CMAX Series Automatic Pipe No-dust Cutter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Our pipe extrusion line can be used to produce PVC, HDPE, and HDPP pipes with the diameter between 12mm and 400mm. The well-coordinated components, coupled with auxiliary machines, allow this pipe production line to produce pipes for different purposes, including drain pipes, water supply pipes, electrical conduits, PVC fire-retardant pipes, as well as piping for use in chemical industry.

Working flow:

Mixer→ Vacuum feeding →Material dry → Single screw extruder →Marking line extruder(co-extrusion)→Vacuum calibration spraying cooling tank → Spraying cooling tank→ Color-ribbon printer → Haul-off machine →Cutter →Stacker

Packaging & Delivery

| Packaging Detail: | plastic film package or according to customers' demand |

| Delivery Detail: | 30 days after receiving 30% advanced payment |

Specifications

1.Easy to operation and running steadily

2.Good after-service

3.Preferential price

4.Advanced Design

Main charaters:

This line can solve the problems of high temperature melting, high viscosity, easy-decomposition. The

special designed screw, gearbox, tooling, and HMI system make the line reliable and easy operation.

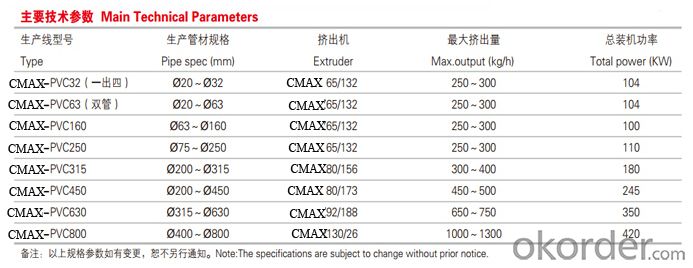

Main Technical Parameters

If you are interested in our product, please be free to contact us.Whether we could cooperate, we would do our best to help you. I’m confident that will be benefit to you and us!

FAQ:

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the diameter of pipe(inch or mm); thickness of pipe wall(mm); width and thickness of sheet (mm)? If profile product, you’d better offer the picture of sample or drawing of sample.

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

- Q:Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Cable extruder type 657090 machine, describes the diameter of the screw, the unit is mm.The greater the number, the greater the equipment, the greater the amount of gumIt is usually marked on the control cabinet of the equipment

- Q:extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Or the outer lubrication part of low molecular weight is replaced by macromolecule lubrication

- Q:What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- The temperature setting of the extruder is related to the material you manufacture. If the type of plastic is different, the setting temperature is different, and the material of different manufacturers is also slightly different from the temperature setting.

- Q:Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- How big is it? Not too big. I suggest using a 40 or 30 too big block. You have to use a special break knot.

- Q:Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat,

- Q:What is an extruder?

- Coextrusion is divided into two color co extrusion and hard and soft coextrusion.

- Q:Extrusion blow molding machine, storage or continuous type good?

- and material in the screw for a long time to use the storage type is also in order to meet the demand for raw materials productsIf you are doing small things, your hourly output will not consume the maximum hour.

- Q:producing polyethylene polypropylene fiber, masterbatch in the dark spot under the light, that is, masterbatch does not change, filter replacement frequently, half an hour... 40The equipment is Changzhou Riyue extruding machine, production of polyethylene polypropylene masterbatch, a dark spot in the light, it is not frequent replacement of masterbatch, filter plugging, half an hour, I added the 30% filling masterbatch, how to solve this problem? Other particles are not wet either. Masterbatch is not turned for help

- Is that settled? This technology is not available online! No one wants to say free, need technical contact me!

- Q:why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- Tensile strength is divided between longitudinal and transverse, and PE bags are transversely increased, available 8CLLDPE is added, longitudinal can be added to medium, medium density or high-density material to increase tensile strength.

- Q:Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Series Automatic Pipe No-dust Cutter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords