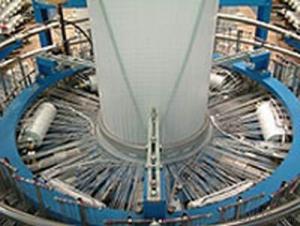

Circular Knitting Machine for Making Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 5 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

18-feeder computerized artificial fur plain color circular knitting machine can knit the fur&cotton sliver with high quality.

MS18-A 18-feeder computerized artificail fur plain color circular knitting machine can knit the fur&cotton sliver with high quality.

Main specifications and technical features of the MS18-A 18-feeder computerized artificial fur plain color circular knitting machine:

1. With complete up-to-date computer-controlled system, the state of working equipment, automatic fault diagnosis, automatic alarm or other related records could be displayed on the screen.

2. New added technology of broken needle detector improves the quality of jacquard knitting effectively.

3. The head of comb is designed to be more reasonable while the feeding speed and quantity is controlled more effectively, which make it adjustable according to the differences of fabric material, widening its practical scope.

4. The design of adjustable tile can keep those rotating parts such as cylinders working in their best condition and rotating more smoothly and steadily. It can be much easier and more convenient to maintain the machines.

5. Cloth roller adapts magnetic-pull-control system, being the most advanced in the world. It is able to adjust the pull force according to requests, improving the fur weaving quality.

6. Both of ‘Uphil’ angle and ‘Downhil’ angle use advanced “A” and ”B” blocks in order to make working parts such as needle and sinker work with more accuracy and coordination. It is possible to make it a reality to freely change the blocks in the same places with similar blocks.

7. New improved density adjusting equipment provides convenience and accuracy to adjust density of every route, which makes it easy to adjust the machine and simple to operate.

8. The storage of cloth is increased, making it more suitable for production.

9. This product features the advantages of imported machines as respect to appearance and structure and may compare favorably with imported machines.

Cylinder Diameter | 24’’/610mm 27’’/686mm |

Cylinder Grade | E14/1056(24’’) E12/1056(27’’) E14/1176(27’’) |

Feeds Routes | 18 |

Cylinder Speed | 40r/min |

Main Motor Power | 7.5kw |

Weaving Needles Model | 88.82 |

Installation Size(LWH) | 3325mm,2510mm,3425mm |

Woven Geotextiles Data Sheet

Item | Testing Method | Unit | ||

Grad Tensile Strength | ASTM-D 4632 | N | 890 | 1405 |

Grab Elongation | ASTM-D 4632 | % | ≤20 | ≤20 |

Puncture Strength | ASTM-D 4833 | N | 400 | 667 |

CBR Puncture | ASTM-D 6241 | N | 3200 | 4800 |

Mullen Burst | ASTM-D 3786 | kPA | 2578 | 4137 |

Trapezoidal Tear | ASTM-D 4533 | N | 500 | 750 |

Apparent Opening Size | ASTM-D 4751 | mm | 0.425 | 0.425 |

Permittivity | ASTM-D 4491 | Sec-1 | 0.05 | 0.05 |

Water Flow Rate | ASTM-D 4491 | 1/m/m2 | 163 | 163 |

UV Resistance | ASTM-D 4355 | % 500hrs | 70 | 70 |

Roll Width | m | 6 | 6 | |

Roll Length | m |

100 | 100 | |

Mass | GSM | 200 | 300

|

- Q:How do geogrids help in reducing the risk of foundation settlement?

- Geogrids help in reducing the risk of foundation settlement by providing reinforcement and stability to the soil. They distribute the load from the foundation evenly, preventing excessive settlement or shifting of the soil. This helps to maintain the structural integrity of the foundation and minimize the potential for settlement-related damage.

- Q:Can geogrids be used in soil stabilization for agriculture?

- Yes, geogrids can be used in soil stabilization for agriculture. Geogrids are commonly used in various soil stabilization applications, including agriculture, to improve soil strength, prevent erosion, and enhance load-bearing capacity. They help in stabilizing the soil by providing reinforcement and distributing loads, which is essential for promoting healthy crop growth and preventing soil erosion in agricultural lands.

- Q:Can geogrids be used in reinforcement of retaining walls?

- Yes, geogrids can be used in the reinforcement of retaining walls. Geogrids are commonly used in retaining wall construction to enhance the stability and strength of the structure. They are typically placed within the soil layers of the wall to distribute the lateral forces and increase the overall resistance to soil movement. This reinforcement technique helps to prevent the wall from overturning or sliding, ensuring its long-term stability.

- Q:The dam is protection of geomembrane or gabion.

- There is a need to gabion can call ID

- Q:Can geogrids be used in temporary construction access mats for environmentally sensitive areas?

- Yes, geogrids can be used in temporary construction access mats for environmentally sensitive areas. Geogrids are commonly used in construction projects to provide stabilization and reinforcement to the ground. They are designed to distribute weight and reduce ground pressure, making them suitable for protecting sensitive areas from damage caused by heavy construction equipment or vehicles. Additionally, geogrids are often made from environmentally friendly materials and can be easily removed and reused, minimizing their impact on the environment.

- Q:Can geogrids be used in landfill liners?

- Yes, geogrids can be used in landfill liners. They are often used as part of a composite liner system to enhance the stability and performance of landfill liners. Geogrids provide reinforcement and improve the tensile strength of the liner, helping to prevent soil erosion and enhance the overall integrity of the landfill liner system.

- Q:Fiberglass geogrid is mainly used for old road reconstruction, the main purpose is to reduce reflection

- Geotextiles are used for road, railway, tunnel, dam, tailings treatment, isolation, filtration, drainage, reinforcement, protection and enhancement...Analysis of the causes of cracks in the asphalt overlay, the formation of a new type of excellent geotechnical substrates by special coating process.Asphalt overlay on old cement concrete pavement is a kind of special pavement structure, and its stress and strain characteristics are quite different from those of general elastic layered system.

- Q:What are some common standards and specifications for geogrids?

- Some common standards and specifications for geogrids include the ASTM D6637 standard for uniaxial geogrids, the ASTM D6917 standard for biaxial geogrids, and the ISO 10318 standard for geosynthetics. These standards outline requirements for geogrid properties such as tensile strength, elongation, aperture size, and durability, ensuring quality and consistency in geogrid products.

- Q:How to do this in the geogrid in the retaining wall? Is there any remedy?

- High tensile strength and low elongation glass fiber geogrid is a glass fiber as raw material, has a high resistance to deformation, the elongation rate is less than 3%.

- Q:What is the recommended installation method for geogrids?

- The recommended installation method for geogrids is to first prepare the subgrade by removing any vegetation or loose soil, and then compact the subgrade to achieve a stable base. The geogrid should be unrolled and placed on top of the prepared subgrade, ensuring it is stretched and anchored securely at the edges. Overlapping the geogrid panels by the manufacturer's recommended amount and using connector devices may be necessary. Finally, the geogrid should be covered with an appropriate fill material and compacted in layers to ensure proper integration and load distribution.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Circular Knitting Machine for Making Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 5 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords