CMAX Large Diameter HDPE Water Supply and Gas Supply Plastic Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery:

| Packaging Detail: | Export packing, covered with film for dustproof, wooden crates packing for sea transport |

| Delivery Detail: | 50 days after receiving 30% advanced payment |

Water Supply And Gas Supply HDPE Large Diameter Pipe Production Line

Welcome to visit our Water Supply And Gas Supply HDPE Large Diameter Pipe Production Line!

Application:With this production line you can extrude high quality large diameter water supply and gas supply pipes.

The pipes produced by our line have excellent stiffness and flexibility, resistance to creep deformation,excellent heat-linkage. Large diameter HDPE pipes start to play very important role in the city water and gas supply systems.

Properties and Advantages: The production line consists of control system, extruder,mould, calibration unit, haul-off unit,planetary cutter and stacker.

Downstream equipment:This line is assembled lattice or spiral mould,new type calibration unit and spraying cooling bath. Advanced PLC control system and large chromatic liquid-crystal screen make the operation more convenient, having a friendly human-machine interface.

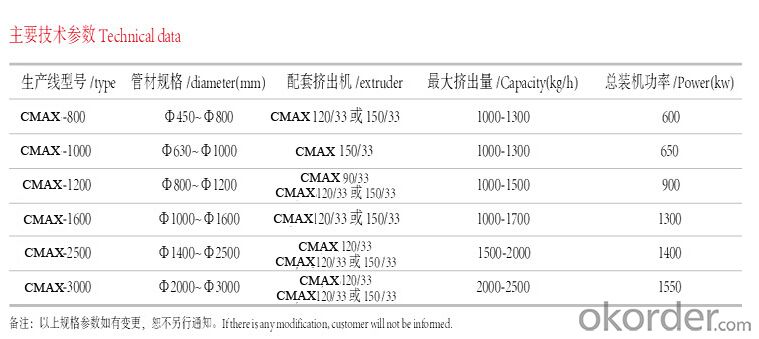

Main Technical Parameters:

Our company can design and manufacture products with different specs for clienteles.

The features:

1, We have set up one special forging team to design –develop-produce-distribute-debug-repair for our clienteles.

2, We possess strong technical power, high-tech, one complete set of checkout equipment, abundant debugging experience and timely after-sale service.

3, The most crucial is that we brave enough to innovate, keep enterprise, keep improving.

If you are interested in our product, please be free to contact us. Whether we could cooperate, we would do our best to help you. I’m confident that will be benefit to you and us!

1. The Extruder:

2.The Die Head:

3.The Vacuum Sizing Water Tank:

4.The Spraying Cooling Water Tank:

5.The Caterpillar Tractor:

6.The Cutter:

7.The Stacker:

8. The HDPE Pipe:

- Q:Before and after the original good tune, up and down again before and after the tune, before and after, and up and down again

- The nose is not accurate enough or wornOr the screws are not screwed in placeOr die inappropriate, too large

- Q:How to adjust the 65 screw gap in the extruder?

- That's the tune.This should be practical learning. The outlet plane of the barrel is about 3 mm in diameter.

- Q:What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- Setting the temperature completely depends on the actual situation.Generally, the position of the leaky hopper is lower than the temperature of the extruder barrel and the die head

- Q:Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q:What is the waste gas produced by the extruder, granulator and mixer?

- Do you want water spray, dry filter, carbon adsorption, fan, and discharge? Will that be better, thank you?Chasing the answerIf the exhaust gas contains acid and alkali waste gas (slightly acid base acceptable), there is no need to water spray, the main role of water spray is used to neutralize the acid and alkali containing exhaust gas. The exhaust gas is dry organic waste gas, only dry filter, activated carbon adsorption odor can be discharged.

- Q:Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- I am a professional pipe mold, can you say more details?

- Q:when I use armature voltage feedback (host start speed 50, normal can produce 10It is normal to start at 80 or 150 of the speed, but after a few minutes the motor does not turn. 590 alarm (missing pulse alarm). When I change the feedback mode to speed feedback, my host sometimes starts and sometimes fails to start. I hope you help me, how should I adjust?. Thank you。

- You can adjust the proportional gain, and if you don't move, the parameter has this problem, you should check to see if you really lost the pulse

- Q:The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

- Q:Produce 10 square wires with the smallest extruder

- If it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q:PLC based extrusion machine control system design graduation thesis and PLC based injection molding machine control system thesis content?

- Tip two: choose topics based on your interests. The title selection and refining skills of the two, is from the author's hobbies and interests, only conform to the topics and interests, the author accumulated data can work normally, language applications can also Practice makes perfect.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Large Diameter HDPE Water Supply and Gas Supply Plastic Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords