CMAX 600 Augered Pile Rig for Sale on Okorder.com

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX series spiral pile drill rig is a new type of simple drilling equipment with independent innovation, ideal for pile construction in solar panels, billboards, street lamp, fences, flagpoles, traffic signs, isolation net and simple houses, giving strong stratum adaptability and high efficiency.

◆ The rig is equipped with a large torque rotary head for strong power, which provides strong adaptability in stratum.

◆ The hydraulic system adjusts rotation and feed to the stratum conditions accurately, which ensures high drilling efficiency.

◆ The rig is equipped with a pile guide device to guarantee pile verticality and quality.

◆The rig can be equipped with various pile connecting devices according to the pile structure and size, which makes pile insertion flexible and efficient.

◆ In different stratum condition, the rig can be equipped with down-the-hole percussion, cutting, short spiral and other tools to achieve full stratum drilling.

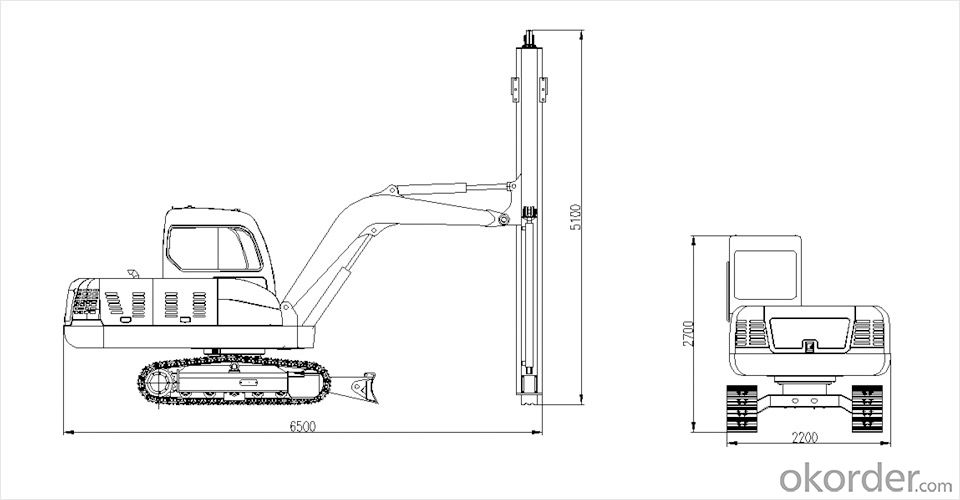

| MAIN DATA | UNIT | SWDL600 |

|---|---|---|

| OPERATION PARAMETER | ||

| Pile diameter | mm | 76~90 |

| Pile depth | m | 3 |

| CHASSIS | ||

| Track base | mm | 2240 |

| Gauge | mm | 1680 |

| Crawler width | mm | 400 |

| Ground clearance | mm | 340 |

| Blade length | mm | 2080 |

| ENGINE | ||

| Model | V3300-DI | |

| Displacement | L | 3.3 |

| Power/Speed | kW/rpm | 54.9/2600 |

| Fuel tank capacity | L | 140 |

| FEED | ||

| Length of drillrig | mm | 4800 |

| Feed length | mm | 3500 |

| Feed speed | m/min | 3 |

| Feed force | kN | 30 |

| TRAVELLING | ||

| Travel speed | km/h | 4.5/3.1 |

| Traction force, max | kN | 55 |

| Hill climbing ability | ° | 25 |

| ROTARY | ||

| Rotary speed, max | rpm | 40 |

| Rotary torque, max | Nm | 6000 |

| ENSION | ||

| Gross weight | t | 7.8 |

| Diamension(L×W×H) | m | 8.5×2.2×3.15 |

Advantages

1 sincere

CNBM International is a state company, now is one of the largest state-owned group cooperation in China! All the outdoor heaters produced by CNBM are compliant with the national level quality.

2 professional

Our engineers will at your services 24hours to answer your questions. Our goal is to provide the best professional services.

3 quality

CNBM International’s outdoor heater have strict quality control, only the best quality products can pass the test.

4speed

We have professional sales team to guarantee your reply within 12hours to save your precious time.

5 After sales

If the tower crane has any problems, we will solve your problems in first time.

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q:The difference between diesel pile driver and impact drilling machine

- Percussive drill: like percussive drilling, it is drilled out during impact.

- Q:The working principle of a pile driver ship

- The piling ship is equipped with a pile hammer, a pile stand, and auxiliary equipment.

- Q:What are the types of pile drivers?

- Pile driver is composed of pile hammer, pile support and auxiliary equipment. The pile hammer is attached to two parallel vertical guide rods (commonly called Longmen) at the front of the pile support and hoisted with lifting hooks. The pile foundation is a steel structure tower with a windlass at the back of which is used to lift the pile and hammer. A guide frame consisting of two guide rods is used in front of the pile to control the direction of the pile driving so that the pile can be accurately penetrated into the formation in accordance with the design orientation. The basic technical parameters of a pile driver are impact weight, impact kinetic energy and impact frequency.

- Q:How do I maintain the hydraulic pile driver I bought?

- the workload of the project; the geographical environment of the project; and the price the boss expects.

- Q:I heard that the operation of the pile driver can make about ten thousand a month, is it possible? It sounds a bit dodgy. Who knows about this job? Please tell me how much you can make it for a month

- Generally similar, but if the site is more, then more than this money

- Q:Is the lever of the pile driver fast?

- Wylong machinery piling machine organic lock rod, have lock rod grinding machine, the lock rod piling machine stone concrete ground relatively quickly, the lock rod grinding play the soil faster.

- Q:I have two pile drivers, followed by engineering piling, what qualifications do you need?

- Hang on it, for qualification trouble. You can contact me if you need to buy piling equipment.

- Q:What are the requirements for lime mud piling machine?

- On the whole, the more sticky the better, but some places are not so good, economically speaking, just take it. I'm a driver of the piling machine. Contact me if you need me

- Q:What's the difference between a amd bulldozer and a pile driver?

- AMD is the APU architecture, you can understand that the bulldozers for the powerful pipeline, row slowly push forward, side by side work, quad core four line outThe piling machine is on both sides of the 4 Alice type, 2 core graphics processor are respectively divided into 2 streams,

- Q:What machinery is used for piling?

- In fact, in some places with artificial, you can go to buy a wylong machinery piling machine equipment is good, driving fast and convenient and money

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX 600 Augered Pile Rig for Sale on Okorder.com

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords