Chrome Steel Ball (G10) /52100 Balls/Bearing Ball/Steel Shot/Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

ASTM

Technique:

Hot Rolled,Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

g10

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

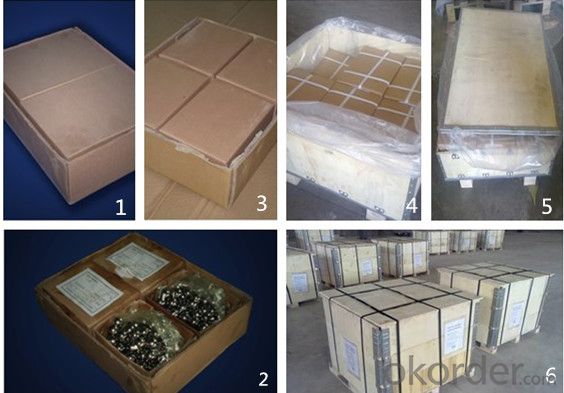

Packaging:

Standard Export Packing

Our company is a professional AISI 52100 15.875mm-150mm G10-GG1000 chrome steel ball manufacturer for more than two decades. Before reformation, it is the joint venture with LYC.

Production procession

According to the ISO9001, we have established the strict & perfect quality assurance system, making sure that the whole production process is controlled and steady quality is offered to satisfy customers.

Composition of Different Materials

| Material | Chemical of Different Materals | ||||||||

| C | SI | Mn | P | S | Ni | Gr | Mo | Cu | |

| AISI440C | 0.95-1.20 | 1.00max | 1.00max | 0.040max | 0.030max | 0.60max | 16.00-18.00 | 0.75max | _ |

| AISI420C | 0.42-0.50 | 1.00max | 1.00max | 0.040ax | 0.030max | 1.00max | 12.5-14.5 | _ | 0.30max |

| AISI304 | 0.08max | 1.00max | 2.00max | 0.045max | 0.030max | 8.00-10.5 | 18.00-20.00 | _ | _ |

| AISI316 | 0.08max | 1.00max | 2.00max | 0.045max | 0.030max | 10.00-14.00 | 16.00-18.00 | 2.00-3.00 | _ |

| AISI E52100&GC r15 | 0.95-1.10 | 0.95-1.10 | 0.50max | 0.025max | 0.025max | _ | 1.30-1.60 | _ | _ |

Applications:

Chrome steel balls are applied in bearings such as slew bearing, deep groove ball bearing, thrust ball bearing, self aligning ball bearing, double-row bearing and etc.

Packing:

Carton box by wonden plates

our products are very well known in more than European and other foreign countries. your cooperation and order are warmly welcome!

- Q:What are the advantages of using steel products over other materials?

- There are several advantages of using steel products over other materials. Firstly, steel is incredibly strong and durable, making it suitable for a wide range of applications. It has a high tensile strength, meaning it can withstand heavy loads and resist deformation. Additionally, steel is highly resistant to corrosion, making it ideal for outdoor or maritime use. Moreover, steel is recyclable, making it a sustainable choice. It can be easily melted down and reused without losing its properties. Lastly, steel offers versatility in terms of design and can be easily customized to meet specific requirements. Overall, the advantages of using steel products include strength, durability, corrosion resistance, sustainability, and design flexibility.

- Q:What are the different types of steel products used in the oil and gas industry?

- There are several types of steel products used in the oil and gas industry, including pipes, tubing, casings, and fittings. These products are commonly made from carbon steel, alloy steel, or stainless steel, depending on the specific application and requirements. Carbon steel is often used for general-purpose applications, while alloy steel is preferred for more demanding conditions such as high-pressure or high-temperature environments. Stainless steel is chosen for its corrosion resistance in aggressive or corrosive environments.

- Q:How are steel products used in the aerospace and aviation industry?

- Steel products are widely used in the aerospace and aviation industry for their strength, durability, and resistance to high temperatures. They are utilized in various components such as aircraft frames, engine parts, landing gear, and structural elements. Steel's properties make it an ideal material for ensuring the safety and reliability of aircraft, as it can withstand extreme conditions and support heavy loads.

- Q:How is steel used in the construction of underground utilities?

- Steel is commonly used in the construction of underground utilities due to its strength, durability, and resistance to corrosion. It is used for various applications such as pipes, conduits, and casings to transport essential utilities like water, gas, and electricity. Steel's ability to withstand high pressure, load-bearing capacity, and long-term reliability make it an ideal choice for ensuring the integrity and safety of underground infrastructure.

- Q:How are steel products used in the manufacturing of furniture?

- Steel products are commonly used in the manufacturing of furniture to provide structural support and durability. Steel is used for constructing frames, legs, and other components, ensuring the furniture can withstand heavy weight and frequent use. Additionally, steel can be molded or shaped into various designs, enabling furniture manufacturers to create unique and modern pieces.

- Q:What are the cost implications of using steel products in various applications?

- The cost implications of using steel products in various applications can vary depending on factors such as the type and grade of steel, the complexity of the application, and the market conditions. Generally, steel products tend to have higher initial costs compared to some other materials, but they often offer long-term cost benefits due to their durability, strength, and low maintenance requirements. Additionally, the cost of steel can be influenced by factors such as production volumes, transportation costs, and market demand. Overall, while steel products may have higher upfront costs, their long-term benefits often outweigh the initial investment.

- Q:What are the different types of steel bolts and their uses in automotive assembly?

- There are several types of steel bolts commonly used in automotive assembly. These include hex bolts, flange bolts, shoulder bolts, and carriage bolts. Hex bolts, also known as hex head bolts or cap screws, have a six-sided head and are used to fasten various components in the automotive assembly process. They are versatile and can be tightened or loosened using a wrench or socket. Flange bolts have a flange (a wider circular base) built into the head, which distributes the load and provides a larger surface area for better grip. These bolts are often used in applications where there is a need for high-strength and a secure connection. Shoulder bolts, also called shoulder screws or stripper bolts, have a cylindrical shoulder between the head and the threaded portion. They are commonly used in automotive assembly to secure rotating or sliding components, allowing for smooth movement while maintaining stability. Carriage bolts, also known as coach bolts, have a round, domed head and a square or ribbed neck beneath it. These bolts are primarily used in applications where the bolt head needs to be flush with the surface, providing a smooth and snag-free finish. Each type of steel bolt has its unique design and characteristics, making them suitable for specific automotive assembly tasks.

- Q:How is steel plate heat-treated for optimal strength?

- Steel plate is heat-treated for optimal strength through a process called quenching and tempering. First, the steel plate is heated to a high temperature, known as the austenitizing temperature, which allows the carbon in the steel to dissolve uniformly. It is then rapidly cooled by immersing it in a quenching medium, such as oil or water, to transform the crystal structure into a hard martensitic phase. Subsequently, the plate is reheated to a lower temperature and held for a specific period to temper the martensite, reducing its brittleness while maintaining a significant level of strength. This heat treatment method enhances the hardness, toughness, and overall mechanical properties of the steel plate, making it ideal for various applications requiring optimal strength.

- Q:How is steel plate cut using CNC machines for fabrication?

- Steel plate is cut using CNC machines for fabrication by following a step-by-step process. First, a digital design or blueprint is created using computer-aided design (CAD) software. This design is then converted into a program that can be understood by the CNC machine. The steel plate is securely clamped onto the machine's work surface, and the cutting tool, typically a high-speed rotating cutter or laser, is positioned above the plate. The CNC machine then moves the cutting tool along the programmed path, precisely cutting the steel plate according to the design. The machine's computer-controlled accuracy ensures that the cuts are made with high precision and repeatability.

- Q:How are steel forgings used in the aerospace industry?

- Steel forgings are widely used in the aerospace industry due to their exceptional strength, durability, and resistance to extreme conditions. These forgings are utilized in critical aerospace components such as landing gear, turbine discs, engine mounts, and structural parts. With their ability to withstand high temperatures and pressures, steel forgings ensure the reliability and safety of aircraft, enabling them to perform optimally in demanding environments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Chrome Steel Ball (G10) /52100 Balls/Bearing Ball/Steel Shot/Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords