CMAX Conical Twin-screw Plastic Extruder For High-speed Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

conical twin-screw extruder for high speed profiles is successfully developed by our company according to the market and clients’ demands, Mainly used to produce PVC door & window profiles etc, mainly for supporting high-speed extrusion line, a mode double out production line or windowsill board extrusion line and so on. Such kind of extruder is welcomed by the users with high output, extrusion stability, low- energy consumption.

Advantage:

High flexibility through gentle, homogeneous plasticization

AC motors for low energy consumption

A choice of different screw geometries for processing customer-specific PVC compounds

Low maintenance screw and an air-cooled barrel

Powerful gearbox; robust and compact design

Excellent price-performance ratio

Packaging & Shipping:

Packaging: PE film wrapped around & wooden pallet or wooden case worthy for long distance sea and land transportation ;

Delivery: 30 working days after receiving down-payment.

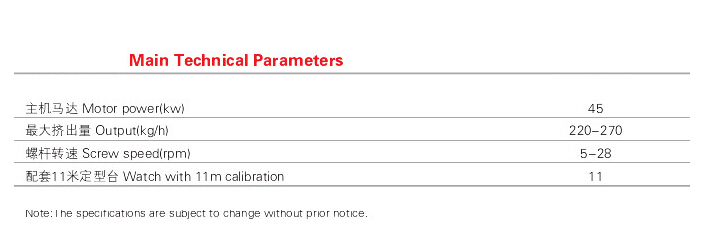

Technical Data:

Company Information

CNBM International Corporation

(CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.With the advantages in Cement, Composite Materials, New Building Materials and Engineering, We are enlarging sub-brand. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. In line with the business, CNBM International launched E-business platform Okorder.com. It conformed the best resource and logistics to meet the customers’ request with 24 hours full-time service.

Our Vision: Initiate new global trading structure; create new value for benefit related partners.

We will do utmost to promote rational use of resources under the new structure, meanwhile, create new value of “green, environment friendly and sustainable’ for a more prosperous future.

CNBM International Co. Carpet Dept.

At CNBM International Co. Carpet Dept., we design and weave beautiful carpets of superb durability - with axminster, tufted and wilton carpets to suit all hospitality environments. · There is no size limitation on rug size. Rugs can be created with a variety of materials from pure wool to woolen silk, from natural fiber to chemical fiber.

- Q:Before and after the original good tune, up and down again before and after the tune, before and after, and up and down again

- The nose is not accurate enough or wornOr the screws are not screwed in placeOr die inappropriate, too large

- Q:the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Is the fitting of the moving parts normal?.Is there an impact on the extrusion chamber?.

- Q:What raw material does the extruder use?

- The utility model has the function that the plastic melt from the extruder barrel is well distributed in the die runner so as to be extruded and formed from the die at a uniform speed. The forming action of an extrusion die is in the process of complete extrusion (see plastics processing). A plastic extruder consists of an extrusion system, a drive system and a heating and cooling system. The classification system of extrusion system includes 1. extrusion screw, barrel, hopper, head, and mould, plastic extrusion system by plasticizing evenly into the melt, the establishment of Liu Hesheng basic information name in this process and Liu Hesheng taught: - professional engineering

- Q:Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- See section - cross section. Setting adjustment with RPC

- Q:Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q:Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q:What should be paid attention to in the daily maintenance of the extruder?

- Attachment(1) inspect the rolling barrel, vibrating screen, motor and so on, and leak out the sealing parts.(2) cooling equipment and piping are clean and clean, and there is no suspended impurity in industrial soft water. Water filters and water tanks should be regularly checked, cleaned, kept clean and replaced with new water.

- Q:Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q:What are the components of an extruder?

- The driving system of an extruder is to drive the screw, providing the torque and speed required by the screw in the extrusion process, usually consisting of an electric motor, a reducer, and a bearing.3. heating and cooling device for extruderHeating and cooling are necessary conditions for the process of making a plastic extruder. It includes two aspects:(1) now host extruder is usually divided into electric heating, resistance heating and induction heating, heating installed in the fuselage, neck, head of each part. The heating device heats the plastic in the outer barrel to increase the temperature required for the process operation.(2) the cooling device is designed to ensure that the plastic is in the temperature range required by the process. Specifically, to eliminate the excess heat generated by the shear friction of the screw rotation, in order to avoid the temperature is too high, so that plastic decomposition, coke burning or stereotypes difficult. Cylinder cooling water cooling and air cooling is divided into two kinds, small and medium sized extrusion machine adopts air cooling is more appropriate, large use more water or two kinds of combined cooling; cooling water cooling screw mainly adopts the center, the purpose is to increase the solids conveying rate, stable glue volume, and improve product quality; but in the cooling hopper one is, in order to strengthen transport of solid material, prevent warming plastic sticky jam outlet, two is to ensure the normal work of the transmission part.

- Q:producing polyethylene polypropylene fiber, masterbatch in the dark spot under the light, that is, masterbatch does not change, filter replacement frequently, half an hour... 40The equipment is Changzhou Riyue extruding machine, production of polyethylene polypropylene masterbatch, a dark spot in the light, it is not frequent replacement of masterbatch, filter plugging, half an hour, I added the 30% filling masterbatch, how to solve this problem? Other particles are not wet either. Masterbatch is not turned for help

- 7042, no tax 9350-9400 yuan / ton, 02TN26 no tax,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Conical Twin-screw Plastic Extruder For High-speed Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords