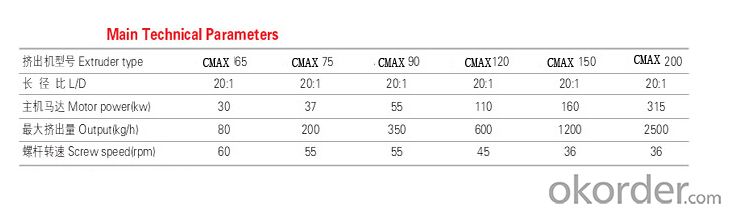

CMAX High Output Rubber Plastic Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Wooden crate |

| Delivery Detail: | 15 days when we received your PO |

Automatic Plastic Filament Wire Making Extruding Binding Machine

1. Easy to operate

2. Producing plastic filaments of diameter 1.2mm-8.0mm

3. Fit various standard moulds,easy to change

4. Producing speed up to 40kgs per hour

Features

1. Adjustment of extruding and winding speed for adjustment of wire diameter;

2. Sound roundness of extruded wire and stable wire diameter to promote forming production rate and ensure quality of plastic spiral;

3. Non-trained operators can grasp the skill in a short period.

4. For a variety of materials, like PET, PVC,

Technical Parameters

If you need a binding machine for your office or work space, you have come to the right place. MyBinding.com is your premier source for binding systems and supplies. In fact, we carry more binding machines and book binding systems than any other company on the Internet. No one knows more about these products than we do. We carry systems for traditional plastic comb, wire-o, and spiral coil binding as well as the Velobind and ProClick systems. If you're new to the market, try some of our excellent learning resources. The video to your right is a great place to start. In addition, we've featured helpful machine descriptions below. And, as always, please call, email, or chat if you have any questions!

- Q:Who knows the temperature regulation method of the extruder?Any information will do

- Extrusion molding in plastic processing is called extrusion, using hydraulic pressure in rubber extruder processing in extrusion die extrusion. That itself means that the material through the extruder barrel and screw the function between the side heating plasticization, screw edge is pushed forward, a processing method of continuous head made by various sections of finished or semi-finished products.In the fiber chemical industry is also useful in the extruder to the spinneret for melt spinning. The material, process of extrusion used in thermoplastic plastics and rubber, for batching, granulation, rubber filtration, continuous production, manufacturing various continuous products such as pipe, profile, sheet (or sheets), thin film wire and cable coating, rubber tire, tube noodles barrel, a sealing strip, the production efficiency is high. In the production of synthetic resin, can be used as reactor extruder, continuous polymerization and processing, in rubber industry, the compression ratio of different extruding machine can be used to unmasticated natural rubber of different materials. Compression extrusion machine than some different. [edit this paragraph] the principle of extrusion molding material since the bucket into the barrel, the screw rotates under the action of the cylinder wall and the surface of the screw friction shearing forward delivery to the feeding section in the loose. Forward transport also is compacted; the compression section, screw groove depth, further compaction, while the barrel heating and screw and cylinder wall friction shear, the material temperature rise began to melt, the compression section ends; homogeneous section material uniform, constant temperature, fixed quantity, squeeze out to melt. After a head forming, by setting the product.

- Q:Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- See section - cross section. Setting adjustment with RPC

- Q:What is the waste gas produced by the extruder, granulator and mixer?

- Plastic is a chemical product, and the waste gas produced by the process is organic waste gas. The commonly used and relatively efficient treatment method is activated carbon adsorption. The specific work process is as follows: exhaust gas, air pipe, dry filter, activated carbon adsorption, fan and discharge

- Q:Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- They can see it moving.God doesn't need itSometimes you hear, fifth hand material,Cool sounds in the swirling smokeCoagulation together, I have left their land,Yesterday was a similar experience, ha ha

- Q:Why do screw extruders often extrude light red plastic products?

- Cause this situation. Please clean the hopper thoroughly. The screw is also drawn out and cleaned up. It should be easy to solve.

- Q:The working principle of an extruder

- The material is moved forward by the extrusion of the screw and the barrel, and the material is fully homogeneous and plasticized in the process of material advance. Then the material is extruded by a certain shape of the die by the die of the die.

- Q:What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

- Q:Basic parameters of extruder screw

- 3, compression ratio epsilon, also known as the geometric compression ratio of screw, is the ratio of the volume of the first screw groove to the volume of the last screw groove at the homogenization section. It is determined by the physical compression ratio of plastics - that is, the density of the product and the density of the performance of the feed. The extruder is relatively compressed, the purpose is to make granular plastics fully plasticized and compacted. The selection of compression ratio should be different when different kinds of processing plastics are used. According to the compression ratio, the types of screw can be divided into three types: equidistant, unequal depth, equal depth, unequal distance, unequal depth, unequal distance. Among them, equidistant and unequal depth is the most common one. This kind of screw is easy to process, the contact area of plastic and cylinder is large, and the effect of heat transfer is good.

- Q:Why? What is the raw material of plastics? What is the process flow of the process?.

- 1. injection molding2., the structure is relatively complex, high appearance requirements. Extrusion does not meet requirements3. most are: ABS, ABS+PC, PP and so on4., according to color requirements granulation - drying particles - filling the mold ---- debugging injection molding machine ---- injection molding production - after the selection of finished packaging (if silk screen requirements, but also the need for silk screen)

- Q:There is a 90 extrusion machine, used in the production of communication cables (outside the cable core is extruded with a layer of LLDPE), now is the configuration of Y2-280M-490KW167A inverter type ACS510197A + ABB), General Motors now found low speed when the current is too large, what reason? How to solve? The details are as follows: used for communication cable production HYA30*2*0.4, 1, line speed is 50 m / min, inverter display frequency 35.3HZ current: 116A; 2, line speed is 40 m / min, inverter display frequency of 28.2hz, current: 140A3, line speed is 35 m / min, the frequency converter significantly method: 157A 24.6HZ frequency current, because the product variety and technical reasons, we need to be in the frequency of 10HZ production. Now, it seems that if I reduce the speed again, the current will probably exceed the rated current. What should I do? Is the motor changed to frequency conversion motor? Or inverter? How to solve? Please heroes pointing, thank you!

- Yes, the load characteristics and control characteristics are also to be matched. Otherwise, it will be very inappropriate and lead to abnormal phenomena.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX High Output Rubber Plastic Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products