Cloth Tape Nature Rubber Adhesive CG-50R Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Cloth Tape is of polyethylene cloth as the carrier, coating with hot melt adhesive, synthetic rubber adhesive or nature rubber. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

General purpose of Cloth Tape: widely used for pipe wrapping, gaffers and book binding etc.

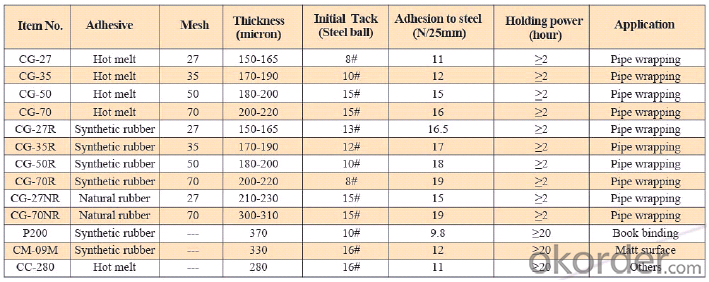

Typical Physical Reports of Cloth Tape:

The thickness of the tape can be customized.

Log Roll: Length 1000mm; width 1060mm.

Cut Roll: As per customer’s requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Cloth Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q:How do I seal a package securely with packaging tape?

- To seal a package securely with packaging tape, follow these steps: 1. Start by ensuring that the items inside the package are properly arranged and secured. 2. Cut a piece of packaging tape slightly longer than the width of the box. 3. Place the tape across the center of the box, ensuring it covers the flaps and overlaps on both sides. 4. Firmly press down on the tape to ensure it adheres properly to the surface. 5. Repeat this process with additional strips of tape, placing them parallel to the first strip and overlapping them slightly. 6. For added security, place strips of tape diagonally across the top and bottom flaps, creating an "X" pattern. 7. Apply pressure to the entire length of each strip to ensure a strong bond with the surface. 8. Finally, test the seal by gently tugging at the tape to ensure it holds firmly. By following these steps, you can seal your package securely with packaging tape, minimizing the risk of damage during transit.

- Q:How do you remove packaging tape without leaving residue?

- To remove packaging tape without leaving residue, you can try using a hairdryer to gently heat the tape. This will help loosen the adhesive, making it easier to peel off without leaving any sticky residue behind. Additionally, using a rubbing alcohol or vinegar solution can help dissolve any stubborn residue that may be left behind. Just apply the solution to a cloth and gently rub the area until the residue is gone.

- Q:Can packaging tape be used for sealing packages with electronics or electrical components?

- Yes, packaging tape can be used for sealing packages with electronics or electrical components. However, it is important to note that not all packaging tapes are suitable for this purpose. When selecting a packaging tape for sealing packages with electronics or electrical components, it is recommended to choose an anti-static or ESD (electrostatic discharge) safe tape. These tapes are specifically designed to prevent static electricity from damaging sensitive electronic components during shipping or handling. Using regular packaging tape without anti-static properties may pose a risk of static discharge that could potentially damage the electronics or affect their performance. Therefore, it is crucial to consider the specific requirements of the electronics or electrical components being packaged and select an appropriate tape to ensure their protection.

- Q:What is the difference between acrylic and hot melt adhesive for packaging tape?

- Packaging tape commonly utilizes two types of adhesives: acrylic and hot melt. These adhesives possess distinct characteristics that set them apart. A significant disparity lies in their bonding strength. Hot melt adhesive boasts exceptional bonding strength, making it ideal for heavy-duty applications. It creates a robust and durable bond that can withstand rigorous handling and varying temperatures. Conversely, acrylic adhesive typically offers a lower level of bonding strength in comparison. While still suitable for most general packaging requirements, it may not be the best choice for heavy or bulky items. Another distinction can be found in the application process. Hot melt adhesive is applied in a molten state and solidifies once cooled. Typically, it is dispensed using a hot melt glue gun or applicator. The quick setting time of hot melt adhesive allows for swift packaging operations, making it popular in high-volume settings. On the other hand, acrylic adhesive is applied in a liquid form and requires some time to cure and establish a strong bond. It can be applied using a hand dispenser or tape gun, and optimal adhesion often necessitates some pressure. Moreover, hot melt adhesive demonstrates excellent adhesion to a wide array of surfaces, including cardboard, plastics, and metals. Its versatility allows for usage with various packaging materials. While acrylic adhesive also adheres well to different surfaces, it may not exhibit the same level of compatibility with certain low-energy surfaces, such as polyethylene or polypropylene. Furthermore, temperature resistance is an essential factor to consider. Hot melt adhesive performs admirably in both high and low temperatures, maintaining its bonding strength. It can endure freezing temperatures and heat without compromising its adhesive properties. Acrylic adhesive, while generally offering good temperature resistance, may not be as effective in extreme conditions, particularly at very high or low temperatures. In conclusion, the primary disparities between acrylic and hot melt adhesives for packaging tape lie in bonding strength, the application process, surface compatibility, and temperature resistance. While hot melt adhesive provides superior bonding strength, rapid setting time, and excellent temperature resistance, acrylic adhesive offers versatility, ease of application, and good adhesion to most surfaces. The choice between the two depends on specific packaging needs, materials used, and environmental conditions.

- Q:Is packaging tape resistant to extreme temperatures or weather conditions?

- Packaging tape is generally designed to be resistant to extreme temperatures and various weather conditions. However, the level of resistance may vary depending on the specific type and quality of the tape. Most packaging tapes are made from materials like polypropylene or PVC, which are known for their durability and ability to withstand different environmental factors. These tapes are often treated with special adhesives that can maintain their stickiness even in extreme temperatures or humid conditions. In terms of extreme temperatures, packaging tapes are typically designed to withstand a wide range of temperatures, including both low and high extremes. They can usually endure temperatures as low as -20 degrees Celsius or as high as 60 degrees Celsius without losing their adhesive properties or becoming brittle. Similarly, packaging tapes are engineered to be resistant to various weather conditions. They are designed to resist moisture, humidity, and UV radiation, which are common elements that can deteriorate the quality of the tape. This resistance ensures that the tape remains intact and effective, even when exposed to rain, snow, or direct sunlight. It is important to note that while packaging tape is generally resistant to extreme temperatures and weather conditions, prolonged exposure to such conditions can still impact its durability. Therefore, it is advisable to store and use packaging tape in a controlled environment whenever possible to ensure maximum effectiveness.

- Q:Can packaging tape be used for sealing cardboard boxes?

- Yes, packaging tape is commonly used for sealing cardboard boxes as it provides a strong and secure bond.

- Q:Does packaging tape come in different dispenser options for ease of use?

- Yes, packaging tape does come in different dispenser options for ease of use. There are various types of dispensers available in the market that are specifically designed to make the task of sealing boxes or packages easier and more convenient. These dispensers come in different sizes, styles, and functionalities to cater to different needs and preferences. One common type of dispenser is the handheld dispenser, which is lightweight and compact, making it easy to handle and maneuver. These dispensers often have a serrated blade for cutting the tape and a comfortable grip for better control. They are ideal for small to medium-sized packaging tasks. For larger packaging jobs, there are also tabletop or benchtop dispensers available. These dispensers are designed to sit on a surface and hold the tape roll securely in place, allowing for efficient and continuous taping. They often have a built-in cutting mechanism for easy and precise tape cutting. Furthermore, there are automatic or electric dispensers that take convenience to the next level. These dispensers can automatically dispense and cut the tape with the push of a button, reducing the effort and time required for packaging tasks. They are particularly useful for high-volume or repetitive packaging needs. In summary, packaging tape does come in different dispenser options to suit various preferences and requirements. Whether you need a handheld dispenser for small tasks or an automatic dispenser for larger volumes, there are dispenser options available that can enhance the ease of use and efficiency of your packaging process.

- Q:Is packaging tape resistant to chemicals?

- Yes, packaging tape is typically resistant to chemicals. It is designed to withstand various substances and maintain its adhesive properties, making it an effective choice for securing packages and protecting their contents.

- Q:Belt business is a big profit

- Set up adhesive tape factory, unlimited prospects, the market permanent, one-time investment, lifelong income. Investment is not large, broad market prospects, products close to people's lives, products unique, lucrative productsProduct price is reasonable, "do adhesive tape production plant" whether to meet the above six factors?:The open tape production plant, according to the geographical size, its ability to invest, investment funds may be less than, generally thirty thousand yuanLeft and right can be opened.With the rapid growth of market economy, tape market demand is also growing, according to the [magazine] packaging industry news report, [],In 2005, China's tape production and sales volume of about 3 billion volumes, the market prospect is very broad, can be described as unlimited business opportunitiesThe tape is a traditional industry, every household will need to use the tape, business is more manufacturers cannot do without tape.

- Q:Can packaging tape be used for sealing foam or bubble wrap?

- Yes, packaging tape can be used for sealing foam or bubble wrap. Packaging tape is designed to have a strong adhesive that adheres well to various surfaces, including foam and bubble wrap. By applying packaging tape to the edges or seams of foam or bubble wrap, you can securely seal and protect your items during shipping or storage. It is important to ensure that the tape is applied properly and firmly to provide a tight seal and prevent the foam or bubble wrap from coming loose.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cloth Tape Nature Rubber Adhesive CG-50R Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords