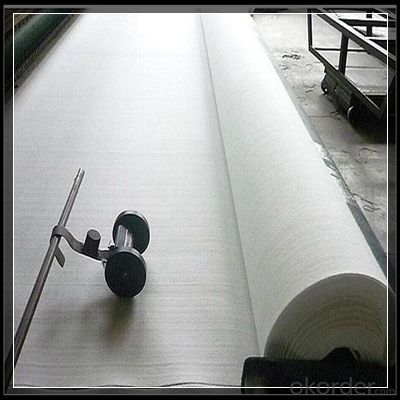

Civil Non-woven Geo textile Industrial Nonwoven fabric with High Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Geotextile fabric application requires observing the requirements of the following normative and technical documentation on draining, separating and enforcing inter-layers in road constructions, foundations, earthworks, and melioration construction, drainage systems, pipe lines laying, airport and waste disposal area constructions.

Assembling is possible at almost any weather conditions. There are no big difficulties while the laying out of the material due to the following features: material rolls are not big, which reduces transportation and storage costs as well as labor costs; the material does not water permeable; while application in humid conditions the roll weight does not change; it is not permeable for plant roots, is a good protection from gnawing animals; acid and alkali resistant, etc. the material exactly repeats the base molding and does not require any fixing and fastening joints.

1. Geotextile Specifications

1) Weight / Mass: 100g/m2-1500g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

5) Color: Black , white , grey and other color

6) Certificate: CE/ISO9001 , ISO14001

7) Manufacturing method: nonwoven / woven

Features and Benefits

Nonwoven structure, providing excellent surface friction and built-in elongation

Effective filter, with tight pore size (AOS=70) and high permittivity

High tensile strength, with excellent puncture and tear resistance

Range from 3.2 oz/sy (109g/sm) – 16.0 oz/sy (543g/sm)

Thick structure, allowing cushioning and lateral gas and liquid transmission

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:What are the installation guidelines for geotextiles used in erosion control blankets?

- The installation guidelines for geotextiles used in erosion control blankets typically involve the following steps: 1. Site preparation: Ensure that the area where the erosion control blanket will be installed is properly graded and free of any debris or vegetation. 2. Unroll the geotextile: Start by unrolling the geotextile fabric along the slope or area where erosion control is needed. Make sure to overlap the fabric by the specified amount to ensure complete coverage. 3. Secure the fabric: Use stakes or landscape pins to secure the geotextile to the ground, especially at the edges and corners. This will prevent it from shifting or being displaced during installation or heavy rainfall. 4. Seam connection: If multiple rolls of geotextile fabric are required, ensure that they are properly overlapped and securely connected using a recommended seam connection method. This will ensure a continuous and seamless coverage. 5. Anchoring: In certain cases, additional anchoring may be required to provide extra stability. This can include using sandbags, rocks, or other suitable materials along the edges or across the surface of the geotextile fabric. 6. Vegetative cover: If the erosion control blanket is designed to support vegetation growth, follow the recommended guidelines for seed or plant installation. This may involve spreading seeds or planting live vegetation through the geotextile fabric. It is important to note that these guidelines may vary depending on the specific erosion control blanket and geotextile manufacturer, as well as the site and project requirements. It is always recommended to refer to the manufacturer's installation instructions and consult with a professional engineer or erosion control specialist for proper installation and best results.

- Q:Geotextile GB and Dahua What is the difference between looking at almost ah

- GB is the current national industry standards, Dahua is from the raw materials to distinguish, Huazhi geotextile material manufacturers

- Q:Geotextile 100 meters a roll is about how much diameter

- About 15 meters

- Q:How do geotextiles contribute to land reclamation projects?

- Geotextiles contribute to land reclamation projects by providing erosion control, soil stabilization, and drainage solutions. They act as a barrier between the underlying soil and overlying materials, preventing soil erosion caused by wind or water. Geotextiles also help stabilize the soil, allowing vegetation to grow and preventing the formation of unstable slopes or embankments. Additionally, they aid in efficient drainage, ensuring proper water flow and preventing waterlogged conditions that could hinder the reclamation process. Overall, geotextiles play a crucial role in land reclamation projects by enhancing the stability and productivity of reclaimed land.

- Q:How do geotextiles contribute to groundwater recharge?

- Geotextiles contribute to groundwater recharge by acting as a permeable barrier that allows water to infiltrate the soil while preventing soil erosion. This helps to retain and replenish groundwater levels by promoting the natural process of water percolation and recharge into aquifers.

- Q:How do geotextiles help with reinforcement of geogrid reinforced soil slopes?

- Geotextiles help with the reinforcement of geogrid reinforced soil slopes by acting as a separator and filter between the soil and the geogrid. They prevent the soil particles from passing through the geogrid openings, maintaining its stability and preventing the loss of soil material. Additionally, geotextiles distribute the load and stress evenly across the geogrid, enhancing its load-bearing capacity and overall performance in reinforcing the soil slope.

- Q:What are the key considerations for geotextile installation in high water flow areas?

- Some key considerations for geotextile installation in high water flow areas include selecting a geotextile material with a high flow rate to allow for effective water drainage, ensuring proper anchoring and securing of the geotextile to prevent displacement, conducting thorough site investigations and assessments to determine the appropriate installation method and design, and monitoring the performance of the geotextile over time to identify any maintenance or repair needs. Additionally, considering the environmental conditions and potential impact on the geotextile's durability is crucial in high water flow areas.

- Q:How do geotextiles help in the separation of materials?

- Geotextiles help in the separation of materials by creating a barrier between different layers of soil or aggregates. They prevent the mixing and migration of materials, such as preventing the intermixing of fine and coarse particles, thereby maintaining the integrity and stability of the construction or landscaping project.

- Q:Can geotextiles be used in land reclamation projects?

- Yes, geotextiles can be used in land reclamation projects. They are often utilized for erosion control, soil stabilization, and drainage purposes in these projects. Geotextiles help to prevent soil erosion and provide a stable base for vegetation growth, making them a valuable tool in land reclamation efforts.

- Q:How do geotextiles help with asphalt pavement reinforcement?

- Geotextiles help with asphalt pavement reinforcement by providing a strong and stable foundation for the asphalt layer. They prevent the mixing of different soil layers, reducing the risk of settlement and rutting. Geotextiles also enhance the pavement's load-carrying capacity and increase its lifespan by distributing the load more evenly. Additionally, they help in reducing cracking and water infiltration, thereby improving the overall performance and durability of the asphalt pavement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Civil Non-woven Geo textile Industrial Nonwoven fabric with High Stabilization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords