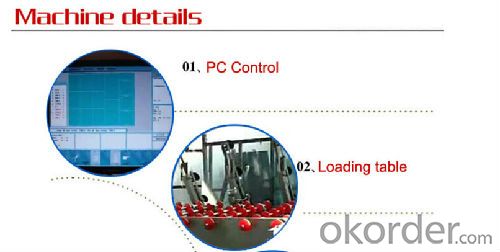

4. Main Introduction: Automatic glass loading machine

Product quality protection

If the product quality does not meet the standards set in your contract, Alibaba.com will refund the covered amount of your payment. On-time shipment protection

If your products are not shipped on time as per your contract, Alibaba.com will refund the covered amount of your payment. Payment protection

If the supplier breaks the on-time shipment or product quality terms of your contract, Alibaba.com will refund the covered amount of your payment. Product Details Company Profile Transactions History.

Report Suspicious Activity Company Information Packaging & Shipping Our Services FAQ Quick Details Condition: New Machine Type: Insulating Glass Production Line Production Capacity: 1200piece/day

Place of Origin: Shandong, China (Mainland)Brand Name: PARKER Model Number: IGV22

Voltage: 220-380v 50hzPower(W): 23.7kwDimension(L*W*H): 21000x2100x3300mm

Weight: 4800kgsCertification: CE Warranty: 1 years

After-sales Service Provided: Engineers available to service machinery overseas Insulating glass type: flat ,LOW-E, Coated Glass Insulating glass: double/ 3 piece glazing press insulating glass

washing speed: 8-12m/min Max working speed: 50m/min Process insulating glass size: First min:250x480mm firstMax:2200x3000mm ,2th Max:2.2x4.8m,

processing thickness insulating glass: 12-60mmWashing 1 piece glass thickness: 3-12mmangle of inclination: 6°

Insulating glass production line: CNC Glass Cutting Machine Glass Edge polishing Machine: China Insulating Process line

5. Our Service for our customers

Payment Terms

♦ L/C, 30% deposit by T/T,70% spare payment L/C.

♦ T/T, 30% deposit by T/T,70% spare payment before shipment.

♦ Western Union

Warranty Terms

All equipments is 12 months guarantee,lifetime maintance.

After Sale Service

Generally speaking,our Insulating Glass Processing Equipments need to install by our professional technician, Aluminum&UPVC Windows and Doors Processing Equipments does not need.

If buyers need to install by our technicians, the installation clause as follows:

6. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q:Can solar panels be installed on mobile homes?

- Yes, solar panels can be installed on mobile homes. In fact, mobile homes can be great candidates for solar panel installations due to their smaller size and affordability. Additionally, solar panels can help mobile homeowners save on electricity bills and reduce their carbon footprint.

- Q:In terms of efficiency and cost, what is the best solar panel. I am limited in the number of panels I can put up (probably 6-8) so they must be efficient, but cost is important also.What about these panels that can collect a wider range of light frequency?

- your initial outlay for a solar panel is very large in terms of output.......somewhere around $4 a watt......ie you want a panel that will run a 00 watt lightbulb? $400.00 please. enough panels to collect enough energy to recharge a battery bank to run the house overnight? well, I've been doing a lot of research for my condo project in St Thomas and it comes out to 0-20,000 US $ for a bedroom apartment. Now, after about ten years you have made your investemnt back.... and there are a lot of government rebate programs that lower the cost.. what I have found is solar is nice, but depending on how far north you live you may only have 4 usable hours of light a day. you may very well be better with a wind generator.wind blows all the time after all...Bergy and SouthWest Windpower make two good small home units...start there

- Q:Green issues aside, are solar panels worth it, monetarily speaking?I don't mean that my house might be worth more or any of that. All I am asking is this: if I invest in a set of solar panels, will the cost be paid back to me over time? If so, how long will it takegt;Take into account the following:. Currently I pay the electric company around $00 per month2. I use around 400 kilowats of energy per monthI realize that exact numbers are hard to come by, but any opinions are welcome.

- With tax incentives, yea it's worth it. It will take years to recoup the costs. You need to live there for a while.

- Q:Can solar panels be used in countries with limited sunlight?

- Yes, solar panels can still be used in countries with limited sunlight. While solar panels are most effective in areas with abundant sunlight, they can still generate electricity in countries with limited sunlight. Although the energy output might be lower compared to sunnier regions, advancements in solar technology, such as increased efficiency and better storage solutions, allow solar panels to be a viable renewable energy option in countries with limited sunlight.

- Q:i have a calculator with a solar panel what could i power with it? like could i hook it up to a psp even though it will take forever to charge? and how would i do this?

- All stable suggestions, yet you like 2 AA cells to keep the skill from the image voltaic panel to coach at ineffective night. The calculator probable has 2 or 3 rechargeable button cells. I somewhat have chanced on that non rechargeable Energizer or Duracell alkaline AA cells artwork sensible in those exterior/exterior LED lighting fixtures furniture furniture, so as which you would be waiting to recharge between short heating classes with an incandescent or a LED a lot longer. it is going to take distinctive days to recharge a pair of rundown AA with one calculator panel, so as which you will desire to decide utilising 2 or extra beneficial panels (in sequence if the calculator in simple words has one button cellular). 2 photograph voltaic panels in sequence from exterior LED lighting fixtures furniture furniture, could desire to recharge your AA cells in some hours of staggering photograph voltaic. I somewhat have 2 exterior lighting fixtures furniture furniture I keep charged via putting them the incorrect way up (without the stake and, defuser globe) on appropriate of CFL bulbs, one in each and every of that's 0 watts = forty watt equivalent. Neil

- Q:How much electricity can a solar panel produce?

- The amount of electricity a solar panel can produce depends on various factors such as the size and efficiency of the panel, the amount of sunlight it receives, and the location. On average, a standard solar panel can produce anywhere between 250 to 400 watts of electricity per hour.

- Q:How do solar panels connect to the electrical grid?

- Solar panels connect to the electrical grid through an inverter, which converts the direct current (DC) generated by the panels into alternating current (AC) that is compatible with the grid. This AC power is then fed into the main electrical panel of the building and can be used to power appliances and devices. If the solar panels generate excess electricity, it can be sent back to the grid, and if there is a shortfall, electricity can be drawn from the grid to meet the demand.

- Q:I mean when light hits the solar panel where does the energy go and what does it become? Be specific.

- Visible light from the sun is in the form of photon before hitting the solar panel. In a silicon solar panel, the photon is caught by the semiconductor material. Energy equivalent of the photon is then used to excite an electron from the semiconductor molecule. The aggregate of free flowing electrons form the current in a closed electric circuit. The efficency of conversion from sun light to electricity is not 00%. The majority of light energy hitting the solar panel is dissipated in the form of heat. As technology advances, the conversion efficiency is improving, hence reducing the cost of solar energy.

- Q:Can solar panels be installed on sloped roofs?

- Yes, solar panels can be installed on sloped roofs. In fact, sloped roofs are one of the most common types of roofs where solar panels are installed. The angle of the roof can be adjusted to optimize the positioning of the solar panels and increase their efficiency.

- Q:Can solar panels be installed on factories or manufacturing facilities?

- Yes, solar panels can definitely be installed on factories or manufacturing facilities. In fact, these large industrial buildings often have expansive roof spaces that are ideal for installing solar panels. By harnessing solar energy, factories and manufacturing facilities can significantly reduce their reliance on traditional energy sources, lower their carbon footprint, and potentially save on electricity costs in the long run.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CNBM Glass Cutting Machine Production Line for Bulk Glass Cutting

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 100 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products