CMAX WINE/WATER FLEXITANK FOR TRANSPORTATION-A grade

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 7000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Secure Quality and Safety of Bulk Wine

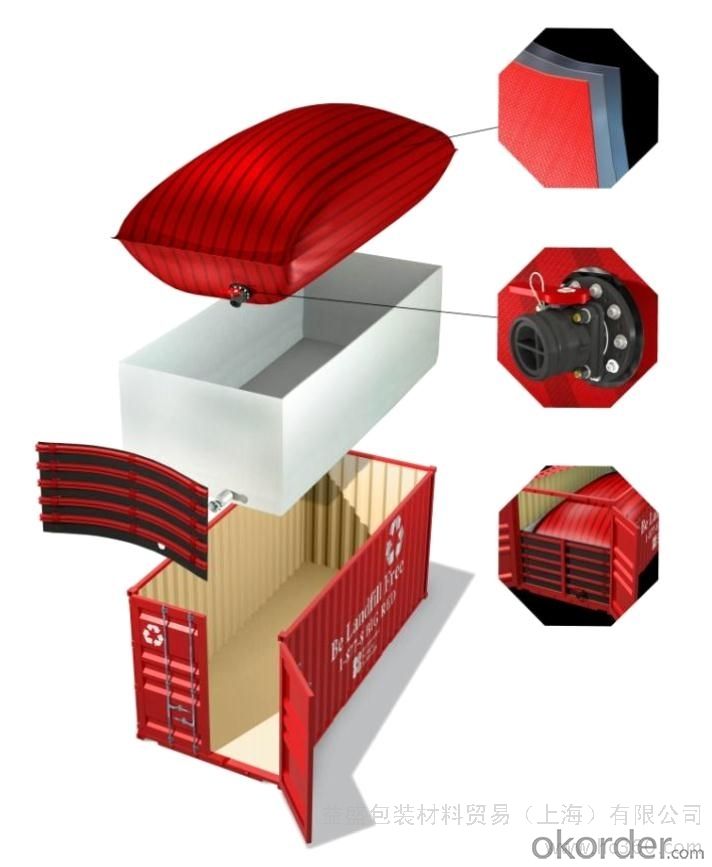

CMAX Wine Tank , is a system specially designed for bulk wine transportation.

uCompared to conventional flexitanks, this wine tank secures quality and safety of bulk wine inside:

Superior performance in oxygen resistance

with aluminium oxygen resistant barrier, its oxygen transmission rate ≤0.5 cm3/m2·24h·0.1Mpa.

uDecrease oxygen transmission by 50% compared to conventional flexitank with EVOH barrier.

Material Tensile Strength MD(N/15mm) Tensile Strength TD(N/15mm) Oxygen Transmission (cm3/m2·24h·0.1Mpa)

Aluminium 30.4 28.2 ≤0.5

EVOH 22.3 21.1 ≤1

uBetter tensile strength than EVOH

The aluminium oxygen resistant barrier much more durable,

with tensile strength of 33.88MD(N/15mm), 30.72TD(N/15mm),

increase tensile strength by more than 30% compared to EVOH barrier.

uFDA, EC approved, food grade

All PE materials, tested by SGS, are in full compliance with the Food and Drug Administration( FDA) and regulations for polyethylene used in article that contact with food, and in full compliance with European Commission Directive 2002/72/EC and its amendments relating to plastic materials and articles intended to come into contact with foodstuffs.

uSpecial Designs for securing hygiene

- PE Bonnet, surrounding the valve, secure valve in clean and hygiene environment.

- Food grade stainless steel flange and valve

uStrong Rigid Frame Bulkhead

Strong steel frame bulkhead with PP backing panel strengthened the safety during transportation

.

- Q:The company shipped the goods in container liquid bags, and the liquid bag manufacturers suggest that we buy Marine Insurance to cover the losses caused by the accident during the transportation, and all risks?

- How much is the cost? You should ask the insurance company directly. The premium is based on your value.We can't figure it out.Only formula, generally speakingAll risks premium rate = 0.4%, war risk premium rate = 0.03%The rate for FPA and WPA is 0.1%Take a computer and count it yourself. It's not difficult, you know it once.

- Q:How many tons can a large container hold in one container?

- The loading capacity can be calculated according to the size of the container. The container of the same size is slightly different because of the difference of structure and manufacturing materials.

- Q:How is the container liquid bag unloading process carried out?

- The first is to make sure that the trailers are parked to the ground level. In order to ensure safety, the local handling of goods cannot be carried out at a steep angle. This is our first concern. Second then look at the left door of the container and conclude that when the security situation is outstanding, you can open the right door and open the right door only. The ability to find more appropriate content within the scope of effectiveness.

- Q:Is it possible to export container liquid bags (cooking oil) as dangerous goods?

- It's easy to leak a leak, as soon as a touch of Mars or flammable material catches fireSo plastic packing is recommended!

- Q:What kind of general chemicals can be packed in container bags?

- Food categoryWine, edible oil, concentrated juice, food additives, sorbitol, palm oil, soy sauce, Yellow Wine, mineral water, malt extract, syrup, etc.

- Q:Brief introduction of container liquid bag

- Container liquid bag is a new type of software package container that can store and transport all kinds of non dangerous liquid cargo. Each container can be placed in a container of 20 feet, with a capacity of 14-24 cubic meters and a maximum of 24000 litres of liquid storage and transportation. The tank, can replace the expensive in non hazardous liquid transportation on drums and other traditional packaging.

- Q:What brand of container liquid bag is good? How to lead the liquid bag?

- Function: the produced liquid bag converts the standard container of 20 feet to a transport container capable of carrying 24000 of the bulk liquid. The structure is simple and the installation is fast. Only 2~3 people can complete the loading preparation within 20 minutes;Value: inexpensive, and can be folded in the empty bag distribution to reduce transport charges, folding volume is only one cubic meter, after unloading without return.

- Q:How long will it take before the container is changed? The box? Which department manages the container terminal?

- Generally speaking, ordinary containers are not changed as long as they are not damaged.

- Q:How can the corn cob packed in ton bags fit into the container and ship by sea?

- Empty containers do not unload, open half of the door, cut packets, and then use the conveyor belt to corn grain to the box, but the door needs a stack of bags wall, to avoid the overflow of corn.

- Q:Are container liquid bags expensive to produce? What machines are needed?

- The outer layer is made of 1 layers of PP, made by peripheral suture. Auxiliary baffle, fixed floor, square steel. The cost is mainly PE PP filmThe main machines are heat sealing machine, valve press machine, sewing machine.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX WINE/WATER FLEXITANK FOR TRANSPORTATION-A grade

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 7000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords