Clear Tempered Glass with 3C/CE/ISO Certificate 3mm-19mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Clear Tempered Glass:

TEMPERED GLASS is made by heating flat glass to just below its softening temperature (650 °c) and suddenly chilling it with jets of cold air. It results in the outer skins under powerful compressive stress and the interior with severe tensile stress. In consequence, the impact applied to the glass will be overcome by the compressive stress on the surfaces to assure safety of use. It is ideal for areas with high wind loads and areas where human contacts are an important consideration.

2.Main features of Clear Tempered Glass:

.5 times harder than ordinary float glass, stronger resistance to thermal breakage than annealed or heat strengthened glass.

.Once breakage occurs, the glass disintegrates into small cubical fragments, which are relatively harmless to human body.

.It withstands abrupt temperature change of 220 Centigrade.

.Sizes are produced as per customer request. Once tempered, it can not be cut down.

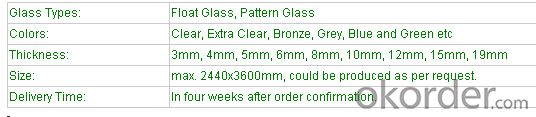

3.Clear Tempered Glass:

4.Clear Tempered Glass Specification:

5.Our factory

6.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Twilight wall hollow glass with glass Zha glue with what is best?

- The raw materials of the latter two kinds of insulating glass are glass, aluminium strip, insert angle, butyl glue, double component polysulfide glue or silicone rubber, drying agent and compound sealant.

- Q:Is it a vacuum cup with fluorine coating that affects the health?

- Does not affect the health, only in the temperature of more than 200 degrees will be long life of harmful substances.

- Q:How to seal the glass fiber reinforced plastic mould?

- Considering the type of FRP mould surface is different from the rubber mold so complicated, is generally flat front, so it is recommended to do a Z type mold, pre buried iron screws for back. As long as the screw is properly distributed, it will not leak. Can again, in the mold a good brush coat, also a little gel in the mold parting surface, or glass glue or strips of clay on a concave groove (note the hardness of sludge in winter). The old mold leaks in detail and the sludge is blocked.

- Q:The glass door in the shower room is too heavy. What material can be substituted, which is as transparent as glass but lighter than glass?

- Glass material mainly has three parts: basic material, flux and colorant, and also includes decoloring agent, clarifying agent and corrosion inhibitor* basic materials for glass makingSilica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q:How is glass made? What is its raw material?

- The chemical composition of ordinary glass is Na2O, CaO, 6SiO2, the main component is silica, is a kind of amorphous structure with irregular structure. Widely used in buildings for wind and light transmission; of mixtures. There is also colored glass mixed with certain metal oxides or salts, and toughened glass made by special methods. Sometimes some transparent plastic (such as polymethyl methacrylate) is also called organic glass.

- Q:What kind of raw material is glass made of?

- Composition of common glass chemical oxides (Na2O, CaO, 6SiO2)Glass is usually divided into oxide, glass, and non oxide glass by major components. Non oxide glass varieties and a small number, mainly sulfur glass and halide glass. Chalcogenide glass anion for sulfur, selenium and tellurium, can stop short wave light by yellow, red, and near infrared light, which has low resistance, switching and memory characteristics. Having low refractive index, low dispersion, and often used as optical glass.

- Q:Is glass fiber reinforced metal material?

- The advantages include soft and hard, corrosion resistance, aging resistance, waterproof and insulation, high mechanical strength, recycling, can replace steel manufacturing machine parts, it is used in manufacturing a variety of sports equipment, shell pipeline, shipbuilding, automobile and electronic products and printed circuit board.

- Q:The difference between natural crystal and crystal glass, merits and demerits!

- Crystal glass according to PBO (lead oxide) content is divided into high (24%PBO and above), medium (18%PBO), low (12%-16%PBO) three grades. Grading standards are similar to gold. International standard crystal glass is 24%PBO, so merchants will also call this class "24K"". If you go to buy, say some similar "jargon", the other party will feel that you are more adept, encountered illegal businesses, nor dare to fool you.

- Q:Does fiberglass contain formaldehyde? I'm a hair salon. Buy a glass fiber reinforced plastic shampoo bed, there is always a pungent smell of the body, there is no harm to it, including formaldehyde free

- Because of the different kinds of resins used, they are called polyester glass fiber reinforced plastics, epoxy glass fiber reinforced plastics and phenolic resin glass fiber reinforced plastics. The main raw materials of glass fiber reinforced plastics are resin, curing agent and glass fiber. Glass fiber is not toxic, but contact the skin will be itching. And resin and curing agent have certain harm to human body, especially curing agent, if it is the curing agent of aromatic amine, that is relatively harmful to human body.

- Q:How to distinguish between good and bad glass fiber reinforced plastic?

- High quality glass steel products appearance has no obvious cracks, pores are less pure, bright color, good transparency, toughness has a certain strength, good surface smoothness, long service life; while the poor quality of the glass steel product surface crack, more pores, mixed color gloss is not enough. Its service life is also short.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Clear Tempered Glass with 3C/CE/ISO Certificate 3mm-19mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords