Chrome Price Q235 CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

| GRADE | SIZE | APPLICATION |

| Q235 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon

| Q235 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.14-0.22 | 0.15-0.30 | 0.40-0.65 | 0.040% Max | 0.05Max |

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Packing & Delivery

1. Packaging: seaworthy package or as required

2. Delivery: 35-45 days or based on quantity

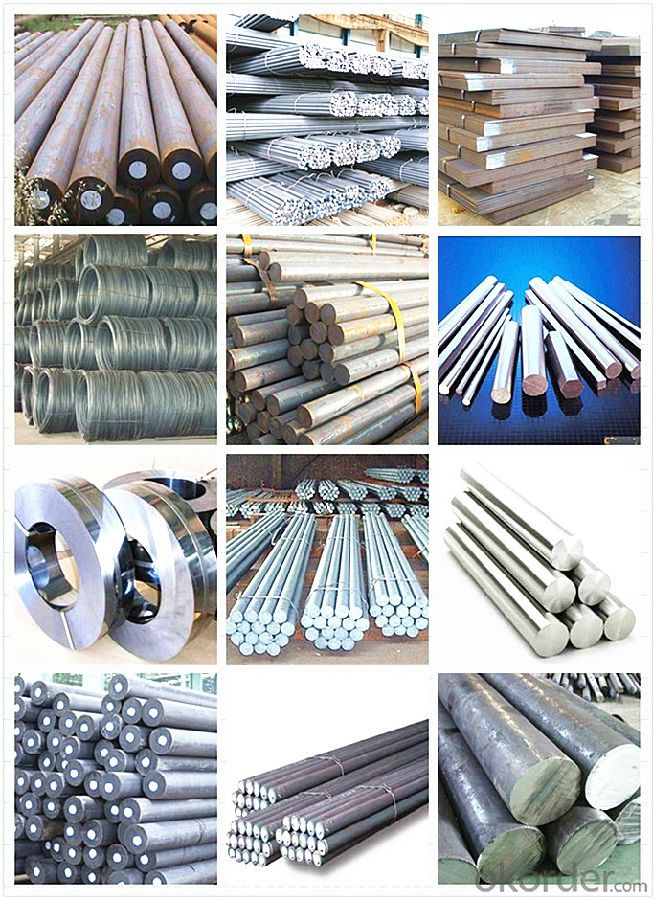

Products Show

Workshop

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q:What is the process of manufacturing special steel?

- The process of manufacturing special steel involves several steps. Firstly, raw materials such as iron ore, coal, and limestone are gathered and processed to create molten iron in a blast furnace. Next, impurities like carbon, sulfur, and phosphorus are removed through various refining techniques. Once the desired composition is achieved, the molten iron is transferred to a steelmaking furnace, where alloying elements like chromium, nickel, or manganese are added to impart specific properties. The mixture is then refined further to remove any remaining impurities and to adjust the temperature and composition. After refining, the molten steel is cast into various shapes such as blooms, billets, or slabs, depending on the desired end product. These primary forms are then subjected to hot rolling, forging, or extrusion processes to shape them into the desired final products, such as bars, plates, or wires. Finally, the manufactured steel undergoes heat treatment processes like annealing, quenching, or tempering to enhance its strength, hardness, and other mechanical properties. It is also subjected to quality control measures to ensure it meets the required specifications. Overall, the process of manufacturing special steel involves a combination of raw material preparation, refining, casting, shaping, heat treating, and quality control steps to produce steel with specific properties tailored to meet diverse industrial needs.

- Q:How does special steel contribute to the robotics industry?

- The robotics industry benefits greatly from the use of special steel, which plays a vital role in its advancement. To begin with, special steel alloys possess extraordinary mechanical properties that make them ideal for manufacturing various robotic components. These alloys provide exceptional strength, durability, and resistance to wear and tear. Consequently, robots built with special steel can operate efficiently and reliably even in demanding environments like manufacturing plants or hazardous locations. Furthermore, special steel alloys offer outstanding heat resistance and thermal stability, a crucial characteristic in robotics. As robots often generate significant heat during operations, special steel components can withstand high temperatures without deforming or losing their structural integrity. This capability ensures that robots can perform optimally without the risk of mechanical failures caused by heat-related issues. Additionally, the corrosion resistance of special steel is highly advantageous for the robotics industry. Robots are increasingly being used in diverse applications such as underwater exploration, chemical handling, and outdoor environments. In such cases, exposure to moisture, chemicals, or harsh weather conditions can lead to corrosion and degradation of robot parts. By utilizing special steel alloys, manufacturers can significantly prolong the lifespan of robotic systems, reducing maintenance costs and enhancing overall reliability. Moreover, special steel's magnetic properties are invaluable in the development of magnetic sensors and actuators used in robotics. These sensors enable robots to detect and interact with their surroundings, improving their autonomy and adaptability. On the other hand, magnetic actuators enable precise control and movement in robotic systems. Special steel's magnetic properties contribute to the efficiency, accuracy, and responsiveness of these components, allowing robots to execute complex tasks with precision. In conclusion, special steel plays a vital role in the robotics industry by providing the necessary materials for manufacturing robust, high-performance, and versatile robotic systems. The use of special steel alloys enhances strength, durability, and the ability to withstand extreme conditions, ensuring the reliability, efficiency, and functionality of these machines.

- Q:What are the different coating techniques for special steel parts?

- There are several different coating techniques that can be used for special steel parts. Some common ones include electroplating, powder coating, thermal spraying, and chemical vapor deposition. Each technique offers unique advantages and is chosen based on factors such as the desired coating properties, cost, and application requirements.

- Q:What are the main factors affecting the tensile strength of special steel?

- The main factors affecting the tensile strength of special steel include the composition of the alloy, the heat treatment processes used, the presence of impurities or defects, the grain size and structure, and the amount of cold work or strain hardening applied to the material. Additionally, factors such as the presence of residual stresses, the temperature at which the steel is tested, and the rate of loading can also influence the tensile strength of special steel.

- Q:What is the composition of special steel?

- The composition of special steel can vary depending on its intended use and the specific properties required. However, in general, special steel is typically an alloy of iron and carbon, with additional elements added to enhance its strength, toughness, corrosion resistance, or other desired characteristics. Some common elements that can be found in special steel compositions include chromium, nickel, manganese, molybdenum, vanadium, tungsten, and cobalt. These alloying elements are carefully selected and added in specific amounts to achieve the desired mechanical, physical, and chemical properties of the steel. The composition of special steel can be tailored to meet specific industry requirements, such as for applications in aerospace, automotive, oil and gas, or construction.

- Q:How does special steel contribute to the heat resistance of products?

- Special steel contributes to the heat resistance of products due to its unique properties and composition. It is specifically designed to withstand high temperatures without losing its strength or structural integrity. The inclusion of elements such as chromium, nickel, and molybdenum in special steel enhances its heat resistance by forming a protective oxide layer that prevents oxidation and corrosion at elevated temperatures. This enables products made with special steel to withstand extreme heat conditions, making them suitable for various applications in industries such as aerospace, automotive, and energy.

- Q:What are the different types of case-hardening steel?

- There are several different types of case-hardening steels, including carburizing steel, nitriding steel, and cyaniding steel. These steels are specifically designed to undergo a surface-hardening process, where the outer layer of the steel is made harder while maintaining a tough core. Carburizing steel is treated with carbon-rich materials to increase its carbon content, while nitriding steel is exposed to nitrogen to form a hard surface layer. Cyaniding steel is treated with cyanide salts to produce a hard and wear-resistant surface. Each type of case-hardening steel has its own specific properties and applications.

- Q:Does special steel have any magnetic properties?

- Depending on its composition and treatment, special steel can indeed possess magnetic properties. The primary constituent of steel is iron, which is inherently ferromagnetic and capable of being magnetized. However, the magnetic characteristics of steel can be influenced by the presence of other elements such as nickel, cobalt, and various alloys. For example, stainless steel, which contains chromium and nickel, is typically either non-magnetic or only weakly magnetic. Conversely, materials like tool steel or high-speed steel may exhibit more pronounced magnetic properties due to their specific composition and heat treatment. Consequently, it is crucial to take into account the precise type of special steel and its alloying elements when assessing its magnetic behavior.

- Q:What are the properties of stainless tool steel?

- Stainless tool steel possesses several important properties. Firstly, it exhibits high corrosion resistance, making it suitable for applications in moist or corrosive environments. Secondly, it demonstrates excellent hardness, allowing it to withstand heavy wear and maintain sharp cutting edges. Additionally, stainless tool steel has good toughness, enabling it to withstand impacts without breaking or chipping. Finally, it offers good dimensional stability, ensuring minimal distortion or warping during heat treatment or use. Overall, these properties make stainless tool steel an ideal material for various tooling applications.

- Q:How does special steel perform in aerospace applications?

- Special steel performs exceptionally well in aerospace applications due to its unique properties. It possesses high strength, excellent corrosion resistance, and exceptional heat resistance, making it ideal for manufacturing critical components such as turbine blades, landing gear, and structural frameworks. The use of special steel ensures the durability and safety of aerospace systems, enabling them to withstand extreme conditions, such as high temperatures and pressure, encountered during flight.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Chrome Price Q235 CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords