CMAX Ceiling Suspension System Tee Gird CMAX Ceiling Suspension System Tee Gird

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

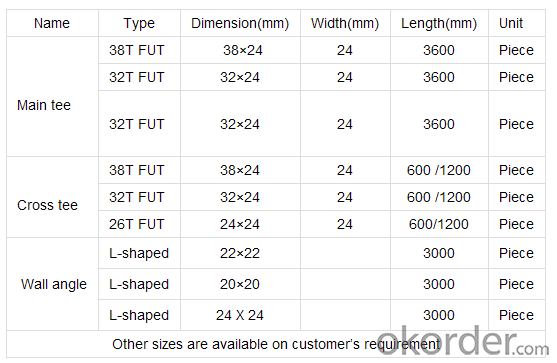

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q:Light steel keel gypsum board ceiling or aluminum-plastic plate ceiling good?

- Light steel keel gypsum board ceiling to brush paint, the surface is not good cleaning, with aluminum-plastic plate to do the ceiling color can be a long time to keep bright and easy to clean.

- Q:I see someone with a special tool to cut the keel, but do not know what is the name, it is difficult to find online, I would like to ask you know? Description: shape similar to the guillotine, put the keel, a force will be a light steel keel cut off.

- Automatic chase cut

- Q:What is a Ceiling Grid?

- your frame

- Q:Light steel keel partition keel spacing 300, the number of meters per square meter vertical keel?

- Light steel keel gypsum board partition, the main materials and accessories requirements 1. Light steel keel main pieces: along the top keel, along the keel, strengthen the keel, vertical keel, horizontal keel should meet the design requirements. 2. Light steel skeleton accessories: support card, Cato, angle care, connectors, fixtures, wall keel, pressure and other accessories should meet the design requirements. 3. Fastening materials: nail, expansion bolts, galvanized self-tapping screws, wood screws and adhesive joints should meet the design requirements. 4. Fill the sound insulation material: according to the design requirements. 5. Overlay plate: Gypsum board specifications, thickness by the designer or by drawing requirements selected.

- Q:Brother with light steel keel, gypsum board and nine pens made a walk into the cloakroom, would like to hang on the wall about 50 LCD TV, can not do ah? Afraid of not strong, Are there any instructions?

- The blacksmith is fixed to increase the contact surface.

- Q:Light steel keel 38 main dragon and 50 vice dragon of the national standard thickness is owe

- 38 The thickness of the main keel is 0.8 0.9 1.0 50 vice keel GB thickness is 0.5

- Q:It is done before the floor tiles, or in the shop after the tiles to do it?

- Look at the floor tiles empty how much! If not, then can! Ask the master in the punch when the point of attention! To prevent the broken brick!

- Q:Light steel keel ceiling how?

- Lasting corrosion resistance: galvanized more than 120g / ㎡, much higher than the GB / T11981-2008 requirements, has a high anti-corrosion anti-rust ability. High load high strength: made of high quality steel Q195, has a unique structural design, widening the wing, wings and other side design and side stiffeners, making the product high strength, good plasticity, a certain toughness, and in line with the United States ASTN580 shock requirements, with the role of absolute fire, durable. High construction efficiency: the use of advanced technology in Germany, the cold bending by the process of high-quality keel products, simple structure clear, without any accessories, installation are more simple and easy to operate.

- Q:Light steel keel wall hidden acceptance of what is the hidden content? (Not a ceiling)

- 1. The variety, specification, performance and moisture content of the keel, fittings, wall panels, filling materials and caulking materials used in the skeleton walls shall meet the design requirements. There are sound insulation, heat insulation, fire retardant, moisture and other special requirements of the project, the material should have the appropriate performance level of the test report. 2 skeleton wall works Border keel must be firmly connected with the base structure, and should be flat, vertical, position is correct. 3 skeleton in the keel spacing and structure of the connection method should meet the design requirements, the skeleton of the equipment pipeline installation, doors and windows openings and other parts to strengthen the keel should be installed firmly, the correct position, fill the material should be set to meet the design requirements. 4 wood keel and wood wall panel fire and corrosion treatment must meet the design requirements. 5 skeleton wall wall panels should be installed firmly, no delamination, warping, cracks and defects. 6 seam joints used in the joints of the wall method should meet the design requirements. 7 skeleton wall surface should be smooth, consistent color, clean, no cracks, seams should be uniform, straight. 8 skeleton on the wall of the holes, grooves, boxes should be the right position, sets of anastomosis, neat edges. 9 skeleton wall filled with the material should be dry, fill should be dense, uniform, no fall.

- Q:Rush! Light steel keel ceiling how to determine the ball line?

- Suspension point line and ceiling height line First to find the indoor level, pop 50 (read: five) horizontal line (500mm from the ground level) For example, if the ceiling is 2.8M high, then from the 50 line up 2.3m, (horizontal allowable deviation of ± 3㎜) [PS: 2.8M is the completion of the surface size, meaning the ceiling when the size of finished, measured from the ground is 2.8M Need to deduct the hanging stalk, hanging pieces, the main keel vice keel, ceiling material. Completed surface maintained at 2.8M

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Ceiling Suspension System Tee Gird CMAX Ceiling Suspension System Tee Gird

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords